Current location:

Links:

-

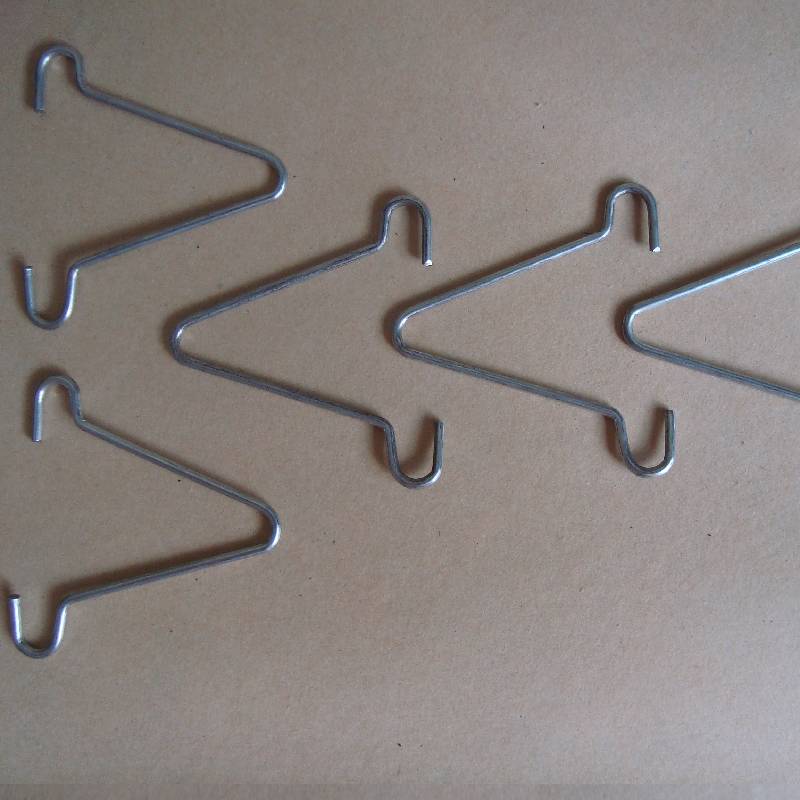

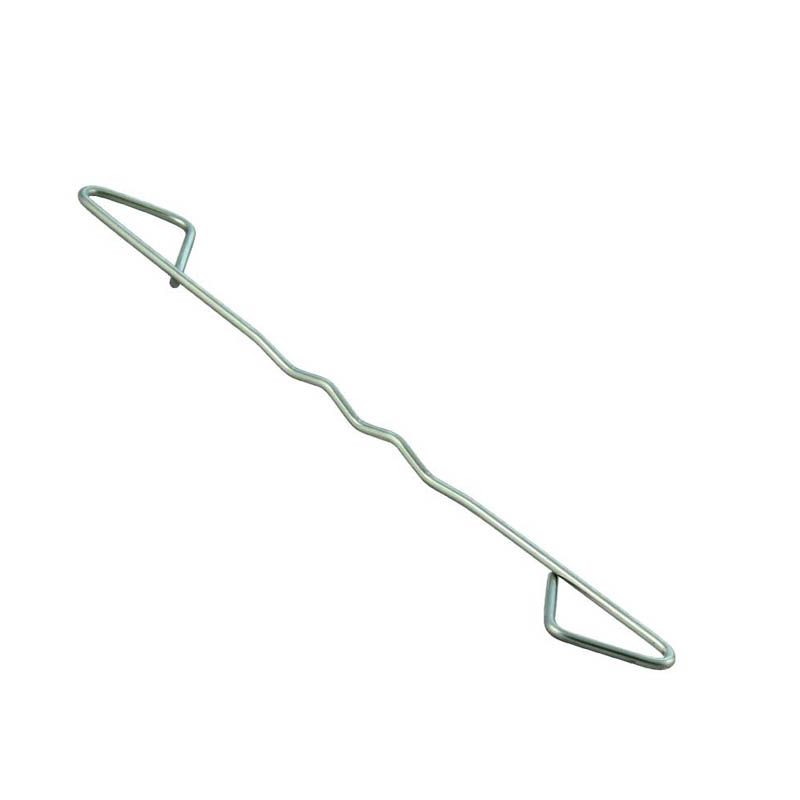

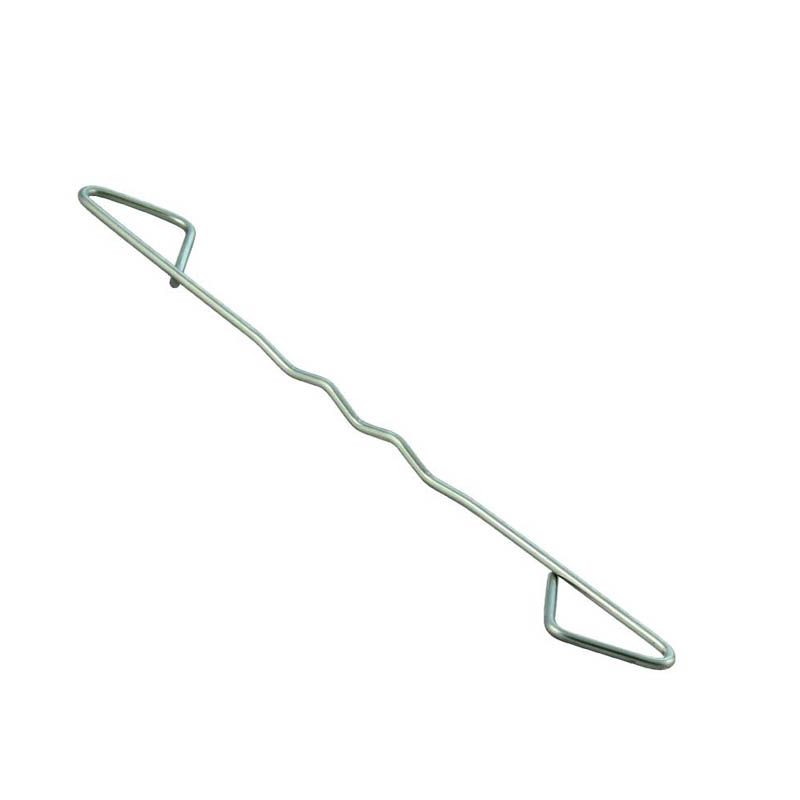

Triangle Wall Ties The Ultimate Solution for Aesthetic and Practical Home Improvement Steel frame wall ties also exhibit excellent durability and resistance to environmental factors. Unlike organic materials prone to rot or rust, steel ties, when properly coated or treated, can shrug off moisture, pests, and fire, ensuring longevity and safety within the building's lifespan. The weld mesh design of these panels offers an additional level of strength and stability. The uniform grid pattern provides excellent visibility, allowing surveillance while maintaining privacy. It also discourages potential intruders, as climbing over the fence becomes challenging due to the closely spaced wires. Moreover, the panels' standard sizes and modular structure make installation quick and straightforward, reducing overall project time and cost. Overall, brick mesh walls offer a combination of durability, versatility, and aesthetic appeal that make them a popular choice for many construction projects. Whether you are building a new home, renovating an existing space, or simply looking to add a touch of elegance to your surroundings, brick mesh walls are a reliable and stylish option to consider.

In addition to their adjustability, these springs also offer other advantages, such as improved control over the spring rate and the ability to customize the spring to meet specific requirements. This makes them a popular choice for engineers and designers who need a flexible and reliable solution for their spring needs.

Mesh products play a critical role in both construction and fencing, offering strength, durability, and versatility. This article explores the various uses of concrete mesh, chain fence, stainless steel mesh, welded wire panels, and wire grid displays in enhancing structural integrity and security.

Another appeal of handcrafted wire jewelry is the versatility of the material itself. Wire comes in various thicknesses, colors, and textures, allowing the maker to experiment with different techniques and designs. From delicate filigree patterns to bold and chunky designs, handcrafted wire jewelry can be as intricate or as simple as the maker desires. This versatility makes wire jewelry making an exciting and rewarding craft for both novice and experienced makers alike

