Links:

Hazard Identification

Types of Redispersible Polymer Powders

What are Redispersible Polymer Powders?

In conclusion, HPMC suppliers are integral to several industries, providing essential materials that contribute to product efficacy and quality. Understanding their role and the characteristics that define reputable suppliers is crucial for businesses seeking to incorporate HPMC into their products. As the market continues to expand, the importance of establishing strong relationships with reliable suppliers will only grow, ensuring that industries can successfully meet evolving consumer demands.

HPMC is renowned for its water solubility, thickening, film-forming, and stabilizing properties. These characteristics make it suitable for a vast range of applications.

HPMC serves several roles in the food industry, such as a thickening agent, emulsifier, and stabilizer in sauces, dressings, and desserts. It improves texture and mouthfeel, enhancing the consumer experience. As it is plant-derived and has low-caloric content, it is often preferred in food formulations targeting health-conscious consumers.

In the construction sector, redispersible powders play a crucial role in the manufacture of cement-based materials. They are commonly used in tile adhesives, self-leveling compounds, and repair mortars. When added to these products, redispersible powders improve adhesion, flexibility, and durability. For instance, in tile adhesives, they allow for better wetting properties, ensuring that the adhesive bonds effectively to tiles, even in challenging conditions such as high humidity or varied temperatures.

Quality control is paramount for HPMC, particularly when it comes to food and pharmaceutical applications. Chinese manufacturers are increasingly adopting stringent quality assurance processes to assure their clients of compliance with international safety and quality standards. Many manufacturers also invest in research and development to enhance product formulations, focusing on the development of specialized HPMC grades that cater to specific industry requirements.

Hydroxypropyl Methylcellulose plays a significant role in the dietary supplement industry, acting as a binding agent, stabilizer, and a vegetarian-friendly alternative to gelatin. Its functional properties allow for innovative formulations that enhance the consumer experience, making it a vital ingredient in many products on the market today. As always, consumers should approach supplementation with knowledge and care, ensuring that they select high-quality products that meet their health needs.

One of the most significant characteristics of vinyl acetate ethylene redispersible powder is its excellent adhesion properties. It bonds well to a variety of substrates, including concrete, wood, and metal, ensuring strong and durable end products. Additionally, VAE RP offers flexibility and elasticity, allowing materials to withstand deformation without cracking or losing adhesion. This capability is especially beneficial in construction, where shifting structures can put stress on building materials.

2. Food Industry

Understanding HPMC Density Properties and Applications

Redispersible emulsion powder is a significant innovation in the realm of building materials and formulations. Its unique properties, combined with its versatility, make it an essential component in various applications, particularly in the construction sector. As industries move towards more sustainable practices, the role of REP is likely to expand, fostering innovations that enhance performance while minimizing environmental impact.

5. Consider Regulatory Compliance Depending on your industry, ensure that the HPMC meets specific regulatory standards. For food and pharmaceutical applications, it is imperative to purchase HPMC that complies with FDA requirements or any other relevant health and safety regulations.

HPMC in Food Processing

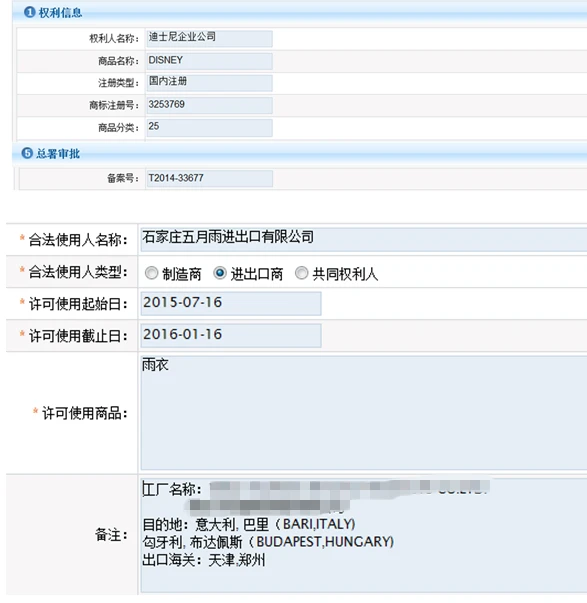

china hpmc

The Basics of Cell Size

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose, which has become increasingly popular across various industries due to its multifunctional properties. This versatile compound acts as a thickening agent, emulsifier, and stabilizer, making it essential in formulations for products like paints, coatings, pharmaceuticals, personal care items, and construction materials.

The Importance of HPMC in Construction

Conclusion

What is Redispersible Powder Polymer?

HPMC safety refers to the comprehensive approach adopted to safeguard high-performance computing systems and their users against various risks. This includes ensuring that hardware, software, data integrity, and user safety are maintained to prevent accidents and data breaches. Due to the complex nature of HPC environments, particularly those that involve multiple users and high-value data, a focused approach toward safety is essential.

Properties of HPMC

In the cosmetics sector, HEC is commonly found in lotions, creams, shampoos, and various personal care products. It acts as a thickener and stabilizer, improving the texture and consistency of these formulations. Moreover, HEC contributes to the moisturizing properties of cosmetic products by forming a protective film on the skin, which helps retain hydration and improve overall skin health. Its gentle nature makes it suitable for sensitive skin formulations, further expanding its usability in the cosmetic market.

hydroxyethyl cellulose hec

Redispersible powders have become an integral component in the construction industry, especially when it comes to enhancing the properties of materials like tile adhesives, mortars, and other cementitious systems. These powders, when mixed with water, redisperse into their original polymer emulsion form, offering a myriad of benefits to the final product. Let’s delve into the different types of redispersible powders and their unique characteristics.

Self-leveling flooring compounds are another area where redispersible powder is invaluable. These compounds are designed to create a flat, level surface without the need for extensive labor. The use of redispersible powder in these formulations provides excellent flow characteristics and reduces the risk of shrinkage cracks, resulting in a durable and long-lasting floor finish.