rainwears@163.com may@may-rain.com

rainwears@163.com may@may-rain.com Mon to Friday: 8.00 am - 7.00 pm

Mon to Friday: 8.00 am - 7.00 pm

High Quality Outdoor Kids Waterproof Windproof Raincoat - Custom Print

Introduction to Advanced Children's Outdoor Rainwear Solutions

In the rapidly evolving market for outdoor protective wear, the demand for high-performance children's apparel is paramount. Parents and institutions alike seek robust solutions that combine unparalleled protection with user comfort and aesthetic appeal. Our focus today is on the high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat – a product engineered to meet the stringent requirements of outdoor activities while offering extensive customization capabilities for brand differentiation and specific institutional needs. This article delves into the technical aspects, manufacturing precision, application versatility, and strategic advantages of this specialized rainwear.

Industry Trends and Market Dynamics in Children's Technical Apparel

The global market for children's outdoor apparel is experiencing significant growth, driven by increased awareness of the benefits of outdoor play and education, coupled with rising parental expectations for product safety and durability. Key trends influencing this sector include:

- Sustainability & Eco-friendliness: A growing preference for materials that are recycled, recyclable, or produced with minimal environmental impact. Manufacturers are increasingly adopting bluesign® certified fabrics or PFC-free Durable Water Repellent (DWR) coatings.

- Advanced Material Science: Integration of technical fabrics that offer superior waterproofing (hydrostatic head ratings often exceeding 10,000mm), breathability (MVTR > 5,000 g/m²/24h), and windproof properties, without compromising on comfort or flexibility.

- Safety Standards: Strict adherence to international safety standards, including child-safe designs (e.g., breakaway hoods, no drawstrings in certain areas), reflective elements for low-light visibility, and non-toxic materials (e.g., OEKO-TEX Standard 100 certification).

- Ergonomic Design: Focus on designs that allow for unrestricted movement, accommodate layering, and provide extended coverage. Features like large-space hoods, adjustable cuffs, and extended back hems are highly valued.

- Customization & Personalization: Brands and institutions are seeking customized solutions for unique branding, specific color schemes, and specialized features for schools, clubs, or events.

These trends underscore the market's shift towards sophisticated, multi-functional garments that support children's active lifestyles in diverse weather conditions, exemplified by products like the high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat.

Manufacturing Process Flow: Engineering Excellence

The production of a high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat involves a meticulous multi-stage process, ensuring precision, durability, and adherence to stringent performance benchmarks. Our manufacturing facility operates under ISO 9001:2015 quality management standards.

1. Material Sourcing & Inspection

- Materials: Primary fabrics include 100% Polyester Pongee, Nylon Taslan, or PU-coated Polyester, typically with a Ripstop weave for enhanced tear resistance. Membranes often employ advanced PU or PTFE laminates for superior waterproofing and breathability. DWR treatments are applied for initial water repellency. All materials are sourced from OEKO-TEX Standard 100 certified suppliers, guaranteeing absence of harmful substances.

- Pre-production Testing: Fabrics undergo tests for hydrostatic head pressure (e.g., EN ISO 811), water vapor transmission rate (MVTR, e.g., JIS L 1099 B1), tear strength (e.g., ASTM D1424), and colorfastness (e.g., ISO 105).

2. Precision Patterning & Cutting

- CAD/CAM System: Digital patterns are created and optimized for material yield and ergonomic fit, often featuring a 'large space' design for comfort and layering.

- Automated CNC Cutting: Fabric layers are precisely cut using CNC machinery, ensuring consistent dimensions and minimizing material waste.

3. Custom Printing & Branding (If Applicable)

- Screen Printing / Digital Sublimation: Utilizing eco-friendly, non-toxic inks, custom logos, patterns, or reflective graphics are applied with high durability and color retention. Techniques are selected based on fabric type and design complexity.

4. Assembly & Seam Sealing

- Industrial Sewing: Panels are assembled using specialized industrial sewing machines, ensuring strong, flat seams that minimize bulk.

- Heat-Seam Taping: Critical for waterproofing, all stitched seams are meticulously sealed with heat-applied waterproof tape. This process adheres to ISO 11092 standards, preventing water ingress at stitch points.

5. Component Integration & Finishing

- Hardware Integration: Zippers (YKK or equivalent, often waterproof), snaps, cord stoppers, and reflective elements are securely attached.

- Final Finishing: Includes hem adjustments, cuff attachments, and hood integration, often with adjustable features to enhance windproof capabilities.

6. Quality Control & Testing

- Waterproof Chamber Test: Random samples undergo simulated rain conditions to verify the integrity of waterproofing and seam sealing.

- Wind Tunnel Test: To confirm windproof performance and thermal retention under specific wind speeds.

