Links:

-

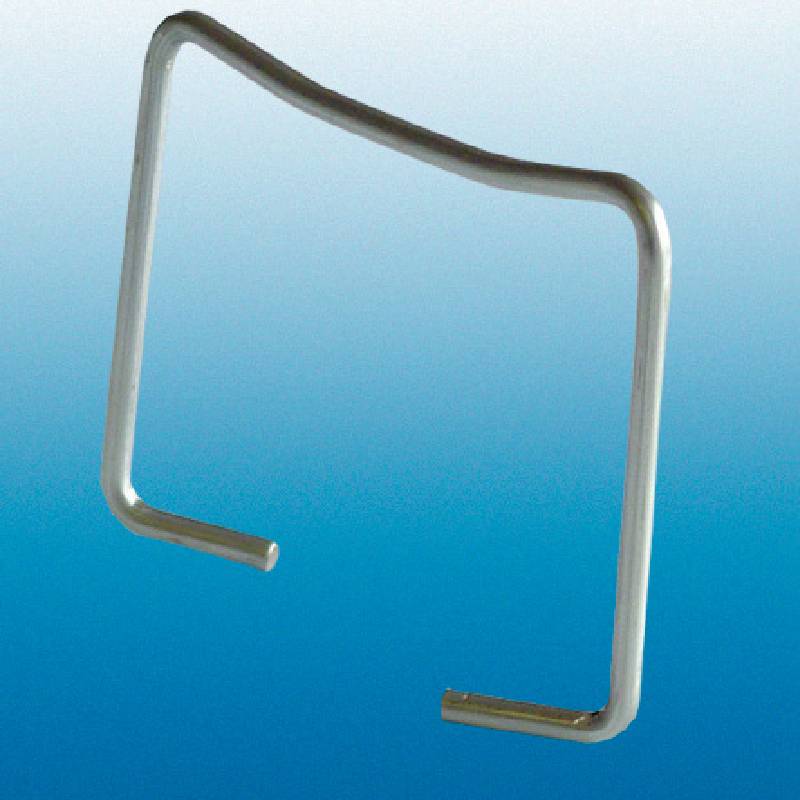

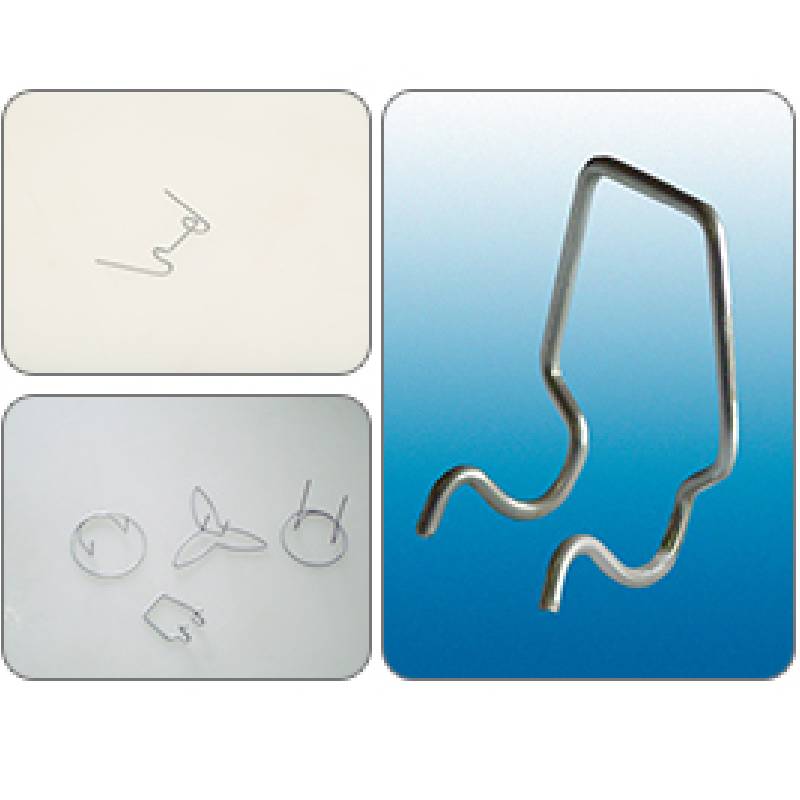

The process of galvanizing involves coating the wall ties with a layer of zinc, which provides protection against corrosion and rust. This ensures that the wall ties have a long lifespan and can withstand harsh weather conditions without deteriorating. The galvanized coating also provides a smooth surface, making it easier for mortar to adhere to the ties during construction. Another important function of rotary springs is to act as a shock absorber or vibration dampener in a system. By absorbing and dissipating energy from sudden impacts or fluctuations, rotary springs help to reduce wear and tear on other components and improve the overall performance and longevity of the system

rotary springs. In conclusion, overhead poultry netting is a multifaceted innovation that has revolutionized poultry farming. It offers protection, promotes health and productivity, simplifies management tasks, enhances biosecurity, and supports environmentally friendly practices. As we continue to seek out advancements in agriculture, the implementation of such solutions ensures that the future of farming is not only profitable but also humane and sustainable. Helical Extension Springs A Comprehensive Guide The Artistry of Coated Floral Wire A Versatile Tool for Creative Expression The decision to purchase bulk tomato stakes not only enhances the health and productivity of your tomato plants but also simplifies the planting process. With a ready supply at hand, you can quickly and efficiently stake each plant as needed, allowing you to focus on other aspects of garden maintenance and care. Overall, wholesale cattle fencing is a cost-effective and reliable solution for farmers looking to secure their livestock. With its affordability, ease of installation, and versatility, wholesale fencing offers a practical way to protect cattle while also staying within budget. By investing in high-quality fencing materials, farmers can ensure the safety and well-being of their livestock for years to come. One of the key advantages of using iron wire is its versatility. It can be bent, twisted, and shaped into virtually any form, making it ideal for a wide range of applications. Whether you're looking to create a delicate piece of jewelry or a sturdy piece of functional hardware, iron wire has the strength and durability to get the job done. In conclusion, coated floral wire