Links:

-

In addition to their functional benefits, fiberglass tanks are environmentally friendly. Their non-toxic composition ensures that they do not leach harmful substances into the stored liquid or the surrounding environment. At the end of their service life, these tanks can be recycled, further contributing to sustainability efforts. Fiber Reinforced Polymer (FRP) dual laminate products have emerged as a revolutionary material in the world of composite engineering due to their exceptional performance characteristics and versatility. This innovative technology combines two distinct layers, each with its own unique properties, to create a composite material that surpasses many traditional construction materials. One of the key advantages of using frp weirs is their high strength-to-weight ratio. Frp materials are lightweight yet incredibly strong, making them ideal for use in water control structures where weight is a concern. Unlike traditional materials like concrete or steel, frp weirs are easy to transport, install, and maintain, saving time and resources for industries. One of the key advantages of FRP mining equipment is its lightweight nature. Due to the lightweight properties of fiberglass materials, FRP equipment is much easier to transport and handle compared to metal equipment. This not only increases portability but also reduces the risk of workplace injuries that can occur when handling heavy machinery. Additionally, the lightweight nature of FRP equipment allows for easier maneuverability in tight spaces, making it an ideal choice for mining operations in confined areas. The strength-to-weight ratio of FRP pipes is unparalleled. Despite their lightweight, they can withstand high pressure and loads, making them suitable for various industrial applications such as oil and gas, water supply, waste management, and chemical processing. They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries

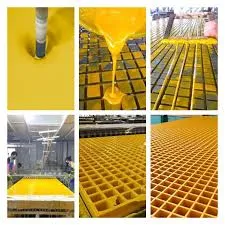

- Safety surface: Molded Grating offers an outstanding skid-resistant concave surface as an option. A molded-in grit surface is also available to provide sure footing for worker safety, yet its non-porous qualities help eliminate bacterial breeding areas in food applications.

- shipping centers The material selection for these rods is also of paramount importance. Typically constructed from high-grade steel alloys, they are designed to endure the rigorous demands of rock drilling. The composition of these alloys provides a balance between strength and flexibility, ensuring that the rods can bend without breaking under the weight of the rock and the force of the drill. In the vast toolbox of craftsmanship and engineering, hole cutter drill bits stand as silent yet essential artists in the symphony of creation. These specialized tools, also known as hole saws or hole cutters, are engineered marvels designed to carve perfect circular holes in a variety of materials, from wood and plastic to metal and concrete. Their significance transcends mere functionality; they embody precision, efficiency, and innovation. A lightweight jack hammer is an essential tool for any construction or demolition project. Its portable design and powerful performance make it ideal for breaking up concrete, asphalt, and other hard materials with ease. In this article, we will explore the benefits of using a lightweight jack hammer and its versatility in various applications. Conclusion The 90% Pneumatic Jackhammer A Revolution in Construction Efficiency

They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries

They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries They also exhibit excellent thermal and electrical insulation properties, adding to their utility in specific industries frp pipe.

frp pipe. This also adds to how flexible FRP grating is, as its lightweight nature makes it flexible and easy to cut. Because of this, it is simple to customize this grating to fit the project.

In conclusion, the core drill bit extension rod is an essential component for any drilling operation seeking to optimize its performance. It not only allows for deeper penetration but also ensures that the process remains accurate and stable. By improving operational efficiency and safety, these extension rods are indispensable tools for professionals navigating the complexities of modern drilling demands. In addition to industrial applications, fiberglass floor grating is also used in commercial and residential settings, such as parking garages, swimming pool decks, and mezzanine floors. Its aesthetic appeal, combined with its functional benefits, makes it a popular choice for architects and designers. The primary advantage of hardened drill bits lies in their ability to maintain their sharpness and cutting edge under heavy loads and repetitive use. Unlike standard drill bits, which can quickly become dull and ineffective, hardened drill bits are made from materials that are specifically formulated to resist wear and tear. This means that they can maintain their cutting efficiency over longer periods of time, resulting in faster drilling times and reduced downtime. One of the standout features of the 90% Pneumatic Jackhammer is its versatility Additionally, fiberglass stair treads are easy to clean and maintain fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.

fiberglass stair tread. Unlike wood stair treads, which may require sanding, staining, or refinishing over time, fiberglass stair treads can be simply wiped clean with a damp cloth or mild detergent. This makes them a cost-effective choice for busy households or commercial buildings where maintenance time and costs are a concern.  long flexible drill bit extension. It efficiently transfers the rotational force from the drill to the bit, ensuring that the user can apply adequate torque to complete their task effectively. Additionally, some models come equipped with a magnetic tip holder, adding convenience by keeping spare bits within easy reach during operation. Corrosion-Resistant FRP Revolutionizing Infrastructure Protection Another advantage of tungsten carbide button bits is their versatility. They can be used in a variety of drilling applications, including core drilling, percussion drilling, and rotary drilling. Whether you're working in quarrying, mining, or construction, these bits have the power to get the job done.

