Links:

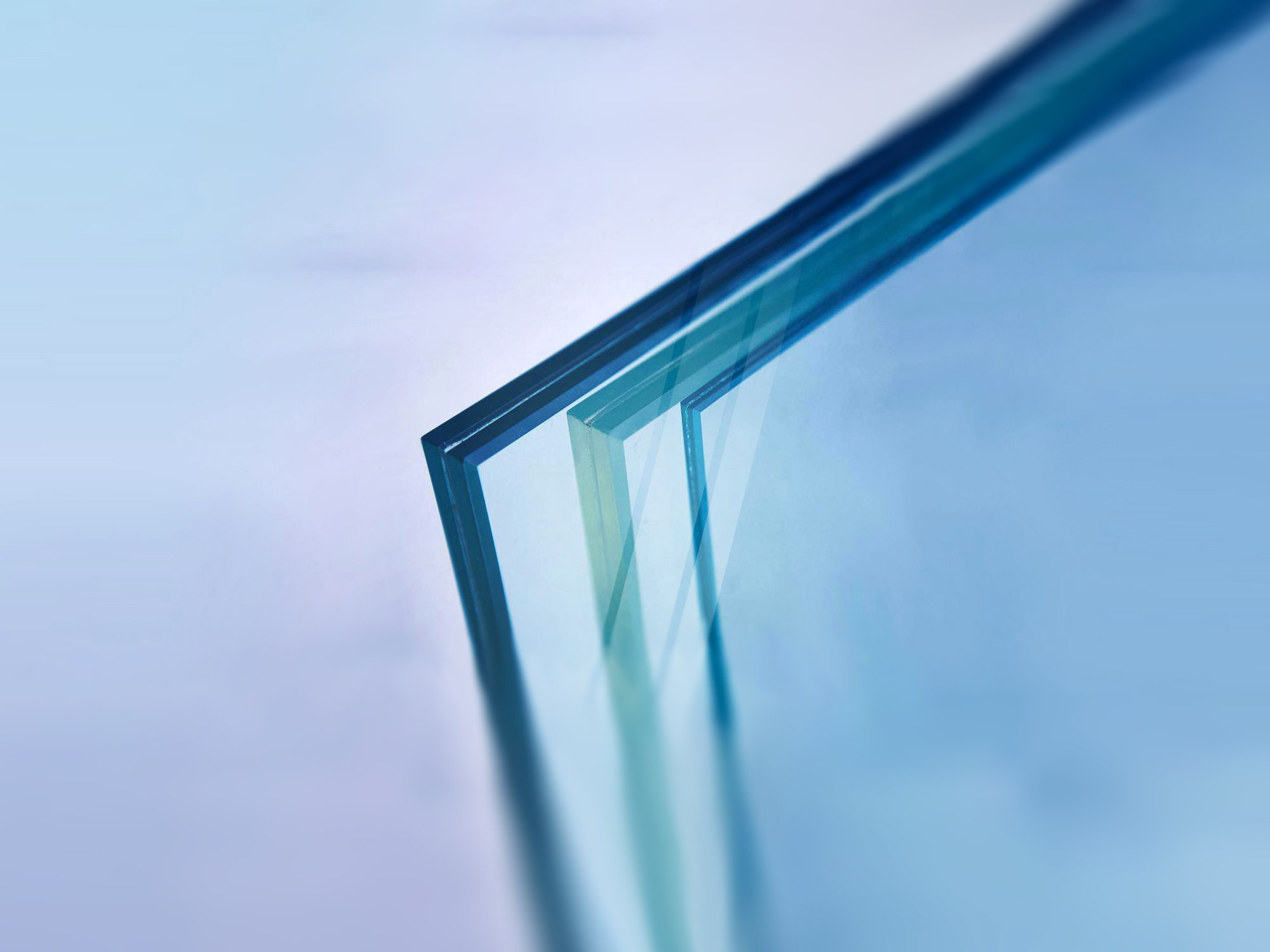

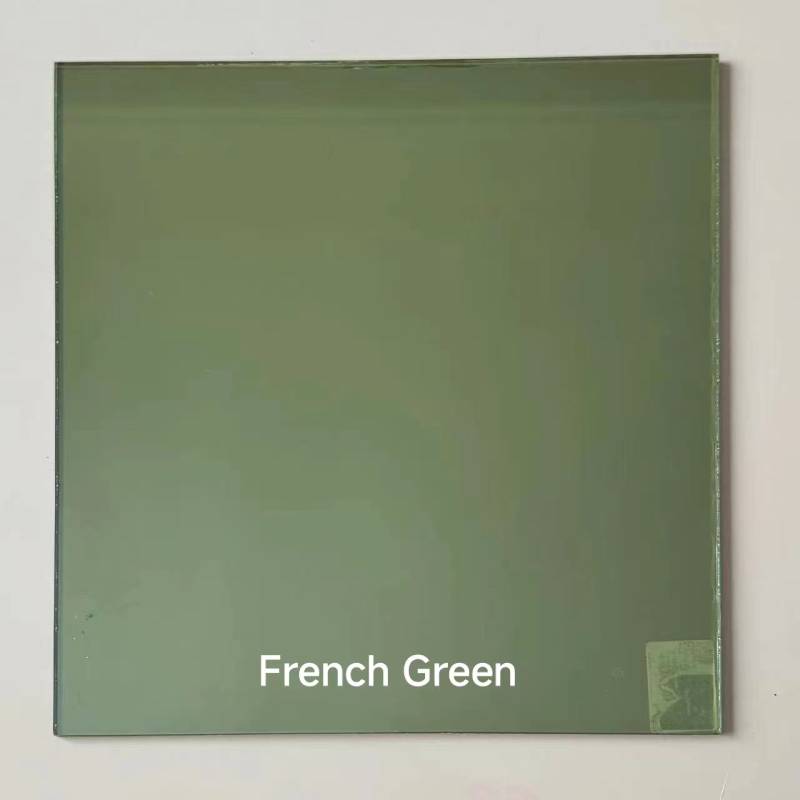

Moreover, Low-E safety glass can be designed to meet various structural and aesthetic requirements. It can be used in windows, facades, and glass partitions, allowing architects to create stunning designs without sacrificing functionality. The glass can be manufactured in different tints and finishes, providing a range of aesthetic options while maintaining energy performance. This versatility makes Low-E safety glass an ideal choice for both modern and traditional architectural styles.

One of the great things about a large starburst mirror silver is its versatility. It can be hung on a wall as a statement piece, placed above a mantle or console table for added drama, or even leaned against a wall for a more casual look. No matter where you choose to place it, the mirror will instantly enhance the aesthetic of the room. Moreover, low e-glass panes offer protection against UV rays, which are known to cause furniture fading and can potentially harm skin

The mirror, on the other hand, symbolizes self-reflection and awareness. When we look into a mirror, we see our own reflection – our strengths, weaknesses, flaws, and beauty. It forces us to confront ourselves and evaluate who we truly are. Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings

The mirror, on the other hand, symbolizes self-reflection and awareness. When we look into a mirror, we see our own reflection – our strengths, weaknesses, flaws, and beauty. It forces us to confront ourselves and evaluate who we truly are. Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings

Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings Similarly, in life, we need to take time to reflect on our actions, thoughts, and feelings door mirror glass. By understanding ourselves better, we can make wiser choices and improve our character. In summary, float glass is a versatile and widely-used