is more than just a tool; it is a medium of artistic expression. Its combination of strength, flexibility, and aesthetic appeal makes it a favorite among artists, florists, and hobbyists alike. Whether you're a professional florist creating grand wedding bouquets or a DIY enthusiast crafting a personalized gift, coated floral wire is a versatile ally in your creative journey, ready to transform your ideas into tangible, beautiful works of art. Another advantage of this product is its ease of installation

extra strong chicken wire. Unlike some other types of fencing, extra strong chicken wire is quick and easy to install. You can use it to create custom-sized fences or screens, and it can be attached to wooden posts or metal frames with ease. This makes it a great DIY project for homeowners who want to save money while still enjoying the benefits of a secure and attractive garden. One of the key benefits of large metal stakes is their strength and durability. Made from high-quality materials such as steel or aluminum, these stakes can withstand heavy loads and extreme weather conditions without bending or breaking. This makes them a reliable option for projects that require long-term stability and security. Moreover, wire mesh garden fences offer excellent visibility, allowing you to enjoy the beauty of your garden from within while deterring potential intruders, be it curious pets or unwelcome wildlife. They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments

extra strong chicken wire. Unlike some other types of fencing, extra strong chicken wire is quick and easy to install. You can use it to create custom-sized fences or screens, and it can be attached to wooden posts or metal frames with ease. This makes it a great DIY project for homeowners who want to save money while still enjoying the benefits of a secure and attractive garden. One of the key benefits of large metal stakes is their strength and durability. Made from high-quality materials such as steel or aluminum, these stakes can withstand heavy loads and extreme weather conditions without bending or breaking. This makes them a reliable option for projects that require long-term stability and security. Moreover, wire mesh garden fences offer excellent visibility, allowing you to enjoy the beauty of your garden from within while deterring potential intruders, be it curious pets or unwelcome wildlife. They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments

