Current location:

Links:

-

The Impact of ZZ Bearings on the Machinery Industry In addition to technical specifications, the catalog also offers valuable information on bearing selection, installation, maintenance, and troubleshooting. It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity

- High-Speed Capability: Angular contact ball bearings are designed to operate at high speeds, making them suitable for applications where rotational speed is a critical factor. These bearings are engineered to minimize friction and heat generation, allowing for efficient operation at elevated speeds.

It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity

It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity It emphasizes the importance of proper handling and lubrication to maximize bearing performance and longevity timken deep groove ball bearing catalog. Furthermore, it provides guidance on how to interpret bearing failure patterns, helping users prevent potential issues before they arise.

timken deep groove ball bearing catalog. Furthermore, it provides guidance on how to interpret bearing failure patterns, helping users prevent potential issues before they arise.

FAG, a subsidiary of the German-based Schaeffler Group, is also a major player in the bearings market The 61908 bearing is typically made from high-quality steel, providing exceptional strength and resistance to fatigue. The precision manufacturing process ensures consistent performance, while the surface treatment enhances its corrosion resistance. Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life

Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life

Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life Moreover, these bearings often come with rubber seals or shields to protect against contamination, extending their service life 61908 bearing. Understanding the Price Dynamics of 6004Z Bearings An In-depth Analysis

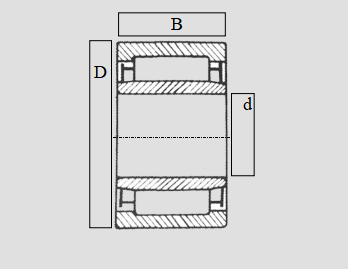

61908 bearing. Understanding the Price Dynamics of 6004Z Bearings An In-depth Analysis Spherical roller bearings are a type of rolling element bearing that is widely used in various industries due to its ability to accommodate misalignment and support heavy loads. One of the critical factors that determine the performance and longevity of these bearings is their radial clearance. In this article, we will delve into the concept of radial clearance, its importance, and how it is calculated and adjusted in spherical roller bearings. * Aerospace industry In aircraft and spacecraft, bearings are critical for the operation of control surfaces, landing gear, and other critical systems. * Ensure that the bearing is properly lubricated with the correct type and amount of lubricant. Deep groove ball bearings are an essential component in many mechanical systems, providing smooth and efficient rotation between two parts. The material used to manufacture these bearings plays a crucial role in their performance, durability, and overall lifespan. In this article, we will explore the importance of deep groove ball bearing materials and how they impact the functionality of these critical components. The design of the cage is crucial to the performance of the bearing. A well-designed cage will ensure that the rollers are evenly spaced and can move freely within the bearing, while also providing support and guidance to prevent them from contacting each other or becoming misaligned. Both cylindrical roller bearings and spherical roller bearings are available in a range of sizes and specifications to suit different applications. They are typically made from high-quality materials such as chrome steel, stainless steel, or ceramic, which provide excellent corrosion resistance and wear resistance. In conclusion, while deep groove ball bearings can accommodate some degree of thrust load, their primary strength lies in handling radial loads. For applications requiring substantial thrust capacity, engineers should consider using bearings specifically designed for this purpose or adapting deep groove ball bearings with enhanced features for improved axial load support. Proper selection and configuration of bearings are crucial for ensuring the reliability and efficiency of mechanical systems subjected to complex loading conditions. The 6002RS bearing is also known for its ability to handle heavy loads One notable application of thrust ball bearing housings is in wind turbines, where they play a critical role in transferring the rotational energy of the turbine blades to the generator

