Links:

Waterproofing is a crucial step in safeguarding buildings from the damaging effects of water infiltration. Rain, snow, and humidity can lead to severe structural damage, mold growth, and increased energy costs. By incorporating waterproof sheets into your roofing system, you can effectively minimize these risks. These sheets act as a barrier, preventing water from penetrating the roof structure and into the living spaces below.

Conclusion

Türkiye’deki galvanizli demir kapak üreticileri arasından seçerken, ürün kalitesi kadar müşteri hizmetleri ve teslimat süreleri de önemlidir. İyi bir üretici, müşteri ihtiyaçlarını anlamak ve onlara en uygun çözümleri sunmak için çaba sarf etmelidir. Ayrıca, üreticilerin sunduğu garanti ve satış sonrası hizmetler de dikkate alınmalıdır.

5. Pricing While price shouldn’t be the only factor, it’s important to ensure you’re getting a fair deal. Request quotes from multiple suppliers and compare them. Be cautious of prices that seem too low, as they may indicate inferior quality.

To facilitate the use of flax yarn in their designs, Tin Can Knits collaborates with several reputable suppliers who prioritize ethical sourcing and quality production. These suppliers often have a transparent supply chain, ensuring that the flax fibers used in their yarns are grown and processed in a sustainable manner. By partnering with such suppliers, Tin Can Knits can confidently promote patterns that utilize linen and flax yarns, knowing they are supporting responsible practices.

tin can knits flax suppliers

1. Reputation and Experience Choose suppliers with a solid reputation and years of experience in the roofing industry. Reputable suppliers are likely to offer high-quality products and excellent customer service. Look for reviews and testimonials from previous customers to gauge their satisfaction levels.

flashing roof metal sheet suppliers

4. Flux Usage Flux is an important component in soldering, as it helps clean the surface and prevents oxidation during the soldering process. For galvanized iron, a specific type of flux that can handle zinc is recommended. The flux should be applied generously to the joint area to ensure proper solder flow and adhesion.

In summary, 22 gauge corrugated metal roofing is an excellent choice for those seeking a durable, cost-effective, and aesthetically pleasing roofing solution. Its long lifespan, low maintenance requirements, and energy efficiency make it a smart investment for any property. Moreover, its lightweight design facilitates quicker installation, while its variety of styles ensures it can enhance any structure's appearance. As more homeowners and builders recognize these benefits, it’s clear that 22 gauge corrugated metal roofing will continue to be a preferred option in the construction industry. Whether for a new build or an existing structure, investing in quality metal roofing can lead to long-term satisfaction and peace of mind.

The Role of Aluminium Foil Sheets in Roofing A Comprehensive Overview

Market Growth and Consumer Trends

Choosing the Right Supplier

Türkiye’deki galvanizli demir kapak üreticileri, genellikle modern teknoloji ve yüksek kaliteli malzemeler kullanarak üretim yapmaktadır. Bu üreticilerin birçoğu, ISO 9001 gibi kalite sertifikalarına sahiptir. Bu da, ürettikleri ürünlerin uluslararası standartlara uygun olduğunu gösterir. Bununla birlikte, müşteri taleplerine göre özel tasarım kapaklar da üretebilmektedirler.

galvanized iron caps manufacturers

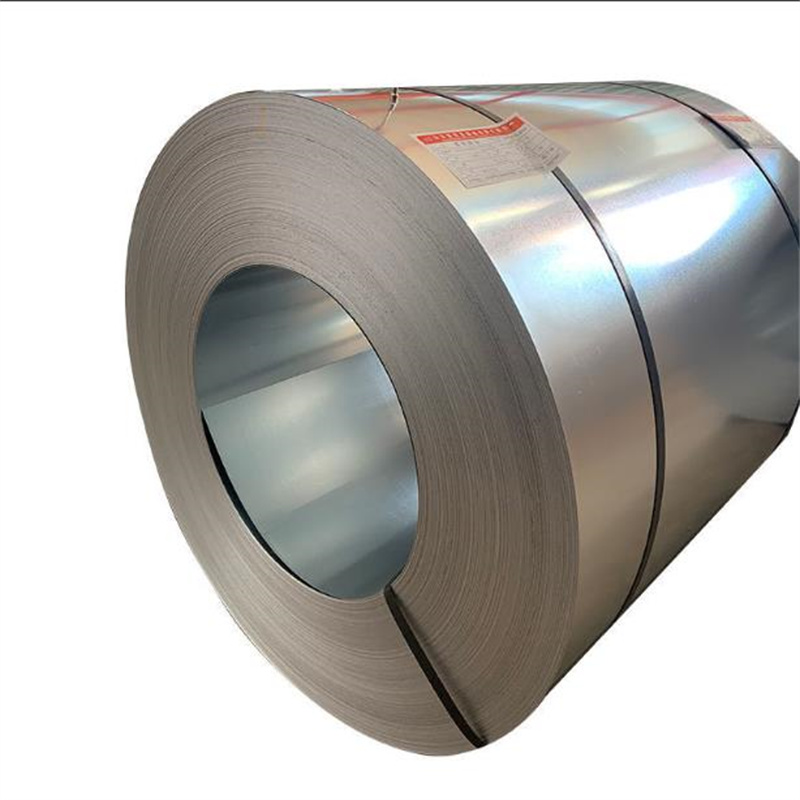

When searching for a coiled galvanized steel supplier, consider factors such as industry reputation, customer service, and product range. Investing time in finding the right supplier will ultimately pay off, ensuring that you receive high-quality materials consistently, which is essential for the success of your projects. In a world where quality and reliability matter more than ever, the decision to buy from a trusted coiled galvanized steel supplier becomes not just advantageous, but essential for your business's growth and sustainability.