They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments They are also relatively low maintenance, requiring only occasional cleaning and rust prevention treatments wire mesh garden fence. 2. Stainless steel This material is resistant to corrosion and has excellent fatigue resistance. It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries

wire mesh garden fence. 2. Stainless steel This material is resistant to corrosion and has excellent fatigue resistance. It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries

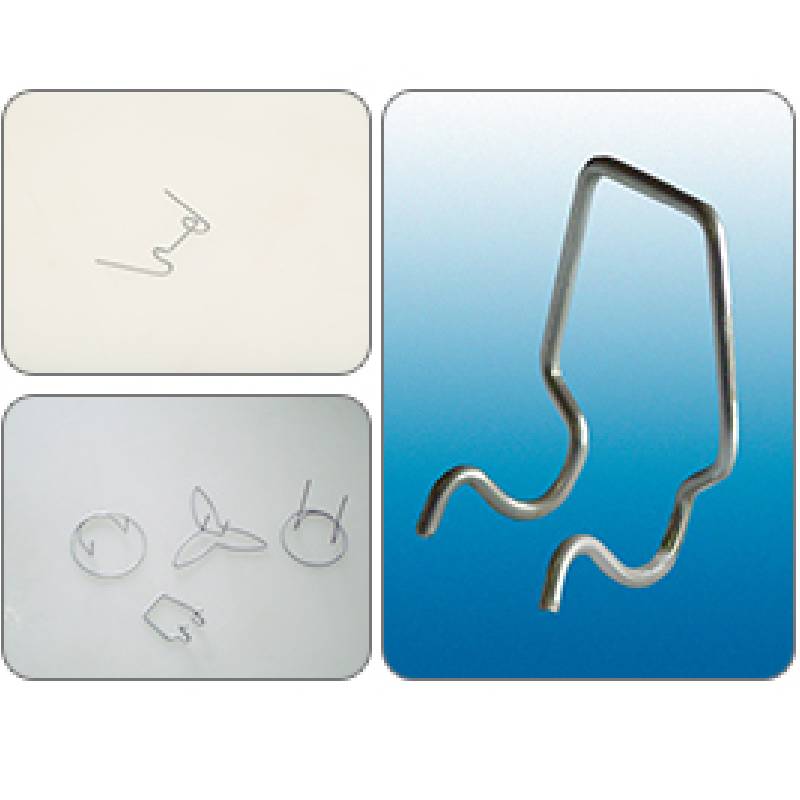

It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries It is commonly used in applications where high reliability and cleanliness are required, such as in the food and pharmaceutical industries flat wire spring manufacturers. When buying aluminum craft wire wholesale, it is important to find a reputable supplier that offers high-quality products. Look for suppliers that have a good reputation for their materials and customer service. You may also want to consider factors such as shipping times, return policies, and customer reviews when choosing a wholesale supplier. 3. Ensure that the walls are properly prepared before installing the ties, including cleaning the surfaces and removing any debris or obstructions. In addition to its primary function, 3/8 rib lath also contributes to insulation and soundproofing. Its metal composition acts as a barrier, preventing heat transfer and reducing noise infiltration, thereby enhancing the overall energy efficiency and acoustic comfort of a building. In the automotive industry, tension springs with hooks are used in engine valves, seat belts, and suspension systems, ensuring smooth operation and safety. In the aerospace sector, they find application in landing gear, control surfaces, and cabin equipment. Manufacturing plants employ them in assembly lines and conveyor systems, while construction relies on them in elevator systems and heavy machinery.