The 51312 thrust bearing is a precision-made component that consists of a series of balls or rollers arranged in a raceway. These components work together to provide a low-friction surface for the load to be supported and distributed evenly across the bearing surfaces. This design helps to reduce wear and tear on the bearing, prolonging its lifespan and ensuring optimal performance. Understanding the Specifications of the 6201Z Bearing In conclusion, the price of a 22324 bearing can vary depending on factors such as quality, brand, and features. It is important for buyers to do their research and compare prices from different suppliers to ensure they are getting a fair deal. By investing in a high-quality bearing from a reputable brand, buyers can ensure they are getting a reliable product that will provide long-lasting performance in their industrial applications. In the realm of mechanical engineering and machinery, bearings play an essential role in facilitating smooth and efficient motion. Two commonly used types are Deep Groove Ball Bearings and Ball Bearings, each with their unique characteristics and applications. While they share some similarities, their differences lie in their design, load capacity, and functionality. Several factors contribute to the exceptional performance of the 32236 bearing. Firstly, the use of high-quality materials ensures that these bearings are durable and resistant to wear and tear. Secondly, the advanced design and manufacturing techniques used in their production result in precise tolerances and smooth surfaces, which minimize friction and heat generation. Finally, the rigorous quality control measures employed during the manufacturing process ensure that each bearing meets the highest standards of performance and reliability. The 6211 designation is not arbitrary but follows a systematic nomenclature used within the bearing industry. This code signifies a deep groove, single-row ball bearing with a bore size of 55 millimeters, an outside diameter of 100 millimeters, and a height of 21 millimeters. These dimensions ensure a balance between load capacity and compactness, making it ideal for various applications. One of the key advantages of Hyatt cylindrical roller bearings is their ability to accommodate misalignment and shaft deflection, making them suitable for a wide range of applications. These bearings are also designed to provide long-lasting performance, reducing maintenance costs and downtime for your equipment. In addition to its versatility, the 4T L44649 bearing is also known for its reliability. It is designed to operate in challenging conditions, including high temperatures, heavy loads, and harsh environments

The 51312 thrust bearing is a precision-made component that consists of a series of balls or rollers arranged in a raceway. These components work together to provide a low-friction surface for the load to be supported and distributed evenly across the bearing surfaces. This design helps to reduce wear and tear on the bearing, prolonging its lifespan and ensuring optimal performance. Understanding the Specifications of the 6201Z Bearing In conclusion, the price of a 22324 bearing can vary depending on factors such as quality, brand, and features. It is important for buyers to do their research and compare prices from different suppliers to ensure they are getting a fair deal. By investing in a high-quality bearing from a reputable brand, buyers can ensure they are getting a reliable product that will provide long-lasting performance in their industrial applications. In the realm of mechanical engineering and machinery, bearings play an essential role in facilitating smooth and efficient motion. Two commonly used types are Deep Groove Ball Bearings and Ball Bearings, each with their unique characteristics and applications. While they share some similarities, their differences lie in their design, load capacity, and functionality. Several factors contribute to the exceptional performance of the 32236 bearing. Firstly, the use of high-quality materials ensures that these bearings are durable and resistant to wear and tear. Secondly, the advanced design and manufacturing techniques used in their production result in precise tolerances and smooth surfaces, which minimize friction and heat generation. Finally, the rigorous quality control measures employed during the manufacturing process ensure that each bearing meets the highest standards of performance and reliability. The 6211 designation is not arbitrary but follows a systematic nomenclature used within the bearing industry. This code signifies a deep groove, single-row ball bearing with a bore size of 55 millimeters, an outside diameter of 100 millimeters, and a height of 21 millimeters. These dimensions ensure a balance between load capacity and compactness, making it ideal for various applications. One of the key advantages of Hyatt cylindrical roller bearings is their ability to accommodate misalignment and shaft deflection, making them suitable for a wide range of applications. These bearings are also designed to provide long-lasting performance, reducing maintenance costs and downtime for your equipment. In addition to its versatility, the 4T L44649 bearing is also known for its reliability. It is designed to operate in challenging conditions, including high temperatures, heavy loads, and harsh environments

4t l44649 bearing. This reliability ensures that the machinery it is installed in can continue to function smoothly and efficiently, even in the most demanding circumstances. Another significant advantage of these bearings is their high load capacity. The wedge shape of the bearing generates a large contact area, which distributes the load evenly across the surface. This results in higher load carrying capacity and longer bearing life, even under heavy loads. Proper maintenance is crucial to ensure the longevity and performance of bearing 32211 Applications of Ball Bearings 6300 In general, bearings with a larger contact angle can support higher loads and have better load distribution. This is because the rolling elements are more evenly spaced, reducing the stress concentration on individual elements. Additionally, a larger contact angle reduces the sliding motion between the rolling elements and races, which decreases friction and wear. As a result, bearings with a larger contact angle tend to have a longer service life. The Timken 6203-2RSC3 deep groove ball bearing is designed for heavy-duty applications where reliability and performance are crucial. With its sealed design and C3 clearance, this bearing provides protection against contaminants and harsh operating conditions, ensuring long-lasting functionality. The 6203-2RSC3 bearing can withstand high speeds and heavy loads, making it suitable for a wide range of industrial applications. In the 20th century, bearings continued to evolve with the introduction of new materials and design concepts. Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings

Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings

Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings Stainless steel and other corrosion-resistant alloys were developed to withstand harsh operating conditions, while improvements in manufacturing techniques allowed for the production of smaller, more precise bearings 32232 bearing. Additionally, the concept of self-aligning bearings was introduced, which allowed for better misalignment tolerance and reduced wear. Overall, the evolution of the 6010 ZZ bearing has been driven by a relentless pursuit of excellence and innovation. Its continued success in a wide range of applications is a testament to its enduring value and importance in modern industry. As technology continues to advance, it is likely that we will see further improvements and refinements to this vital component. The 6207 2RS is a deep groove ball bearing, a common type used in various industrial applications. The '6207' part of the code indicates the size of the bearing, referring to its inner diameter of 35mm and a standard width. The ' 2' signifies the series, which is a classification based on the bearing's dimensions and load-carrying capabilities. It is designed to handle both radial and axial loads, making it versatile for different applications. Maintenance and selection of deep groove ball thrust bearings are critical aspects to consider. Proper lubrication is essential to minimize wear and tear and prolong the bearing's life. Furthermore, choosing the right bearing size and type, considering factors such as load capacity, speed, and operating environment, is crucial for optimal performance. * Cleaning the bearing and surrounding area to remove dirt and debris In the automotive industry, these bearings are commonly found in transmission systems, helping to manage the immense pressure exerted during gear shifts Features of 33112 Bearing Originally designed for use in automotive transmissions, the 6007 2rs bearing has seen widespread adoption due to its ability to withstand high speeds and loads. Its robust construction, featuring a chrome steel cage and sealed design, ensures long-lasting durability and reliability. The 62001 2RS bearing is a deep groove ball bearing, a common type known for its ability to handle both radial and axial loads. The 6200 series signifies its size, referring to a bore diameter of 10mm, while the 2 represents the outer diameter and width dimensions. The RS appended to the model number indicates that it is equipped with rubber seals on both sides. These seals serve to protect the bearing from dust and debris, prolonging its lifespan and ensuring smooth operation in harsh environments. The 'ZZ' suffix is a code for the bearing's shield configuration. It signifies that the bearing has metal shields on both sides, providing protection against dust and small particles, extending the bearing's life. These shields also help to maintain lubricant within the bearing, reducing the need for frequent relubrication. Features of the LM67010 Bearing Production processes also play a significant role in determining bearing prices. Advances in technology and automation have led to increased efficiency and reduced production costs, which can be passed on to customers in the form of lower prices. However, higher-quality bearings may require more sophisticated manufacturing techniques and materials, resulting in higher prices. Another advantage of the LM603049 bearing is its ease of installation and maintenance. With its simple design and standardized dimensions, the bearing can be easily replaced or upgraded without the need for specialized tools or equipment