product, born out of a groundbreaking manufacturing technique. Its versatility, combined with its inherent qualities, has made it an indispensable material in modern construction, transportation, and technology, contributing significantly to our daily lives. Frosted glass, in itself, is a testament to elegance and privacy, its softened texture diffusing light while maintaining an air of mystery. When infused with vibrant colors, it transforms into a visual spectacle that captivates the eye and ignites the imagination. The interplay of light and color on these surfaces creates a dynamic dance, filling rooms with a soft, ethereal glow that can alter the ambiance dramatically.

door mirror glass. By understanding ourselves better, we can make wiser choices and improve our character. In summary, float glass is a versatile and widely-used product, born out of a groundbreaking manufacturing technique. Its versatility, combined with its inherent qualities, has made it an indispensable material in modern construction, transportation, and technology, contributing significantly to our daily lives. Frosted glass, in itself, is a testament to elegance and privacy, its softened texture diffusing light while maintaining an air of mystery. When infused with vibrant colors, it transforms into a visual spectacle that captivates the eye and ignites the imagination. The interplay of light and color on these surfaces creates a dynamic dance, filling rooms with a soft, ethereal glow that can alter the ambiance dramatically. Moreover, low-E glass contributes to sustainability and energy conservation. By reducing reliance on heating and cooling systems, buildings use less energy, which can lead to a decrease in greenhouse gas emissions. As society becomes increasingly aware of the importance of environmental stewardship, incorporating low-E glass into building designs aligns with global efforts to promote sustainability and combat climate change.