handcraft wire jewelry. Moreover, the 3 8 compression spring is crucial in industrial machinery Bed joint reinforcement typically involves the insertion of steel bars, wires, or mesh into the mortar beds between successive courses of masonry units. The reinforcement material, usually made from high-strength steel, is strategically placed to resist tension forces that could potentially damage the structure. This technique significantly improves the load-bearing capacity, shear resistance, and flexural strength of the masonry wall. Plastering Corner Bead A Crucial Element in Drywall Construction How to Select the Right Welded Mesh Supplier In the world of construction, it's the reinforcement wire mesh that provides the structural integrity necessary to withstand the test of time. This versatile material, made by weaving steel wires together in a crisscross pattern, is used in a variety of applications, from concrete reinforcement for buildings and bridges to fencing and wire meshes for agricultural purposes. In landscaping, large metal stakes are often used to anchor landscape fabric, plastic sheeting, or netting to prevent erosion, control weeds, or protect plants from pests. These stakes are durable enough to withstand outdoor conditions and provide a long-lasting solution for keeping landscaping materials in place

large metal stakes. Additionally, large metal stakes can be used to create borders or edging for flower beds, walkways, or other landscaped areas. Conclusion In the realm of engineering and construction, ensuring the durability and reliability of structures is paramount. One technique that has proven invaluable in achieving this goal is weld mesh reinforcement. This method involves the use of welded wire meshes to strengthen various components, offering a myriad of benefits that enhance both the structural integrity and the overall performance of the built environment. In the realm of masonry construction, the technique of brick tying is a fundamental aspect that ensures the stability and integrity of the entire structure. This intricate process involves the secure attachment of bricks to one another, creating a strong bond that withstands the test of time and various environmental conditions.

To implement HD compression in a Spring-based application, we can follow these steps Hot-dipped galvanized iron wire is a type of metal wire that has undergone a process known as hot-dip galvanization. This process involves coating the iron wire with a layer of zinc to protect it from rust and corrosion. The resulting product is a strong, durable, and long-lasting material that is commonly used in a variety of applications.

The primary advantage of steel mesh panels lies in their composition. Made from steel, they exhibit exceptional strength and resistance to corrosion, ensuring a long lifespan even in harsh environments. This feature makes them ideal for use in construction, where they can be integrated into building structures to provide reinforcement and stability. They also find application in industrial settings as protective barriers, safeguarding machinery and personnel from potential hazards. Another popular option is the electric fence, which delivers a mild electric shock to deter cattle from crossing the boundary. Electric fences are highly effective in containing cattle and are relatively easy to install. However, they require regular monitoring and maintenance to ensure they are functioning correctly

cattle fence. In the realm of artistic expression, aluminum wire floral design stands as a unique and innovative fusion of form and function. This art form, which revolves around crafting lifelike flowers using flexible aluminum wire, has captivated artisans and enthusiasts alike with its delicate beauty and remarkable resilience. One of the key functions of cavity ties is to prevent the movement of the two wall layers relative to each other. This is especially important in areas with high wind or seismic activity, where the walls need to be able to withstand lateral forces without buckling or collapsing. Cavity ties help to distribute these forces evenly across the entire wall structure, ensuring its stability and integrity. Installing Wall Ties A Comprehensive Guide Environmental considerations play a role in the preference for stucco wire as well. The material can be recycled, aligning with the growing trend of sustainable building practices. By choosing a product that minimizes waste and environmental impact, consumers can enjoy the aesthetic benefits of stucco while contributing to green initiatives. Conclusion In addition to these common types of cattle fences, there are also specialized options available for specific purposes. For example, high-tensile wire fences are designed to withstand the pressure exerted by cattle and are ideal for containing large herds. Mesh wire fences, on the other hand, provide a solid barrier that prevents cattle from escaping. 1. Add the necessary dependencies to your project's pom.xml file or build.gradle file, depending on your build system. For example, to use Xuggler, you would need to add the following dependencies In the vast world of mechanical components and engineering, one particular type of spring that often finds its way into various applications is the extension spring. The term 1 8 extension spring might appear cryptic at first, but it holds a significant meaning in the context of spring design and manufacturing. In addition to accommodating thermal movements, expansion wall ties also help to distribute the load of the walls evenly and improve their overall strength. By connecting the walls securely, expansion wall ties help to prevent the walls from bowing or bulging under the weight of the building or external forces. Using 10mm angle beads in jewelry design can elevate a piece from ordinary to exceptional. When strung together, these beads form elegant lines and geometric shapes that catch the eye and invite closer inspection. They are particularly effective in bracelets and necklaces where their angles can be used to create symmetry or to disrupt it for a more dynamic look. In conclusion, the price of 50x50 weld mesh can vary depending on several factors, including the quality of the steel used, the manufacturing process, and the country of origin. It is important to carefully consider these factors when selecting a supplier and purchasing weld mesh for your construction project. By doing so, you can ensure that you are getting a high-quality product that will perform well and provide long-term value for your investment. In recent years, there has been a shift towards more modern, engineered brick ties that offer improved performance and longevity. These advanced ties incorporate features like expansion mechanisms, which allow for some movement due to temperature changes or building settlement, without compromising the structural integrity.