- Durability & Abrasion Resistance: Testing to ensure the garment withstands typical wear and tear associated with children's outdoor activities.

- Visual Inspection: Every garment is inspected for defects, print quality, and adherence to design specifications before packaging.

Technical Specifications and Performance Parameters

The high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat is designed to offer a superior blend of protection, comfort, and durability. Below are typical specifications, subject to customization based on specific client requirements.

Product Specification Table

| Parameter | Specification / Value | Testing Standard |

|---|---|---|

| Primary Fabric Composition | 100% Polyester Pongee 240T, Ripstop or Plain Weave | ISO 1833-1:2020 |

| Waterproof Rating (Hydrostatic Head) | ≥ 10,000 mm H₂O | EN ISO 811:2018 |

| Breathability Rating (MVTR) | ≥ 5,000 g/m²/24h | JIS L 1099 B1 Method |

| Windproof Rating | 100% Windproof (0 CFM air permeability) | ASTM D737 |

| Seam Construction | Fully Seam-Sealed with Waterproof Taping | Internal Protocol (Water Spray Test) |

| Durable Water Repellent (DWR) | PFC-free Bionic-Finish® Eco or equivalent | AATCC 22 |

| Safety Compliance | OEKO-TEX Standard 100, REACH compliant, Child Safety Compliant (e.g., BS EN 14682) | Various Certification Bodies |

| Weight (Approx. for Size M) | 350 - 450 grams (depending on features) | Internal Measurement |

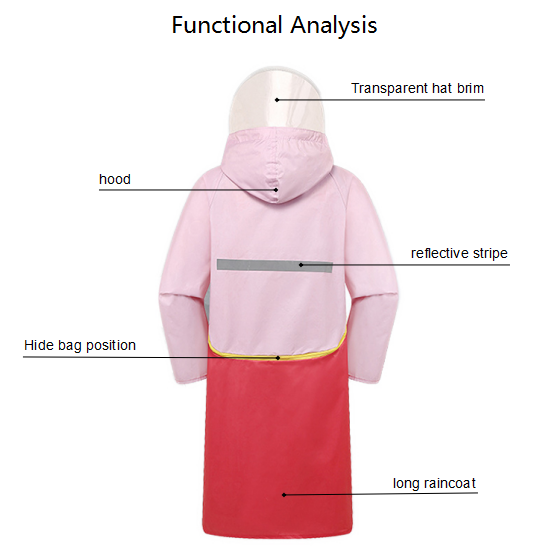

| Features | Large space hood, reflective elements, adjustable cuffs, storm flap, internal name tag | Design & Functional Review |

These specifications ensure that the raincoat provides optimal protection against severe weather conditions while maintaining a comfortable microclimate for the wearer.

Key Technical Advantages and Performance Benefits

The design and material selection for the high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat provide several critical advantages for B2B clients:

- Superior Weather Protection: With a hydrostatic head of ≥ 10,000mm and fully taped seams, the raincoat offers robust waterproofing, capable of withstanding heavy downpours for extended periods. The 100% windproof construction protects against chilling effects, maintaining core body temperature.

- Enhanced Breathability: A MVTR of ≥ 5,000 g/m²/24h ensures that perspiration can escape, preventing clamminess and overheating during active play, contributing to overall comfort and reducing the risk of dampness-related chills.

- Durability & Longevity: Constructed from high-denier polyester or nylon with ripstop options, and reinforced stress points, the raincoat is designed to endure the rigorous activities of children, offering a service life significantly longer than standard rainwear. This translates to a lower total cost of ownership for institutions.

- Optimized Safety Features: Incorporates child-safe design principles, including reflective piping for increased visibility in low-light conditions (e.g., early mornings, evenings), and secure, non-snagging closures. Materials are verified free from harmful substances via OEKO-TEX certification.

- Ergonomic & 'Large Space' Design: The generous cut accommodates layers of clothing underneath, allowing for seasonal versatility. The 'large space' hood design provides ample coverage without restricting peripheral vision, crucial for safety and comfort. Adjustable cuffs and hems further ensure a secure fit, sealing out wind and rain.

- Customization & Brand Integration: Our capabilities for custom printing allow for seamless integration of corporate logos, school crests, or specific branding elements, enhancing organizational identity and promotional reach.

Application Scenarios Across Target Industries

The versatility and robust performance of this raincoat make it ideal for a multitude of application scenarios and target industries:

- Educational Institutions (Schools, Kindergartens): Essential for outdoor learning programs, school trips, and daily commutes, ensuring children remain dry and comfortable regardless of weather. Custom printing allows for school uniforms or branding.