Low-E glass is a type of coated glass that is designed to reduce the transfer of heat through the window. It works by reflecting infrared radiation, which is the type of heat that causes our homes and offices to feel warm in the winter and cool in the summer. By reducing the amount of heat that escapes or enters a building, Low-E glass helps to maintain a comfortable indoor temperature, resulting in significant energy savings.

One of the most appealing aspects of a silver scalloped mirror is its versatility. While it exudes a sense of luxury and refinement, it can harmonize beautifully with various styles. In a minimalistic space, the mirror can serve as a focal point, adding an artistic touch without overwhelming the room. In contrast, in a bohemian setting, it can blend seamlessly with eclectic decor, contributing to a layered and visually stimulating environment.

Another advantage of silver makeup mirrors is their versatility In the realm of architecture and construction, the choice of materials is paramount. One material that has been gaining popularity in recent years is 2mm clear float glass. This type of glass offers a range of benefits that make it an excellent choice for various applications. In the realm of contemporary architecture, one innovation that has significantly reshaped the industry is Low-E (Low Emissivity) glass. This advanced glazing technology, combined with artistic design principles, has paved the way for energy-efficient, aesthetically pleasing, and eco-friendly structures. Glass, a material that has fascinated humankind for centuries, has been transformed into various forms of art and craftsmanship. From delicate glass figurines to intricate stained glass windows, the beauty of glasswork knows no bounds. In recent years, there has been a resurgence in the appreciation for handcrafted glass, with more and more artisans turning to traditional techniques to create stunning pieces that capture the imagination. Float glass, named after the method of its production where molten glass is floated on a bed of molten tin, is renowned for its optical clarity and flatness. The 3mm thickness offers a delicate balance between transparency and strength, making it ideal for various uses. It's lightweight, yet strong enough to withstand everyday wear and tear, ensuring durability in different environments. The Art and Science of Float Glass Manufacturing Silver, known for its exceptional reflective properties, has been used in mirrors for centuries. Its ability to provide a clear, undistorted reflection makes it an ideal material for makeup mirrors. Unlike ordinary mirrors, silver-coated mirrors offer enhanced clarity, allowing users to examine their features minutely, crucial for precise makeup application. The reflective surface of a silver makeup mirror allows one to see every detail, from the subtlest eyeliner stroke to the tiniest speck of mascara, ensuring a flawless finish every time. The process of cutting glass and mirrors to size is an art form in itself

When considering the price of blue reflective glass, it is important to factor in the overall value it can bring to a project. While it may have a higher upfront cost compared to traditional glass options, the aesthetic appeal, energy efficiency, and durability of reflective glass can make it a worthwhile investment in the long run.

Suppliers of silver mirrors come in various sizes and cater to diverse needs. They offer custom-made solutions, from standard rectangular shapes to intricate, artistic designs. Some specialize in antique silver mirrors, replicating the vintage charm of yesteryears, while others focus on modern, minimalist styles. Another advantage of frosted glass is its versatility. It can be installed in various settings, from traditional homes to modern offices, and even in high-end retail spaces. Its ability to diffuse light also makes it practical for lighting fixtures, creating a warm and inviting atmosphere.

Energy Efficiency and Functionality

This quality makes frosted glass ideal for spaces where privacy is essential, such as bathrooms, meeting rooms, and office partitions. It offers a contemporary solution to privacy concerns, allowing for open designs that are both functional and visually appealing.

Insulated Glass Unit Replacement A Comprehensive Guide The 'Clear' aspect of this glass refers to its transparency, ensuring an unobstructed view of the outside world while maintaining the interior comfort. Unlike traditional tinted glasses, Clear Low-E glass doesn't darken or alter the natural light entering the space, thus preserving the aesthetics and ambience of the room. Benefits of Using Low-E Glass The Reflection of Brown Glass In conclusion, brown frosted glass is a practical, stylish, and durable material that offers a range of benefits for both residential and commercial settings. Its ability to provide privacy and light filtering, combined with its warm, earthy tones and low maintenance requirements, make it a popular choice for a wide variety of applications. Whether used in windows, doors, or partitions, brown frosted glass is sure to enhance the look and feel of any space. In conclusion, tinted glass is a practical and stylish solution for enhancing privacy, security, energy efficiency, and aesthetics in both residential and commercial settings. With its ability to combine functionality with beauty, tinted glass has become an increasingly popular choice for architects, designers, and homeowners looking to upgrade their spaces. Whether used in windows, doors, or interior partitions, tinted glass is a versatile material that offers a range of benefits and endless design possibilities. Sustainability is not just a design feature at the Float Glass Center; it's a way of life The beauty of frosted bronze glass lies in its ability to strike a delicate balance between transparency and opacity. Its frosting effect softens the harshness of light, creating a gentle diffusion that adds a sense of intimacy and tranquility. The bronze tint, on the other hand, imparts a warm, earthy glow, evoking the rustic charm of ancient metals while maintaining a modern appeal. Furthermore, the reflective coating on solar control low e glass helps to reduce glare and UV rays, protecting furniture, flooring, and other interior surfaces from fading and damage. This can help to extend the life of your belongings and save you money on replacement costs in the long run