flat wire spring manufacturers. When buying aluminum craft wire wholesale, it is important to find a reputable supplier that offers high-quality products. Look for suppliers that have a good reputation for their materials and customer service. You may also want to consider factors such as shipping times, return policies, and customer reviews when choosing a wholesale supplier. 3. Ensure that the walls are properly prepared before installing the ties, including cleaning the surfaces and removing any debris or obstructions. In addition to its primary function, 3/8 rib lath also contributes to insulation and soundproofing. Its metal composition acts as a barrier, preventing heat transfer and reducing noise infiltration, thereby enhancing the overall energy efficiency and acoustic comfort of a building. In the automotive industry, tension springs with hooks are used in engine valves, seat belts, and suspension systems, ensuring smooth operation and safety. In the aerospace sector, they find application in landing gear, control surfaces, and cabin equipment. Manufacturing plants employ them in assembly lines and conveyor systems, while construction relies on them in elevator systems and heavy machinery. One of the key benefits of adjustable compression springs is their versatility. By simply turning a screw or nut, the spring can be compressed or decompressed to adjust the amount of force it exerts. This makes them ideal for applications where precise control over compression force is required, such as in automotive suspension systems, industrial machinery, and medical devices.

In addition to their structural role, cavity wall ties also serve as a barrier against water penetration. The small gaps between the ties allow water to drain out, rather than seeping into the building's interior. This helps prevent dampness, mold growth, and other moisture-related problems that can compromise the health and comfort of occupants.

1. Prepare the work area Ensure that the area where the cavity wall ties will be installed is clean and free of debris. Remove any loose mortar or debris from the joints between the inner and outer walls. Proper maintenance is crucial for extending the life of 5-inch coil springs. Regularly inspecting the springs for signs of wear, corrosion, or damage can help prevent premature failure. Cleaning the springs with a mild detergent and water can remove dirt and debris that may affect their performance. Lubricating the springs can reduce friction and wear, especially in high-load applications. Finally, storing the springs in a dry, clean environment can prevent rust and corrosion. Once the baskets were ready, the artists climbed the tree and attached them to the branches. It was a meticulous process, requiring patience and skill. But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes

But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes

But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes metal basket tree. Moreover, plant support also enhances air circulation around the plant, reducing humidity and the likelihood of fungal diseases. Adequate spacing between plants and their support structures allows air to flow freely, promoting healthier foliage and preventing moisture buildup that can lead to rotting. Our company specializes in the production of high-quality tension springs that meet the most stringent industry standards. We understand that every application has unique requirements, which is why we offer customized solutions to meet your specific needs. Our team of experienced engineers works closely with clients to understand their requirements and design springs that provide optimal performance. One of the standout features of the steel wire grid panel is its exceptional strength and durability. Constructed from high-quality steel wires that are securely woven together, these panels can withstand heavy loads and resist corrosion, ensuring long-lasting performance in even the most demanding environments. Whether you need to install a partition wall or create a durable shelving system, the steel wire grid panel will provide the necessary support and stability. Despite their functional importance, masonry ties often go unnoticed, hidden within the walls they strengthen

metal basket tree. Moreover, plant support also enhances air circulation around the plant, reducing humidity and the likelihood of fungal diseases. Adequate spacing between plants and their support structures allows air to flow freely, promoting healthier foliage and preventing moisture buildup that can lead to rotting. Our company specializes in the production of high-quality tension springs that meet the most stringent industry standards. We understand that every application has unique requirements, which is why we offer customized solutions to meet your specific needs. Our team of experienced engineers works closely with clients to understand their requirements and design springs that provide optimal performance. One of the standout features of the steel wire grid panel is its exceptional strength and durability. Constructed from high-quality steel wires that are securely woven together, these panels can withstand heavy loads and resist corrosion, ensuring long-lasting performance in even the most demanding environments. Whether you need to install a partition wall or create a durable shelving system, the steel wire grid panel will provide the necessary support and stability. Despite their functional importance, masonry ties often go unnoticed, hidden within the walls they strengthen masonry ties. Yet, their presence is a subtle reminder of the evolution of construction techniques and the ongoing dialogue between tradition and modernity. Today, with the push towards sustainable and eco-friendly building practices, there is a renewed interest in exploring new materials and methods while still relying on the fundamental principles that masonry ties represent.

masonry ties. Yet, their presence is a subtle reminder of the evolution of construction techniques and the ongoing dialogue between tradition and modernity. Today, with the push towards sustainable and eco-friendly building practices, there is a renewed interest in exploring new materials and methods while still relying on the fundamental principles that masonry ties represent. Wall ties for concrete are critical for stabilizing concrete walls and connecting them to other structural elements. These ties prevent the walls from bowing or collapsing under pressure. Adjustable brick ties offer flexibility in connecting brickwork to concrete or steel frames, accommodating varying distances between the components. Adjustable brick ties are especially useful in projects where precise alignment is necessary but conditions may vary. Their adaptability ensures a secure bond between different materials, enhancing the overall stability of the structure.