- Outdoor Adventure & Recreation Centers: For camps, forest schools, and adventure parks where children engage in extended outdoor activities. The durability and high performance are crucial for consistent protection.

- Retail & E-commerce Brands: Brands specializing in children's outdoor gear can leverage the technical specifications and customization options to offer premium products that meet discerning consumer demands.

- Travel & Tourism Operators (Family Segments): For tour companies organizing family-oriented excursions, especially in regions prone to unpredictable weather, providing reliable protective gear enhances customer experience.

- Corporate Gifting & Promotional Merchandise: Companies can utilize custom-printed raincoats as high-value promotional items for clients with families, or as part of CSR initiatives supporting children's welfare organizations.

- Event Management (Children's Events): For organizers of outdoor festivals, sports events, or themed parties where children's participation is key, ensuring comfort and protection.

In all these scenarios, the ability to provide a durable, protective, and branded solution like the high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat adds significant value.

Customized Solutions and Vendor Comparison

Our commitment to B2B partnerships extends to providing highly customizable solutions, differentiating our offerings from generic market alternatives.

Customization Capabilities:

- Custom Printed Designs: High-fidelity digital or screen printing for logos, patterns, or full-surface designs. Includes reflective prints for safety.

- Color Matching: Custom fabric dyeing to match specific brand guidelines or institutional colors (Pantone references).

- Sizing & Fit: Development of custom size charts beyond standard offerings, accommodating specific age groups or regional sizing requirements.

- Feature Integration: Options for specialized zippers, additional pockets, detachable hoods, integrated gloves/mittens, or alternative cuff closures (e.g., elastic vs. Velcro).

- Material Upgrades: Choice of more advanced membrane technologies, recycled content fabrics, or specific DWR treatments (e.g., C0, C6, C8 options).

Vendor Comparison Table: Premium vs. Standard Rainwear

| Feature | Our High-Quality Raincoat | Standard Market Offering |

|---|---|---|

| Waterproof Rating (Hydrostatic Head) | ≥ 10,000 mm (Fully taped seams) | 2,000 - 5,000 mm (Often un-taped or critically taped) |

| Breathability (MVTR) | ≥ 5,000 g/m²/24h | 1,000 - 3,000 g/m²/24h (or not specified) |

| Material Durability | Ripstop Polyester/Nylon, high denier, abrasion resistant | Basic Polyester, low denier, prone to tearing |

| Safety Certifications | OEKO-TEX 100, REACH, Child Safety Compliant | Limited or no specific certifications |

| Customization Options | Extensive (printing, color, sizing, features) | Minimal (basic color choices, no custom prints) |

| Design & Fit | Ergonomic, "Large Space" for layering, adjustable features | Basic, often restrictive, limited adjustability |

This comparison highlights the significant value proposition of our specialized rainwear for B2B clients who prioritize performance, safety, and brand integrity.

Application Case Studies & Client Experience

Our advanced children's rainwear solutions have been successfully implemented by various organizations, demonstrating tangible benefits.

Case Study 1: "Green Horizons" Outdoor School Program

Client: Green Horizons Outdoor Education, a network of forest schools across the UK.

Challenge: Green Horizons needed highly durable, waterproof, and breathable raincoats for children aged 4-12, suitable for daily outdoor sessions in all weather conditions. Previous raincoats failed quickly, leading to discomfort and frequent replacements.

Solution: We supplied 500 units of the high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat, customized with their distinctive leaf logo and in vibrant, high-visibility colors. Key features included reinforced elbows, adjustable storm hoods, and PFC-free DWR.

Outcome: After two academic years, the raincoats demonstrated exceptional longevity and performance. Feedback from educators reported significantly fewer instances of children feeling cold or wet, contributing to improved engagement and a more positive learning experience. The robust construction and easy maintenance reduced replacement costs by over 40% annually.

Case Study 2: "PlayVentures" Kids' Gear Retailer

Client: PlayVentures, a rapidly growing online retailer specializing in premium children's outdoor equipment.

Challenge: PlayVentures sought to introduce a proprietary line of technical rainwear that could compete with established outdoor brands, emphasizing eco-friendly materials and high performance for adventurous families.

Solution: We collaborated to develop a private-label version of the raincoat, utilizing recycled polyester fabrics and featuring a unique internal moisture-wicking lining. The raincoats were custom printed with PlayVentures' branding and designed with specific adventure-oriented features like extended back hems for bike riding.

Outcome: The product line launched successfully, quickly becoming a top-seller due to its perceived quality and performance metrics. Customer reviews frequently highlighted the coat's waterproofing, breathability, and durable construction. PlayVentures reported a 25% increase in their children's apparel segment revenue within the first year of launch.