2. Thickness and Density Thicker and denser sheets generally provide better soundproofing properties. Manufacturers must consider the intended application and expected noise levels when recommending products to clients.

3. Durability Silicone can withstand extreme temperatures ranging from -40°F to 446°F. As a result, they maintain their integrity over time and can be used repeatedly without wear and tear.

As consumers become more environmentally conscious, the demand for sustainable packaging solutions increases. Tin is a recyclable material, and many wholesale tin box manufacturers emphasize sustainability in their production processes. By choosing tin packaging, businesses can not only enhance their brand image but also appeal to eco-minded consumers.

Suppliers play a vital role in maintaining quality by sourcing products only from trusted manufacturers. They often have established relationships with these manufacturers, allowing them to offer detailed insight into product specifications and certifications. Customers can rely on suppliers to provide information about the origin of the materials, ensuring that they meet local building codes and regulations.

corrugated steel sheet suppliers manufacturers

Market Trends

Selecting the right galvanized iron roof manufacturer is a vital step in ensuring the durability, safety, and aesthetic appeal of your roofing system. By considering factors such as reputation, material quality, product range, technological advancements, compliance with standards, and customer service, you can make an informed decision that meets your needs. Ultimately, investing time in choosing a trustworthy manufacturer will pay off in the form of a resilient and stunning roof that stands the test of time.

With an increasing focus on sustainability, factories producing tin cans with lids are adopting environmentally friendly practices. Tin is a highly recyclable material, and the recycling of tin cans can conserve energy and reduce waste. Many modern factories are implementing closed-loop systems to minimize waste and emissions during production. This not only enhances their sustainability credentials but also positions them favorably in the eyes of environmentally conscious consumers.

tin can with lid factory

When it comes to roofing materials, sheet metal has gained significant popularity for its durability, energy efficiency, and aesthetic appeal. However, the effectiveness and quality of a sheet metal roof largely depend on the supplier you choose. In this article, we will explore the key factors to consider when selecting a reliable sheet metal roof supplier.

Conclusion

The popularity of vintage and retro items, driven by social media and e-commerce platforms where enthusiasts can showcase their collections, has propelled interest in metal lunch boxes. Collectors appreciate the craftsmanship of these lunch boxes, which, unlike plastic alternatives, offer durability and a nostalgic flair. Additionally, limited edition releases from popular franchises further enhance their appeal, making them valuable pieces that can appreciate over time.

Factors Influencing Tin Plate Prices

2. Strength and Stability Galvanized iron boasts impressive strength, making it ideal for applications that require stable, reliable components.

The Importance of Choosing the Right Galvanized Iron Roof Manufacturer

The Vibrant World of Metal Roof Sheet Colors A Guide for Homeowners and Builders

Installation and Maintenance

Soldering galvanized iron poses unique challenges that require careful attention to detail and proper techniques. Manufacturers looking to optimize their soldering processes should focus on thorough surface preparation, the selection of suitable solder, temperature control, and the effective use of flux. By adhering to these practices, manufacturers can achieve strong, durable joints in galvanized iron products, thereby enhancing overall product quality and reliability. As industries continue to evolve, the ability to master soldering techniques for galvanized iron will remain an essential skill for manufacturers striving for excellence.

A Sustainable Choice

In conclusion, the variety of metal roof sheets available on the market today, along with the dedicated efforts of manufacturers, ensures that clients can find the right solution for their roofing needs. With advancements in technology and a commitment to quality, metal roofing remains a top choice for those seeking durability, style, and functionality in their building projects. Whether it’s a residential home or a commercial facility, understanding the types of metal roof sheets and their manufacturers is crucial for making informed decisions.

2. Customization Options Many established suppliers offer customizable solutions for businesses looking to differentiate their products. Whether it's varying sizes, designs, or printed branding, a reliable supplier can accommodate specific needs, helping brands establish a presence in the market.

One of the primary advantages of MGO roof sheets is their eco-friendliness. As the world increasingly focuses on sustainable building practices, materials like MGO that reduce environmental impact are in high demand. The production of MGO sheets involves minimal waste and lower energy consumption, making them a greener alternative compared to traditional roofing materials like asphalt or metal.

These manufacturers invest in advanced technologies and high-grade raw materials to ensure the longevity and reliability of their products. Additionally, many of them engage in sustainable practices, utilizing eco-friendly processes and materials to minimize their environmental impact.