long flexible drill bit extension. It efficiently transfers the rotational force from the drill to the bit, ensuring that the user can apply adequate torque to complete their task effectively. Additionally, some models come equipped with a magnetic tip holder, adding convenience by keeping spare bits within easy reach during operation. Corrosion-Resistant FRP Revolutionizing Infrastructure Protection Another advantage of tungsten carbide button bits is their versatility. They can be used in a variety of drilling applications, including core drilling, percussion drilling, and rotary drilling. Whether you're working in quarrying, mining, or construction, these bits have the power to get the job done. Moreover, the non-combustible nature of fiberglass makes it a preferred choice in fire-sensitive environments. It has a high-temperature tolerance, contributing to overall safety in industrial settings. Its non-corrosive property further ensures that it doesn't react with acidic or alkaline fluids, preserving the integrity of the pipe material. In the realm of metalworking and manufacturing, precision is paramount. This is especially true when it comes to drilling operations, where accuracy and efficiency are critical to achieving desired results. One innovative solution that has emerged to address these challenges is the tapered drill bit. Another important consideration when selecting a rock drill shank adapter is its durability Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency.

Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency.

Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency.

Despite their robustness, fiberglass tanks require regular maintenance to ensure their longevity. This includes periodic inspections for cracks or signs of wear, especially around seals and joints. Prompt repairs and proper cleaning help to extend the tank's lifespan and maintain its efficiency. In the world of drilling and construction, the hexagonal drill rod stands as a testament to the fusion of engineering prowess and practical innovation. This specialized tool, with its unique hexagonal shape, has revolutionized drilling operations, offering improved efficiency and precision in various applications. One of the key advantages of fiberglass vessels is their lightweight nature. Due to the low density of the material, these boats can achieve higher speed with less power, translating into fuel efficiency and cost savings. Moreover, the reduced weight also makes them easier to maneuver and maintain, enhancing the overall user experience. The primary function of a truck extension rod lies in its ability to extend the truck's bed, thereby increasing its payload capacity. This feature is particularly beneficial for transporting large or bulky items that may exceed the standard dimensions of a truck bed. By extending the reach, it enables the driver to load and unload items more efficiently, reducing the need for additional vehicles or complex loading mechanisms. Blasting and drilling contractor, BHP Billiton, is another major force in the sector rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry. However, the importance of the button bit extends beyond its functional aspects. It embodies the human desire for control and connection in an increasingly digital world. Each press, tap, or swipe is a form of expression, a way to engage with technology on our terms.

rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry. However, the importance of the button bit extends beyond its functional aspects. It embodies the human desire for control and connection in an increasingly digital world. Each press, tap, or swipe is a form of expression, a way to engage with technology on our terms.  One of the key benefits of using a rod drilling machine is its efficiency. The machine is designed to drill holes quickly and accurately, allowing for faster production and improved overall productivity. This can help businesses save time and money by reducing the need for manual labor and increasing output. The 75mm drill bit is a staple in many workshops and construction sites due to its sizeable diameter, which allows for rapid drilling of large holes. Its scale lends it to a variety of tasks, from creating anchor points in walls for heavy fixtures to preparing sites for piping and ductwork. The bit's wide span also makes it a favorite for projects that demand ample clearance, such as electrical installations or when working with large timber. One of the key advantages of bit drilling is its versatility. Different types of drill bits can be used to meet specific drilling requirements, such as the hardness of the material being drilled, the desired hole size, and the depth of the hole. For example, tricone drill bits are commonly used in the oil and gas industry for drilling through hard rock formations, while diamond core drill bits are used in mining and construction for cutting through concrete and other tough materials. The history of colonialism is marked by the displacement and oppression of indigenous peoples. One aspect of this is the impact on settler groups who were brought to colonize these lands. This article explores the effects of colonialism on settler groups, including their cultural identity, social structure, and relationship with the indigenous population.

