Links:

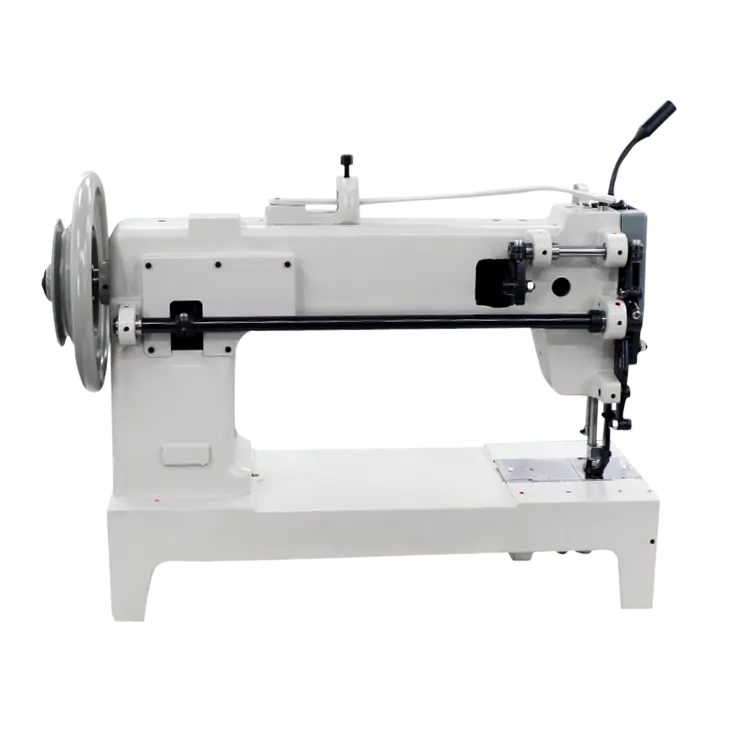

What is a Long Arm Zig Zag Sewing Machine?

In conclusion, upholstery stitching machines are vital in the evolution of the upholstery industry. They combine speed, accuracy, and versatility with the ability to cater to diverse needs, making them indispensable to manufacturers in furniture and automotive sectors. As technology continues to advance, the role of these machines will only expand, allowing for greater creativity, sustainability, and efficiency in upholstery production. Thus, investing in the right upholstery stitching machine is an investment in a company’s ability to meet modern consumer demands while maintaining high-quality standards.

One of the main benefits of using a beginner leather sewing machine is its specialized features. These machines are equipped with heavy-duty needles and presser feet that can easily penetrate through tough leather materials. They also have powerful motors that can handle the extra strain of sewing through multiple layers of leather. Additionally, beginner leather sewing machines often come with adjustable stitch length and tension settings, making it easier to achieve professional-looking results.

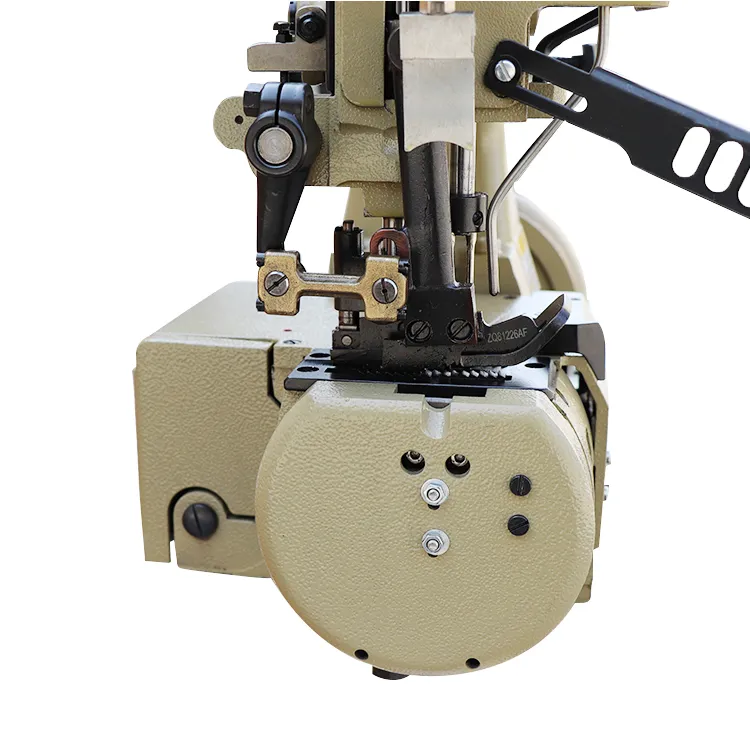

The presser foot is an essential part of a sewing machine that holds the fabric in place while it is being fed through the machine during sewing. Choosing the right presser foot is crucial for achieving the desired stitch quality, especially when working with zigzag stitches. A zigzag presser foot is specifically designed to accommodate the width and depth of the zigzag pattern, allowing for smooth and even stitching.

The design of the double needle sewing machine has evolved significantly since its inception. Originally developed to enhance sewing efficiency, modern double needle machines incorporate advanced technology, including electronic controls and computerized features. These enhancements facilitate precise stitching and reduce the likelihood of human error, thus improving overall productivity. The machine typically consists of two needles, two threads, and a single feed mechanism, which work in unison to create uniform and durable seams.