solar control low e glass. But the king knew that the true power of the Silver Scroll Mirror lay not in its ability to reflect physical features but in its capacity to reveal the inner workings of the human heart The Silver Heart-Shaped Mirror

Final Thoughts

Another advantage of frosted brown glass is its versatility

frosted brown glass. It can be used in a variety of ways, from creating a subtle and understated look to making a bold and dramatic statement. Whether used as a standalone feature or in combination with other materials, frosted brown glass adds a touch of elegance and sophistication to any space. The bamboo mirror silver is more than just a decorative object - it is a reflection of our connection to nature, our appreciation for beauty, and our pursuit of harmony in our surroundings. It serves as a reminder to cherish the natural world and to seek balance and serenity in our daily lives. For those who appreciate minimalist aesthetics, our range of clear glass items offers a perfect blend of simplicity and style. From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it

From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it

From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it From transparent glass bottles that add a touch of sophistication to your kitchen to the clean lines of our glass tables, each piece is designed to enhance the ambiance without overpowering it glass for sale. Another key feature of tempered glass is its ability to withstand extreme temperatures Low-E Glass A Revolution in Energy Efficiency

glass for sale. Another key feature of tempered glass is its ability to withstand extreme temperatures Low-E Glass A Revolution in Energy Efficiency Bamboo Mirror Silver

In conclusion, the clear glass mirror transcends its functional role as a mere reflective tool. It serves as a philosophical guidepost, directing us towards clarity, introspection, and transparency. In a world increasingly clouded by illusion and noise, may we all find our own clear glass mirrors to reflect our most genuine selves back to us, and in turn, create spaces of honesty and light for others to flourish within. From a security standpoint, mirrored glass doors offer a level of safety that traditional wood or hollow-core doors cannot match. Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries

Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries

Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries Made from tempered or laminated glass, they are much harder to break through and thus provide an excellent deterrent against forced entries mirrored glass front door. Even if broken, the glass is designed to shatter into small, relatively harmless pieces, reducing the risk of injury. Another benefit of patterned double glazed glass is its sound insulation properties. The two layers of glass can help to reduce noise transmission from the outside, creating a quieter and more peaceful indoor environment. This is particularly useful for buildings located in busy urban areas or near noisy highways.

mirrored glass front door. Even if broken, the glass is designed to shatter into small, relatively harmless pieces, reducing the risk of injury. Another benefit of patterned double glazed glass is its sound insulation properties. The two layers of glass can help to reduce noise transmission from the outside, creating a quieter and more peaceful indoor environment. This is particularly useful for buildings located in busy urban areas or near noisy highways. The production of ultra clear glass involves a specialized process that begins with the selection of raw materials. High-purity silica sand, sodium carbonate, and other essential additives are used, but the critical difference lies in the use of low iron raw materials. By reducing the iron oxide content during the glass-making process, manufacturers can achieve the clear, pristine quality of ultra clear glass.