Authoritativeness, Certifications, and Quality Assurance

Our commitment to quality, safety, and ethical manufacturing is underpinned by rigorous certifications and established industry partnerships.

- ISO 9001:2015 Certified Manufacturing: Our production facilities adhere to the international standard for quality management systems, ensuring consistent product quality and continuous improvement.

- OEKO-TEX Standard 100 Certified Materials: All primary fabrics and components are tested for harmful substances, guaranteeing that the end product is safe for children's skin and health. This is particularly crucial for children's wear.

- REACH Compliance: We ensure all materials and manufacturing processes comply with the European Union's REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) regulation, further assuring chemical safety.

- Years of Service & Expertise: With over 15 years in technical apparel manufacturing, our team possesses deep expertise in fabric technology, garment engineering, and B2B supply chain management.

- Strategic Partnerships: We collaborate with leading fabric mills and component suppliers (e.g., YKK for zippers, reputable membrane manufacturers) to integrate best-in-class materials into our products.

- Independent Lab Testing: Beyond internal QA, our products undergo periodic validation by independent, accredited laboratories to confirm performance metrics like hydrostatic head, MVTR, and tensile strength.

Trustworthiness and Support Information

Frequently Asked Questions (FAQ)

Q: What is the minimum order quantity (MOQ) for custom printed raincoats?

A: Our standard MOQ for custom printed orders typically ranges from 300 to 500 units, depending on the complexity of customization and fabric availability. Please contact our sales team for specific project requirements.

Q: How do you ensure the safety of the materials used in the children's raincoats?

A: All our materials are sourced from OEKO-TEX Standard 100 certified suppliers and comply with REACH regulations, ensuring they are free from harmful substances and safe for children.

Q: Can we request samples before placing a bulk order?

A: Yes, we offer pre-production samples for quality assurance and design verification. Sample lead times and costs will be discussed during the initial consultation.

Lead Time & Fulfillment

Standard production lead time for a bulk order (e.g., 1,000 units) is typically 45-60 days from final sample approval and deposit receipt. This includes material sourcing, production, quality control, and packaging. Expedited options may be available depending on capacity. Shipping logistics are tailored to client needs, including FOB, CIF, or DDP terms.

Warranty Commitments

We stand behind the quality of our products. All high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat units come with a 1-year warranty covering manufacturing defects under normal use. This warranty reflects our confidence in our stringent quality control processes and the durability of our materials and construction.

Customer Support

Our dedicated B2B customer support team is available to assist with all inquiries, from initial design consultation to post-delivery support. We provide comprehensive technical advice, order tracking, and after-sales service. Contact us via email at sales@mayraincoat.com or call our dedicated support line during business hours.

Conclusion

The demand for specialized, high-performance children's outdoor apparel continues to grow, driven by an increased emphasis on safety, durability, and environmental responsibility. The high quality Outdoor children waterproof raincoat windproof custom printed large space rain coat represents the pinnacle of engineering in this segment, offering a superior combination of technical features, robust construction, and extensive customization options. For B2B partners, this product not only meets but exceeds the complex requirements of diverse application scenarios, providing a reliable, long-lasting, and brand-enhancing solution. Our commitment to quality, backed by rigorous certifications and a comprehensive support framework, ensures that choosing our rainwear is a strategic investment in performance and trust.

References

- ISO. (2020). ISO 9001:2015 – Quality management systems – Requirements. International Organization for Standardization.

- OEKO-TEX®. (2023). STANDARD 100 by OEKO-TEX®. Retrieved from oeko-tex.com.

- European Chemicals Agency (ECHA). (2023). REACH – Registration, Evaluation, Authorisation and Restriction of Chemicals. Retrieved from echa.europa.eu.

- ASTM International. (2023). ASTM D737 - Standard Test Method for Air Permeability of Textile Fabrics. Retrieved from astm.org.

- British Standards Institution (BSI). (2023). BS EN 14682:2014 – Safety of children's clothing – Cords and drawstrings on children's clothing – Specifications. Retrieved from bsigroup.com.

-

Stylish & Durable Lined Rain Coat Womens for Every Season | MayRainCoat

NewsNov.23,2025

-

Discover the Versatile and Sustainable Lilac Raincoat – Style Meets Innovation

NewsNov.23,2025

-

Lightweight Waterproof Coat: Durable, Comfortable, and Eco-Friendly Protection Worldwide

NewsNov.22,2025

-

Lightweight Raincoat – Ultimate Guide to Durable, Packable Rain Protection

NewsNov.21,2025

-

Lightweight Rain Poncho – Durable, Portable Weather Protection for Every Need

NewsNov.20,2025

-

Lightweight Poncho Rain: Durable, Portable Rain Protection for Any Situation

NewsNov.20,2025