,。,、。,。

cast iron galvanized suppliers

2. Variety of Products A good supplier should offer a range of products in different sizes and specifications. This variety allows clients to find the exact product that meets their project requirements.

The Sustainability Factor

where \( Re \) is the Reynolds number. However, as the flow transitions to a turbulent regime, the calculation becomes more complex. The turbulent flow friction factor is determined using empirical correlations, such as the Colebrook-White equation, which accounts for both the Reynolds number and the relative roughness of the pipe.

friction factor of galvanized iron pipe factory

In conclusion, tin trash can factories represent a convergence of utility, design, sustainability, and economic development. As society continues to evolve in its relationship with waste management, these factories will play an essential role in adapting to changing consumer needs and environmental strategies. The humble tin trash can, often overlooked in the grand scheme of waste disposal, stands as a testament to innovation and the continuous quest for more effective solutions in our daily lives. With ongoing advancements in manufacturing, design, and sustainability, the future of tin trash cans looks promising, aligning with both aesthetic and functional demands of an increasingly eco-aware society.

Looking ahead, the future of steel sheet corrugated factories appears promising. With advancements in technology, there will likely be continued growth in product innovation, improving the performance and capability of corrugated materials. Moreover, as green building practices gain traction worldwide, the demand for sustainable materials, including corrugated steel, is expected to rise.

The history of tin cans dates back to the early 19th century when French inventor Philippe de Girard first patented the tin canning process. Initially developed for the preservation of food, this technology quickly adapted to accommodate various products, including coffee. The first tin coffee cans appeared in the market in the mid-1800s and quickly gained a reputation for keeping coffee fresh longer than other packaging methods.

Another advantage of large metal storage units is the possibility for customization. Manufacturers often offer a range of sizes, colors, and finishes, allowing businesses and individuals to choose options that best fit their specific needs and preferences. Furthermore, businesses can incorporate their branding onto the storage units, turning storage solutions into an extension of their brand identity. This not only enhances the visual appeal of the workspace but also promotes a professional image.

Green metal roofing panels are manufactured using recycled materials, making them a sustainable choice for modern architecture. Typically made from aluminum or steel, these panels boast a lifespan of 40 to 70 years, significantly outpacing traditional roofing materials like asphalt shingles. Beyond durability, metal roofs reflect solar radiant heat, which can help in reducing cooling costs by up to 25%. This reflective property aids in energy conservation, which is crucial in addressing climate change.

In recent years, the automotive industry has witnessed a significant transformation with the advent of electric vehicles (EVs). Among the various categories of EVs, adult electric cars have gained prominence, representing a shift towards more sustainable transportation solutions. This article delves into the factors driving the popularity of adult electric cars, their benefits, and the challenges that lie ahead.

As the global focus shifts toward sustainability, oil tin can manufacturers are adapting to meet consumer demands for environmentally friendly packaging. Tin cans are recyclable, and many manufacturers are now utilizing recycled materials in their production processes. By promoting recycling and reducing waste, these manufacturers contribute to a circular economy that minimizes environmental impact.

oil tin can manufacturer

In Seattle zijn er verschillende lokale bedrijven die gespecialiseerd zijn in de installatie van metalen daken. Deze bedrijven werken vaak samen met Chinese fabrikanten, waardoor ze toegang hebben tot hoogwaardige materialen tegen concurrerende prijzen. Dit creëert een win-win situatie voor zowel de aannemers als de klanten, omdat ze kunnen profiteren van zowel kwaliteit als kostenefficiëntie.

Metal roofing has gained immense popularity in recent years for several reasons. Firstly, its durability is unmatched; metal roofs can last anywhere from 40 to 70 years with proper maintenance, far outlasting traditional roofing materials like asphalt shingles. Additionally, metal roofs are resilient against harsh weather conditions, including high winds, rain, and snow. They are also fire-resistant, making them a safer choice for homeowners. Furthermore, metal roofing is environmentally friendly. Many metal roofs are made from recycled materials and can be recycled at the end of their life cycle, promoting sustainability.

Quality control in tin can manufacturing is paramount. The cookies must maintain strict adherence to size and thickness specifications to ensure proper stacking and sealing. A deviation from these standards can result in production delays, increased costs, or compromised product safety. Manufacturers use advanced technologies such as laser measurement systems and automated inspection processes to monitor every stage of production. Regular audits and adherence to industry standards help manufacturers maintain the quality and safety of their tin can products.

Compared to traditional roofing materials like asphalt shingles or tiles, metal roofing is significantly lighter. This lightweight characteristic allows for easier handling and transportation, especially for longer panels such as the 14-foot option. A lightweight roof can also lighten the load on building structures, which is particularly advantageous for older buildings or those built with lighter materials. The ease of installation associated with metal roofing can reduce labor costs and time, making it a practical choice for both DIY enthusiasts and professional contractors.

Additionally, the potential for collaboration with artists and spiritual leaders can lead to unique offerings that deepen the box's significance beyond a mere container. Workshops that promote the art of writing prayers and customizing boxes could serve as a community-building tool, bridging the gap between spirituality and creativity.