Compression coil springs, as the name suggests, are designed to resist compression force. They are made from coiled metal wires, usually in a cylindrical shape, and when subjected to an external load, they compress and store energy. The unique characteristic of these springs lies in their ability to return to their original shape after the load is removed, a phenomenon known as elastic recovery. The world of cryptocurrency is rapidly evolving, with new technologies and concepts emerging constantly. One such concept that has gained significant attention in recent years is metal staking. Metal staking, which involves locking up a certain amount of cryptocurrency in a smart contract to support the network and earn rewards, is becoming an increasingly popular way for crypto holders to participate in the ecosystem. In this article, we will explore the concept of metal staking, its benefits, and how it is changing the landscape of the cryptocurrency world. Exploring Different Types of Field Fences Barriers and Boundaries in Agriculture Moreover, these manufacturers adhere to international quality standards, ensuring durability, strength, and precision in their products. They invest heavily in research and development to introduce innovative production techniques, thereby enhancing efficiency and reducing costs. This commitment to quality and innovation has led to China becoming a major exporter of wire mesh worldwide. Metal formwork is a popular choice for construction projects due to its durability and efficiency. One type of metal formwork that has gained popularity in recent years is permanent metal formwork.The term concrete mesh refers to a steel wire fabric that is specifically engineered for use as a reinforcement material in concrete pours. It is typically made from high-strength carbon steel wires, woven or welded together to form a square or rectangular pattern. This mesh serves as a skeleton within the concrete, distributing loads evenly and preventing cracks from propagating.

Fiberglass reinforcement is a lightweight and non-corrosive option that is easy to handle and install. It is an excellent choice for projects where weight is a concern or where there is a need for non-metallic reinforcement.

In addition to its durability and flexibility, thick craft wire is also available in a wide range of colors and finishes

When shopping for chicken wire for sale, there are a few things to consider

When shopping for chicken wire for sale, there are a few things to consider chicken wire for sale. The gauge, or thickness, of the wire will determine its strength and durability. A higher gauge number indicates a thinner wire, while a lower gauge number indicates a thicker wire. For most applications, a gauge of 20 or 22 is sufficient, but if you need extra strength, you may want to consider a lower gauge. The use of timber frame wall ties offers several advantages. Firstly, they contribute to the overall efficiency of the construction process due to their simplicity and ease of installation. They can be quickly fixed into place during the assembly of the timber frame, reducing on-site time and labor costs. Moreover, their lightweight nature aligns with the sustainable philosophy of timber frame construction, as it minimizes the environmental impact through reduced transportation emissions. The material selection for a 2-inch compression spring is critical. Common materials include steel, stainless steel, chrome silicon, and titanium, each with its own set of advantages. Steel offers high strength and low cost, while stainless steel provides corrosion resistance. Chrome silicon offers excellent fatigue life, and titanium, though more expensive, is lightweight and highly resistant to corrosion. Swing Extension is a set of components that enhances the Swing library by providing additional controls and functionalities. These extensions range from advanced data tables to sophisticated charting components, which can significantly improve the user experience in desktop applications. However, integrating these components into an application architecture can be challenging, especially when dealing with dependencies and configurations. Galvanized welded wire mesh, a widely utilized material in various industries, is a testament to the harmonious blend of functionality and durability. This innovative product is essentially a grid-like structure made from steel wires that have been electrically or thermally bonded together at intersections, and subsequently coated with zinc for enhanced corrosion resistance. Furthermore, PVC galvanized wire is easy to work with and can be easily cut, bent, and shaped to fit different project requirements