There are many advantages to replacing wall ties.

Annealed Tie Wire

1. Material Composition Stainless steel is more expensive than carbon steel. Affordable tomato cages also contribute to sustainable gardening. By promoting vertical growth, they reduce the need for chemical pesticides and encourage natural pest management. Additionally, they allow better air circulation, reducing the risk of fungal diseases common in overcrowded gardens. IStreamCoder coder = converter.getStreamCoder(); In addition to their functional benefits, bulk tomato stakes also promote sustainability. By investing in reusable stakes, you reduce waste and contribute to a more eco-friendly gardening practice. After each season, simply clean and store them properly for reuse the following year. When it comes to aesthetics, wire link fences offer a timeless beauty that complements any environment In addition to enhancing visibility, outdoor sign holder stakes also provide a cost-effective and flexible way to communicate with a target audience. Unlike fixed signage or permanent fixtures, these portable stakes can be easily moved and repositioned as needed. This makes them ideal for temporary promotions, seasonal events, and changing business needs

In addition to enhancing visibility, outdoor sign holder stakes also provide a cost-effective and flexible way to communicate with a target audience. Unlike fixed signage or permanent fixtures, these portable stakes can be easily moved and repositioned as needed. This makes them ideal for temporary promotions, seasonal events, and changing business needs

outdoor sign holder stake. With a wide range of sizes, styles, and materials available, businesses can customize their sign holder stakes to suit their specific requirements and branding. In addition to providing support for plants and creating barriers, 1.2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden

2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden

2mm garden wire can also be used for a variety of other tasks in the garden2mm garden wire can also be used for a variety of other tasks in the garden 1.2 mm garden wire. For example, it can be used to create decorative elements such as plant cages, sculptures, or even woven baskets. The versatility of garden wire makes it a valuable tool for any gardener looking to add a touch of creativity to their outdoor space.

1.2 mm garden wire. For example, it can be used to create decorative elements such as plant cages, sculptures, or even woven baskets. The versatility of garden wire makes it a valuable tool for any gardener looking to add a touch of creativity to their outdoor space. Overall, joint reinforcement plays a critical role in masonry construction by enhancing the strength, stability, and durability of the structure. By incorporating the right type of reinforcement material and following proper installation techniques, builders can create masonry walls that are not only aesthetically pleasing but also structurally sound and resilient to various external forces. Whether it is a residential, commercial, or industrial building, joint reinforcement is an essential component that should not be overlooked in any masonry construction project. In conclusion, field fencing is not just a physical boundary; it's a strategic investment in the safety and productivity of agricultural lands. By understanding the different types and their applications, farmers and landowners can safeguard their assets while fostering a harmonious coexistence with the surrounding environment. The HD Compression Spring is primarily composed of high-strength materials, often heat-treated to enhance durability and performance. Its design, characterized by tightly wound coils, allows it to absorb and discharge pressure effectively, making it ideal for applications where consistent force resistance is crucial. The in the term is a URL encoding for a space, symbolizing the integration of this technology into digital platforms and modern communication. In the world of men's fashion, the stubby tie has carved out a unique niche. This shorter-than-average necktie exudes a charm that transcends the traditional long tie's elegance. It is a testament to individuality and a break from conformity, making it a bold fashion statement for those who dare to wear it. Helical Extension Springs A Comprehensive Guide Installation of brick ties requires precision and adherence to industry standards. Each tie should be placed at regular intervals, typically every 300-600mm, depending on factors like wall height, brick type, and environmental conditions. The correct installation ensures even distribution of load and prevents localized stress points.