rainwears@163.com may@may-rain.com

rainwears@163.com may@may-rain.com Mon to Friday: 8.00 am - 7.00 pm

Mon to Friday: 8.00 am - 7.00 pm

Waterproof Women’s Jackets - Breathable & Seam-Sealed

Field Notes on Waterproof Women’s Jackets: What Matters in 2025

If you’re skimming for the essentials, here they are: Waterproof Women’s Jackets have matured from “rain shell” to multi-role gear you can wear from subway to summit. I’ve visited factories in Shijiazhuang (Origin: Rm.1816 No. 44 Jianshe north street, Shijiazhuang, China) and watched lamination lines run at dawn. The best pieces now balance hydrostatic head, breathability, and soft hand-feel—without that crinkly poncho vibe.

Trends I’m Seeing

- PFC-free DWR finishes and bluesign/OEKO-TEX materials—finally mainstream.

- Urban-outdoor hybrids: clean silhouettes, trail-ready guts.

- Lighter 2.5L shells for carry-everywhere; 3L for mountain days.

- Inclusive sizing and modular hoods—honestly overdue.

Real-World Spec Snapshot

Below is a typical configuration I’ve seen on modern Waterproof Women’s Jackets in the mid/high tier. Your mileage—literally—may vary.

| Shell Fabric | 100% polyester or nylon, 70–120 g/m², ripstop or plain weave |

| Construction | 2.5L (commute/travel) or 3L (mountain) |

| Waterproof Rating | ≈10,000–20,000 mm (ISO 811 / AATCC 127) [lab]; real-world varies |

| Breathability | 8,000–15,000 g/m²/24h (JIS L 1099 B1/B2) |

| Seam Taping | Full, 13–20 mm tape; critical seams double-taped |

| DWR Finish | PFC-free C0; spray test ≈ 80–90 after 5 washes (AATCC 22) |

| Weight | Around 260–420 g (M) |

| Service Life | 3–5 years with periodic DWR renewal; heavy use may shorten |

| Certifications | EN 343, OEKO-TEX STANDARD 100, bluesign-approved components |

How They’re Built (Quick Process Flow)

- Material selection: yarn count, membrane (PU/PTFE/PE), lining.

- Lamination or coating: 2.5L print or 3L tricot backer.

- Cutting & bonding: pattern nesting; seam taping at controlled temp/pressure.

- DWR application and curing; wash-down to assess spray rating.

- Testing: ISO 811/AATCC 127 (hydrostatic), AATCC 22/35 (spray/penetration), EN 343 for classing.

- QC & packaging: needle detection (for uniforms), barcode traceability.

Use Cases, Quickly

- Daily commute: packable 2.5L, hand pockets, reflective trims.

- Trail & travel: pit zips, helmet-compatible hood, dropped hem.

- Workwear/uniform: EN 343 compliance, logos via heat-transfer.