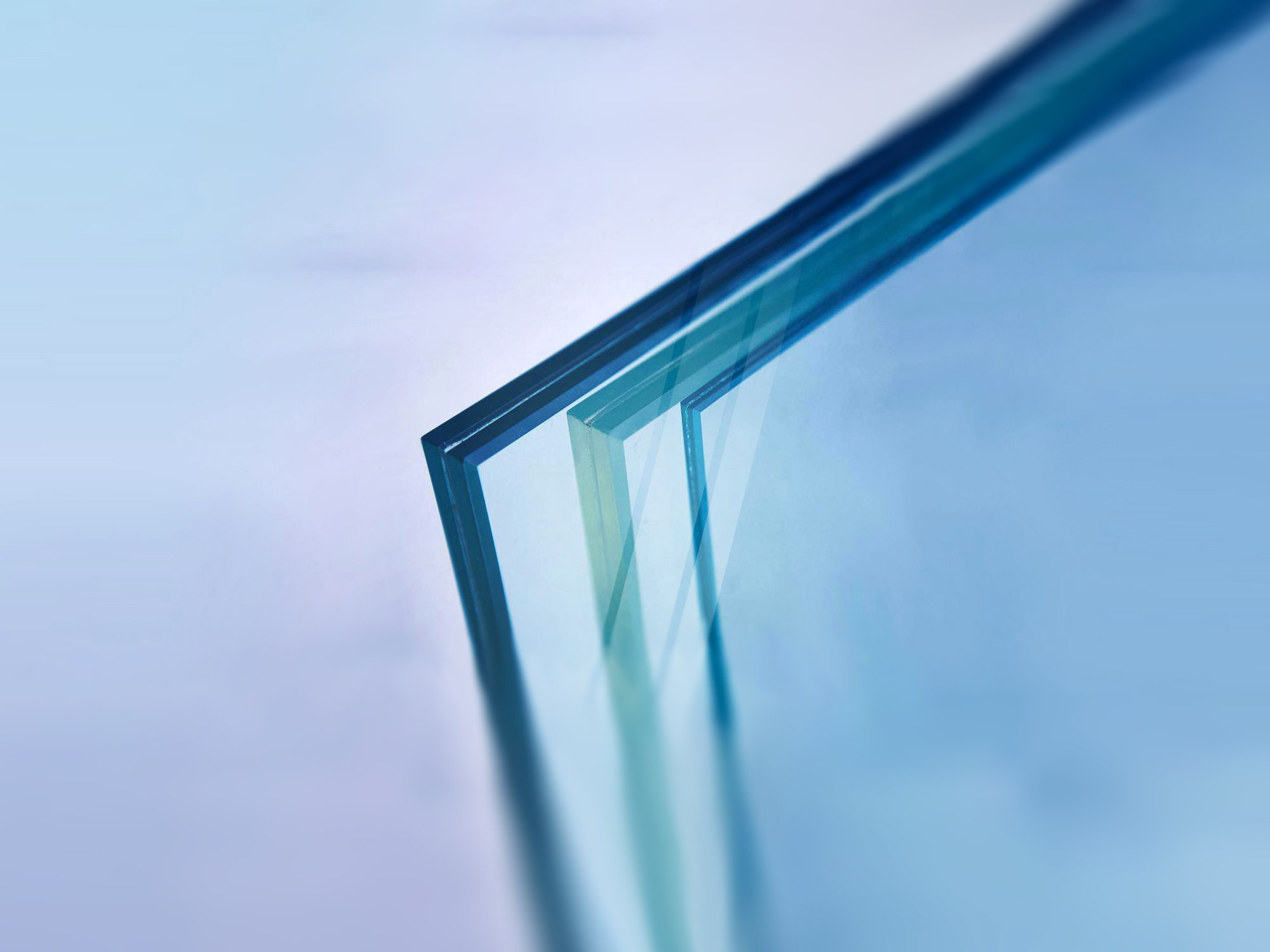

The Bronze Mirror A Glimpse into Antiquity Insulated glass units, also known as double glazing, are a popular option for windows in homes and businesses. They consist of two or more panes of glass separated by a spacer with a sealed air or gas-filled space between them. This design helps to provide better insulation and soundproofing compared to single-pane windows. Float glass, named after the method of its production where molten glass is floated on a bed of molten tin, is renowned for its optical clarity and flatness. The 3mm thickness offers a delicate balance between transparency and strength, making it ideal for various uses. It's lightweight, yet strong enough to withstand everyday wear and tear, ensuring durability in different environments. Insulated glass units, also known as double glazing or thermal panes, are becoming increasingly popular for their energy-saving and soundproofing properties. These units consist of two or more panes of glass separated by a space filled with air or gas, creating an insulating barrier that helps to reduce heat transfer and noise transmission. Leaded Glass, also known as Leaded Light or Leaded Stained Glass, is another classic choice. It involves using lead cames to hold together small pieces of glass, forming a pattern or design. The result is a delicate, lattice-like appearance that adds a touch of vintage charm.

In summary, 4mm float glass is a vital material in various sectors due to its unique properties and adaptability. From enhancing architectural designs to improving product displays, it serves multiple functions while maintaining aesthetic and functional integrity. Its manufacturing process, rooted in precision and quality control, ensures that it meets the high standards required for modern applications. As we continue to innovate and seek sustainable solutions in architecture and design, 4mm float glass will undoubtedly remain a significant player in the industry.