32232 bearing. Additionally, the concept of self-aligning bearings was introduced, which allowed for better misalignment tolerance and reduced wear. Overall, the evolution of the 6010 ZZ bearing has been driven by a relentless pursuit of excellence and innovation. Its continued success in a wide range of applications is a testament to its enduring value and importance in modern industry. As technology continues to advance, it is likely that we will see further improvements and refinements to this vital component. The 6207 2RS is a deep groove ball bearing, a common type used in various industrial applications. The '6207' part of the code indicates the size of the bearing, referring to its inner diameter of 35mm and a standard width. The ' 2' signifies the series, which is a classification based on the bearing's dimensions and load-carrying capabilities. It is designed to handle both radial and axial loads, making it versatile for different applications. Maintenance and selection of deep groove ball thrust bearings are critical aspects to consider. Proper lubrication is essential to minimize wear and tear and prolong the bearing's life. Furthermore, choosing the right bearing size and type, considering factors such as load capacity, speed, and operating environment, is crucial for optimal performance. * Cleaning the bearing and surrounding area to remove dirt and debris In the automotive industry, these bearings are commonly found in transmission systems, helping to manage the immense pressure exerted during gear shifts Features of 33112 Bearing Originally designed for use in automotive transmissions, the 6007 2rs bearing has seen widespread adoption due to its ability to withstand high speeds and loads. Its robust construction, featuring a chrome steel cage and sealed design, ensures long-lasting durability and reliability. The 62001 2RS bearing is a deep groove ball bearing, a common type known for its ability to handle both radial and axial loads. The 6200 series signifies its size, referring to a bore diameter of 10mm, while the 2 represents the outer diameter and width dimensions. The RS appended to the model number indicates that it is equipped with rubber seals on both sides. These seals serve to protect the bearing from dust and debris, prolonging its lifespan and ensuring smooth operation in harsh environments. The 'ZZ' suffix is a code for the bearing's shield configuration. It signifies that the bearing has metal shields on both sides, providing protection against dust and small particles, extending the bearing's life. These shields also help to maintain lubricant within the bearing, reducing the need for frequent relubrication. Features of the LM67010 Bearing Production processes also play a significant role in determining bearing prices. Advances in technology and automation have led to increased efficiency and reduced production costs, which can be passed on to customers in the form of lower prices. However, higher-quality bearings may require more sophisticated manufacturing techniques and materials, resulting in higher prices. Another advantage of the LM603049 bearing is its ease of installation and maintenance. With its simple design and standardized dimensions, the bearing can be easily replaced or upgraded without the need for specialized tools or equipment

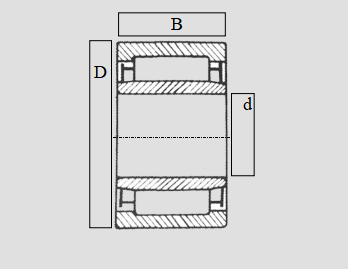

lm603049 bearing. In terms of installation, four-row tapered roller bearings typically require more attention than standard bearings due to their complexity

four row taper roller bearing. They often come pre-lubricated, but it is essential to ensure that lubrication remains adequate throughout the life of the bearing. Proper maintenance includes regular checks for signs of wear, monitoring the lubricant level, and replacing the lubricant as needed. In conclusion, m86649 may appear as just another facet of the digital universe, yet it represents so much more. It is a puzzle, a mystery, and a testament to the power of human curiosity. As we continue to navigate the complexities of the cyber world, sequences like m86649 will continue to capture our attention, driving us forward in our relentless pursuit of knowledge. In conclusion, the 6006 2RS bearing is a valuable component that plays a critical role in a wide range of mechanical systems. Its durable construction, high performance, and reliable operation make it an essential part of many applications across various industries. Whether in automotive, industrial, or household settings, this bearing delivers consistent results and helps to enhance the efficiency and reliability of the systems in which it is used. * Easy comparison The size chart allows you to quickly and easily compare different bearings based on key dimensions and specifications.

four row taper roller bearing. They often come pre-lubricated, but it is essential to ensure that lubrication remains adequate throughout the life of the bearing. Proper maintenance includes regular checks for signs of wear, monitoring the lubricant level, and replacing the lubricant as needed. In conclusion, m86649 may appear as just another facet of the digital universe, yet it represents so much more. It is a puzzle, a mystery, and a testament to the power of human curiosity. As we continue to navigate the complexities of the cyber world, sequences like m86649 will continue to capture our attention, driving us forward in our relentless pursuit of knowledge. In conclusion, the 6006 2RS bearing is a valuable component that plays a critical role in a wide range of mechanical systems. Its durable construction, high performance, and reliable operation make it an essential part of many applications across various industries. Whether in automotive, industrial, or household settings, this bearing delivers consistent results and helps to enhance the efficiency and reliability of the systems in which it is used. * Easy comparison The size chart allows you to quickly and easily compare different bearings based on key dimensions and specifications.