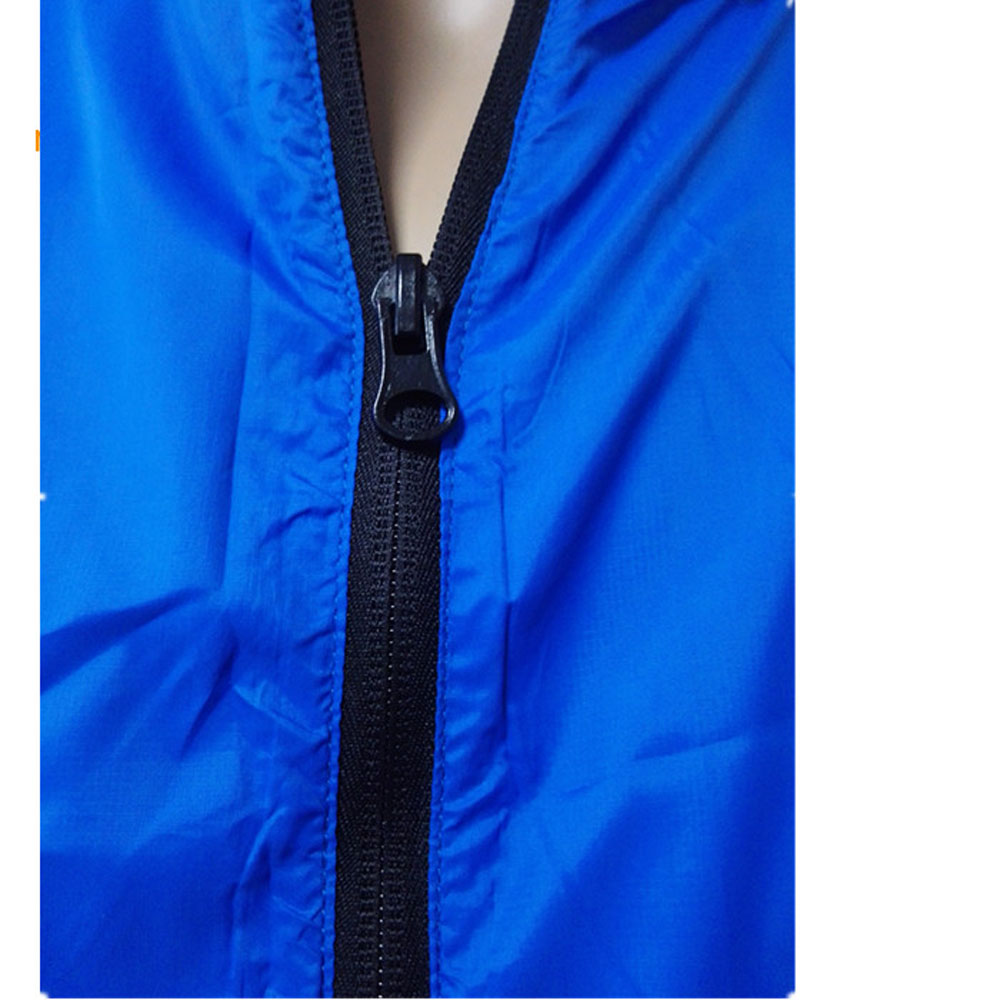

- Coastal weather: 3L shell, YKK AquaGuard zips, stiffer brim.

Vendor Snapshot & Customization

The listed product is a “waterproof jackets women’s rain coat jacket custom rain jacket.” Custom runs typically allow fabric, color, and trim tweaks—plus branding. Here’s a simple, real-world style comparison I keep in my notes:

| Vendor Type | MOQ | Lead Time | Certs | Notes |

|---|---|---|---|---|

| Mayrain (Shijiazhuang) | ≈300–800 pcs | 30–45 days | EN 343, OEKO-TEX (components) | Strong custom options; value pricing |

| Premium Outdoor Brand | N/A (retail) | In-stock | Broad, including bluesign | Higher price; proven field testing |

| Fast-Fashion Importer | 1,000+ pcs | 20–35 days | Limited | Lowest cost; specs vary widely |

Mini Case Notes

City-to-coast commuter: After switching to a 2.5L shell with pit-zips, a buyer reported fewer clammy shoulders and better packability; spray rating held ≈90 after five washes.

Logistics team uniform: A 3L EN 343 set with reflective piping cut sick-day weather disruptions in a wet quarter (anecdotal, but echoed by supervisors).

Testing & Standards (why you should care)

Look for hydrostatic ≥10,000 mm (ISO 811/AATCC 127), spray test ≥80 (AATCC 22), and EN 343 Class 3:3 for heavy rain. Many customers say they feel the difference on windy platforms at 6 a.m., which, frankly, is the truest test.

References: [1] ISO 811:2018 (Hydrostatic pressure). [2] AATCC TM127 & TM22. [3] EN 343:2019 Protective clothing. [4] OEKO-TEX STANDARD 100 guidelines.

-

Stylish & Durable Lined Rain Coat Womens for Every Season | MayRainCoat

NewsNov.23,2025

-

Discover the Versatile and Sustainable Lilac Raincoat – Style Meets Innovation

NewsNov.23,2025

-

Lightweight Waterproof Coat: Durable, Comfortable, and Eco-Friendly Protection Worldwide

NewsNov.22,2025

-

Lightweight Raincoat – Ultimate Guide to Durable, Packable Rain Protection

NewsNov.21,2025

-

Lightweight Rain Poncho – Durable, Portable Weather Protection for Every Need

NewsNov.20,2025

-

Lightweight Poncho Rain: Durable, Portable Rain Protection for Any Situation

NewsNov.20,2025