chicken wire for sale. The gauge, or thickness, of the wire will determine its strength and durability. A higher gauge number indicates a thinner wire, while a lower gauge number indicates a thicker wire. For most applications, a gauge of 20 or 22 is sufficient, but if you need extra strength, you may want to consider a lower gauge. The use of timber frame wall ties offers several advantages. Firstly, they contribute to the overall efficiency of the construction process due to their simplicity and ease of installation. They can be quickly fixed into place during the assembly of the timber frame, reducing on-site time and labor costs. Moreover, their lightweight nature aligns with the sustainable philosophy of timber frame construction, as it minimizes the environmental impact through reduced transportation emissions. The material selection for a 2-inch compression spring is critical. Common materials include steel, stainless steel, chrome silicon, and titanium, each with its own set of advantages. Steel offers high strength and low cost, while stainless steel provides corrosion resistance. Chrome silicon offers excellent fatigue life, and titanium, though more expensive, is lightweight and highly resistant to corrosion. Swing Extension is a set of components that enhances the Swing library by providing additional controls and functionalities. These extensions range from advanced data tables to sophisticated charting components, which can significantly improve the user experience in desktop applications. However, integrating these components into an application architecture can be challenging, especially when dealing with dependencies and configurations. Galvanized welded wire mesh, a widely utilized material in various industries, is a testament to the harmonious blend of functionality and durability. This innovative product is essentially a grid-like structure made from steel wires that have been electrically or thermally bonded together at intersections, and subsequently coated with zinc for enhanced corrosion resistance. Furthermore, PVC galvanized wire is easy to work with and can be easily cut, bent, and shaped to fit different project requirements

pvc galvanized wire. Its flexibility and versatility make it suitable for a variety of applications, from simple DIY projects to large-scale industrial installations. The PVC coating also provides a smooth surface that is easy to handle and does not snag or cause injuries during installation. One of the primary advantages of black coated wire mesh is its excellent corrosion resistance. The coating not only provides a protective layer against rust and corrosion but also enhances the overall durability of the material. This makes it suitable for use in harsh environments where exposure to moisture, salt, and other corrosive substances is common. However, over time, brick ties can degrade due to factors like corrosion, especially if they are not properly protected. This can lead to serious structural issues, necessitating regular inspections and, if necessary, replacement. Brick ties, an often overlooked yet essential component in construction, play a pivotal role in the stability and integrity of stud walls when built with brick facades. These small, yet mighty connectors serve as the unseen glue that binds the brickwork to the structural frame, ensuring safety, durability, and compliance with building regulations. Notably, copper craft wire also plays a significant role in eco-friendly art. As a recyclable material, it aligns with the growing awareness of sustainability in the arts. Many artists now use reclaimed copper wire, giving old electrical wires and plumbing fixtures a new lease on life as beautiful, functional, or purely aesthetic creations. 7. Customer Service Look for manufacturers that provide excellent customer service and support throughout the entire process, from initial inquiry to installation and post-sales service. A manufacturer that values customer satisfaction will ensure a positive experience for you as a buyer. One of the primary advantages of the white wire grid is its adaptability. Whether it is used in a retail setting to hang products or in a home to display artwork and photographs, the grid offers a blank canvas for personalization. Its color, being white, seamlessly integrates with various color schemes without dominating the visual landscape. This allows the items displayed on the grid to take center stage, enhancing their visibility and importance within the space. The selection of the right type of steel-to-masonry tie is crucial. Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie

Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie

Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie Factors like the thickness of the masonry, the expected loads, and the environmental conditions all play a part in determining the appropriate tie steel to masonry ties. For instance, in areas prone to harsh weather or earthquakes, more robust ties with higher tensile strength would be necessary.

steel to masonry ties. For instance, in areas prone to harsh weather or earthquakes, more robust ties with higher tensile strength would be necessary.