rainwears@163.com may@may-rain.com

rainwears@163.com may@may-rain.com Mon to Friday: 8.00 am - 7.00 pm

Mon to Friday: 8.00 am - 7.00 pm

Jan . 09, 2025 10:39

Back to list

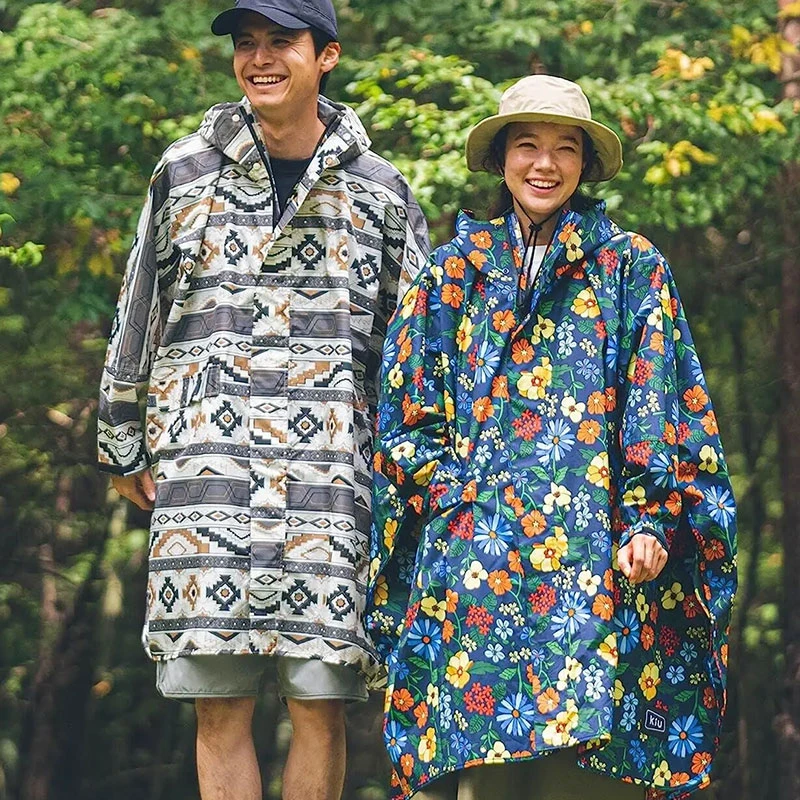

Polyester long raincoat with waterproof zipper windproof outdoor rain coat for adult button cuff

In the detailed and meticulously structured world of raincoat manufacturing, one discovers an intricate tapestry of innovation driven by experience, expertise, authoritativeness, and trustworthiness — the cornerstones for producing high-quality rainwear that stands resilient in the face of nature's unpredictable temperament.

The expertise employed doesn't stop at textiles but extends into technology, with manufacturers adopting cutting-edge sewing techniques such as ultrasonic welding. This technique effectively binds seams without needle perforations, significantly enhancing water resistance which is a testament to the expertise and innovation coursing through the industry. A hallmark of esteemed manufacturers is the collaboration with industry experts and fashion designers, ensuring that every product line not only fulfills functional necessities but also adheres to fashion and durability standards. These collaborations further demonstrate the authoritative status these manufacturers hold, pushing the boundaries of traditional raincoat designs into new, uncharted territories. In essence, the true power of a raincoat manufacturer lies in their unyielding commitment to experience-driven advancement and consumer-centric philosophies. By fostering a culture of expertise and innovation, combined with transparent and sustainable practices, these manufacturers carve a niche of reliability and leadership, providing products that not only meet but exceed consumer expectations. Every raincoat that rolls off the production line echoes a heritage of experience and a forward-thinking vision. By championing quality and authenticity, these manufacturers craft rainwear that is an amalgamation of resilience, style, and trust — the quintessential gear for weather warriors across the globe.

The expertise employed doesn't stop at textiles but extends into technology, with manufacturers adopting cutting-edge sewing techniques such as ultrasonic welding. This technique effectively binds seams without needle perforations, significantly enhancing water resistance which is a testament to the expertise and innovation coursing through the industry. A hallmark of esteemed manufacturers is the collaboration with industry experts and fashion designers, ensuring that every product line not only fulfills functional necessities but also adheres to fashion and durability standards. These collaborations further demonstrate the authoritative status these manufacturers hold, pushing the boundaries of traditional raincoat designs into new, uncharted territories. In essence, the true power of a raincoat manufacturer lies in their unyielding commitment to experience-driven advancement and consumer-centric philosophies. By fostering a culture of expertise and innovation, combined with transparent and sustainable practices, these manufacturers carve a niche of reliability and leadership, providing products that not only meet but exceed consumer expectations. Every raincoat that rolls off the production line echoes a heritage of experience and a forward-thinking vision. By championing quality and authenticity, these manufacturers craft rainwear that is an amalgamation of resilience, style, and trust — the quintessential gear for weather warriors across the globe.

Previous:

Latest news

-

Explore Durable and Sustainable Lined Raincoats – Protection Meets Comfort

NewsNov.24,2025

-

Stylish & Durable Lined Rain Coat Womens for Every Season | MayRainCoat

NewsNov.23,2025

-

Discover the Versatile and Sustainable Lilac Raincoat – Style Meets Innovation

NewsNov.23,2025

-

Lightweight Waterproof Coat: Durable, Comfortable, and Eco-Friendly Protection Worldwide

NewsNov.22,2025

-

Lightweight Raincoat – Ultimate Guide to Durable, Packable Rain Protection

NewsNov.21,2025

-

Lightweight Rain Poncho – Durable, Portable Weather Protection for Every Need

NewsNov.20,2025