Final Thoughts

Applications Across Industries

When shopping for a shuttle hook, it is helpful to consider the specific needs of your sewing projects. Different types of projects may require different types of shuttle hooks, so it is important to choose a hook that is compatible with your sewing machine and suitable for the types of stitches you want to create. This can help ensure that you get the best results from your sewing projects while also maximizing the value of your investment in a shuttle hook.

- Environmental Benefits PP bags are recyclable, and their production can be optimized to reduce waste, contributing to more sustainable practices within the industry.

- Thread Weight Thread weight is crucial in determining the thickness and strength of your seams. Typically, for heavy-duty projects, a thread weight of at least 40 or 30 will suffice, but thicker threads are available for more demanding applications.

1. Speed and Efficiency One of the most significant advantages of industrial sewing machines is their speed. While a standard home sewing machine might sew at a rate of 600 stitches per minute, an industrial machine can operate at speeds exceeding 1500 stitches per minute. This increased efficiency is invaluable for those who sew frequently or produce items in larger quantities.

Before diving into pricing, it's important to understand why one might choose an overlock machine with a table

. The table provides a stable work surface that enhances the sewing experience, allowing for more control and precision when handling larger pieces of fabric. Many belt-driven models have an adjustable workspace size, providing flexibility for various sewing projects.When it comes to sewing leather, choosing the right industrial sewing machine needles is crucial. Leather is a tough and durable material that requires special needles that can penetrate through its thickness without causing damage to the fabric. In this article, we will discuss the importance of using the correct needles for sewing leather and provide some tips on how to choose the best ones for your project. The price of an industrial zigzag sewing machine can vary depending on the brand, model, features, and capabilities. Typically, a high-quality industrial zigzag sewing machine can cost anywhere from $1,000 to $10,000 or more. It is important to shop around and compare prices from different manufacturers to ensure you are getting the best value for your money.

Benefits of Overlock Chain Stitch

overlock chain stitch

Additionally, some sewing machine specials come with bonus offers like free sewing classes, accessories, or extended warranties. These add-ons can significantly enhance your sewing experience and help you get the most out of your new machine. For instance, extra presser feet can expand your sewing capabilities—allowing you to experiment with different techniques like quilting, serging, or blind hemming.

Characteristics of Overlock Chain Stitch

Overall, the two needle sewing machine is a valuable tool for any sewer or crafter. Its ability to produce precise, professional-looking stitches quickly and efficiently makes it ideal for a wide range of projects. Whether you are quilting, hemming, or topstitching, the two needle sewing machine will help you achieve beautiful results with ease.

One of the key benefits of automatic button sewing machines is their precision. The machines come equipped with various settings that can be adjusted according to the size and type of button being used. This ensures that each button is securely attached to the fabric without the risk of damaging the garment. The accuracy of these machines also minimizes the likelihood of human error, which can lead to misaligned or poorly attached buttons that may need to be redone.

automatic button sewing machine

Conclusion

How Should I Maintain And Clean A Heavy Duty Sewing Machine?

As fashion and textile trends continue to evolve, the Union Lockstitch Sewing Machine will likely remain a steadfast presence, reflecting the enduring need for innovation in crafting and sewing. For anyone serious about their sewing craft, investing in a Union Lockstitch Sewing Machine may very well be a step toward achieving their creative and professional goals.

Benefits of Needle Feed Technology

needle feed sewing machine

Exploring the Single Needle Edge Cutter Machine A Vital Tool in the Textile Industry

The Versatility and Strength of Heavy Duty Hand Stitching Machines

What is a Chain Stitch Sewing Machine?

Finishing Up

- Use the edge of the presser foot as a guide to maintain a consistent seam allowance, typically 1/4 to 1/2 inch.

Recommended Sewing Machines

The chain lock stitch is not just about aesthetics; it serves a functional purpose too. Its flexibility allows it to adapt to curves and angles with ease, making it ideal for outlining designs or creating text. It's also incredibly strong, able to withstand wear and tear, which is why it's often used in hems, seams, and even in heavy-duty applications like upholstery and banners.

- Type of Material Different machines are tailored for specific materials. Understanding the composition of the bags being used is essential for choosing the appropriate seaming technique.

Limited Stitch Options:

Furthermore, automatic quilting machines can also handle a variety of fabrics and materials with ease. Whether quilting cotton, silk, wool, or even thicker materials like denim, these machines are equipped to handle the job. This versatility allows for endless creative possibilities, as quilters can experiment with different fabrics and textures without worrying about the machine's capabilities.

The primary advantages of utilizing industrial sewing machines for leatherwork include increased production speed, improved stitching accuracy, and the ability to handle thicker materials. The automation and precision of these machines reduce labor costs and minimize material waste, thereby increasing overall profitability for manufacturers.

Finding the right pattern sewing machine for sale can significantly impact your production capabilities. Numerous online and physical retailers offer a wide range of pattern sewing machines, catering to different needs and budgets. When searching for pattern sewing machines for sale, it's crucial to choose a reputable supplier that provides comprehensive after-sales support, including maintenance and repair services.Many manufacturers and authorized dealers offer detailed product descriptions and customer reviews, which can help you make an informed decision. Additionally, some suppliers provide financing options or leasing plans, making it easier to acquire high-quality machines without a substantial upfront investment.

Conclusion

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly

Not only are these machines more affordable than brand-new models, but they are also environmentally friendly Not only are these machines more affordable than brand-new models, but they are also environmentally friendly