One of the key benefits of using a rod drilling machine is its efficiency. The machine is designed to drill holes quickly and accurately, allowing for faster production and improved overall productivity. This can help businesses save time and money by reducing the need for manual labor and increasing output. The 75mm drill bit is a staple in many workshops and construction sites due to its sizeable diameter, which allows for rapid drilling of large holes. Its scale lends it to a variety of tasks, from creating anchor points in walls for heavy fixtures to preparing sites for piping and ductwork. The bit's wide span also makes it a favorite for projects that demand ample clearance, such as electrical installations or when working with large timber. One of the key advantages of bit drilling is its versatility. Different types of drill bits can be used to meet specific drilling requirements, such as the hardness of the material being drilled, the desired hole size, and the depth of the hole. For example, tricone drill bits are commonly used in the oil and gas industry for drilling through hard rock formations, while diamond core drill bits are used in mining and construction for cutting through concrete and other tough materials. The history of colonialism is marked by the displacement and oppression of indigenous peoples. One aspect of this is the impact on settler groups who were brought to colonize these lands. This article explores the effects of colonialism on settler groups, including their cultural identity, social structure, and relationship with the indigenous population.

rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry. However, the importance of the button bit extends beyond its functional aspects. It embodies the human desire for control and connection in an increasingly digital world. Each press, tap, or swipe is a form of expression, a way to engage with technology on our terms.

rock drilling companies. Their expertise spans across exploration, development, and operation of mines, making them a comprehensive service provider. BHP's focus on safety and responsible mining practices sets a benchmark for the industry. However, the importance of the button bit extends beyond its functional aspects. It embodies the human desire for control and connection in an increasingly digital world. Each press, tap, or swipe is a form of expression, a way to engage with technology on our terms. 4. Percussion Drills Percussion drills use a pneumatic hammer to drive a cutting tool into the ground. They are ideal for drilling deep holes and are often used in mining and geological exploration.

See our Chemical Resistance Guide and Resin Selection Guide for more information and to determine which resin system is right for your application.

Coupling sleeves come in various types, including straight, 90-degree elbow, and tee configurations, catering to the diverse needs of hydraulic systems. Their use can significantly reduce downtime during maintenance or repair, as they allow quick and easy disconnection without the need for welding or pipe cutting. The 20th century witnessed the advent of electric and hydraulic coal-cutting machines. These powerful tools could cut through coal seams with precision and speed, further minimizing manual labor and boosting productivity. Electric drills and saws also became essential for creating openings and driving tunnels deep into coal measures, making mining operations more extensive and efficient than ever before. Despite their numerous advantages, FRP ducts do have some limitations that are worth considering One of the key benefits of using a rod drilling machine is its efficiency. The machine is designed to drill holes quickly and accurately, allowing for faster production and improved overall productivity. This can help businesses save time and money by reducing the need for manual labor and increasing output. The 75mm drill bit is a staple in many workshops and construction sites due to its sizeable diameter, which allows for rapid drilling of large holes. Its scale lends it to a variety of tasks, from creating anchor points in walls for heavy fixtures to preparing sites for piping and ductwork. The bit's wide span also makes it a favorite for projects that demand ample clearance, such as electrical installations or when working with large timber. One of the key advantages of bit drilling is its versatility. Different types of drill bits can be used to meet specific drilling requirements, such as the hardness of the material being drilled, the desired hole size, and the depth of the hole. For example, tricone drill bits are commonly used in the oil and gas industry for drilling through hard rock formations, while diamond core drill bits are used in mining and construction for cutting through concrete and other tough materials. The history of colonialism is marked by the displacement and oppression of indigenous peoples. One aspect of this is the impact on settler groups who were brought to colonize these lands. This article explores the effects of colonialism on settler groups, including their cultural identity, social structure, and relationship with the indigenous population.

One of the key benefits of using a rod drilling machine is its efficiency. The machine is designed to drill holes quickly and accurately, allowing for faster production and improved overall productivity. This can help businesses save time and money by reducing the need for manual labor and increasing output. The 75mm drill bit is a staple in many workshops and construction sites due to its sizeable diameter, which allows for rapid drilling of large holes. Its scale lends it to a variety of tasks, from creating anchor points in walls for heavy fixtures to preparing sites for piping and ductwork. The bit's wide span also makes it a favorite for projects that demand ample clearance, such as electrical installations or when working with large timber. One of the key advantages of bit drilling is its versatility. Different types of drill bits can be used to meet specific drilling requirements, such as the hardness of the material being drilled, the desired hole size, and the depth of the hole. For example, tricone drill bits are commonly used in the oil and gas industry for drilling through hard rock formations, while diamond core drill bits are used in mining and construction for cutting through concrete and other tough materials. The history of colonialism is marked by the displacement and oppression of indigenous peoples. One aspect of this is the impact on settler groups who were brought to colonize these lands. This article explores the effects of colonialism on settler groups, including their cultural identity, social structure, and relationship with the indigenous population.