Links:

Conclusion

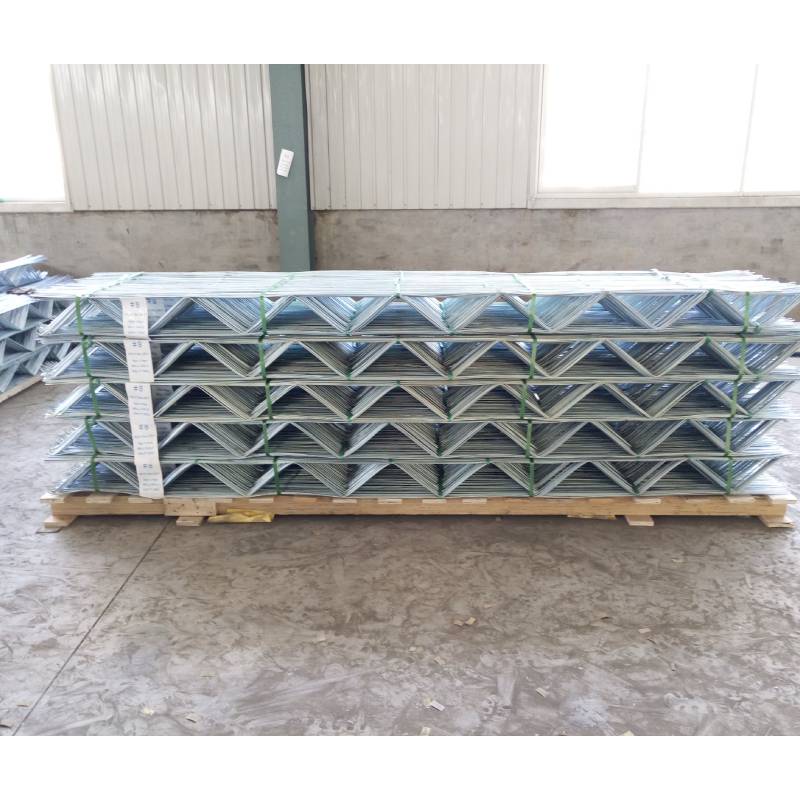

Welded steel panels are becoming increasingly popular in various industries due to their exceptional strength, durability, and versatility. These panels are fabricated by welding together steel sheets, which provides a robust and cohesive structure. The combination of welded joints and steel material creates a product capable of withstanding significant stress and environmental challenges, making it suitable for a wide range of applications.

1. Project Requirements Assess the specific needs of your project. Consider the type of concrete structure you are building and the load it will bear. This will help you determine the appropriate mesh size and gauge.

The production of wire form springs typically involves several key steps

4. Finishing Finally, the springs may receive various finishing treatments, such as shot peening or coating, to improve their durability and resistance to corrosion.

Supporting Sustainability

4. Cost-Effectiveness Although galvanized wire might have a higher upfront cost compared to non-galvanized options, its longevity and lower maintenance needs often translate to long-term savings.

3. Custom Spring Manufacturers

Coil springs are formed by winding wire around a cylindrical shape, creating a helical structure that can compress or extend under load. This design allows them to return to their original shape once the load is removed. There are several types of coil springs, including compression springs, extension springs, and torsion springs, each serving specific purposes and applications.

In the ever-evolving field of construction, the integration of innovative materials has significantly transformed the methodologies used in building design and structural integrity. Among these advancements, the use of metal mesh in concrete has emerged as a groundbreaking approach that enhances both the strength and durability of concrete structures. This article explores the benefits, applications, and implications of using metal mesh in concrete.

Types of Wire Lath

In summary, spacers for reinforcing mesh are a critical component in construction that significantly influences the strength, durability, and safety of concrete structures. Understanding the different types of spacers and their appropriate applications is essential for engineers and builders alike. Properly selected and installed spacers can lead to more resilient structures, capable of withstanding the test of time and the forces of nature. Therefore, investing in high-quality spacers is not just a matter of compliance; it's a commitment to building safer, stronger, and more reliable structures for the future.

- Design Documentation Before starting construction, it is essential to have detailed design documentation that outlines the anchoring system's requirements. This ensures that the chosen method is suitable for the specific building conditions.

Understanding Chicken Wire Mesh

In conclusion, investing in heavy-duty tomato cages can transform your gardening experience. With their strength and durability, these cages are essential tools for anyone serious about growing healthy, productive tomatoes. By providing the support your plants need, you'll not only enhance their growth but also enjoy the delicious rewards of your hard work come harvest time. Therefore, when planning your garden, don’t overlook the importance of a good tomato cage – it might just be the key to your gardening success!

5. Customer Support A good supplier provides excellent customer support, assisting with inquiries about product specifications, installation, and compliance with local building codes.

Importance of Masonry Tie Spacing

Benefits of Spring Steel Coils

- Support Tall Arrangements For tall centerpieces, florist wire can help stabilize heavy stems, ensuring that your arrangements remain upright and impressive.

Benefits of Cold Drawn Steel Bars

What Are Brick Ties?

Where to Buy Metal Springs

Conclusion

Conclusion

In conclusion, white grid wall panels are a multifunctional and stylish solution for enhancing both residential and commercial spaces. Their versatility, ease of installation, and adaptability make them an excellent choice for anyone seeking to refresh their interiors. As design trends continue to evolve, these panels will undoubtedly remain a popular choice for those looking to create visually appealing and functional environments. Whether you're a homeowner, a designer, or a business owner, incorporating white grid wall panels into your space promises to bring a touch of contemporary elegance and practicality.

Wire metal grids, a fascinating intersection of engineering, art, and industrial design, are utilized across numerous sectors, owing to their versatility and robustness. Constructed from an array of interconnected metal wires, these grids can be tailored in a variety of configurations, dimensions, and materials, making them ideal for a plethora of applications.

6. Local Machine Shops

The Elegance of Black Grid Artwork for Wall Decor

Applications Beyond Poultry

Furthermore, metal is a durable and versatile material. Unlike plastic or wood, which may deteriorate over time, metal supports often withstand the test of time, resisting rust and corrosion, especially if treated with weather-proof coatings. This long-lasting nature means that gardeners can invest in quality metal supports that enhance their gardens for years to come.

metal garden plant supports

Cost-Effective Solution

Historically, walls have been a fundamental element of human civilization. From ancient forts to modern skyscrapers, walls protect, divide, and connect. Stone, as a building material, symbolizes durability and resilience. When used in structures, stone walls represent not only physical barriers but also a commitment to longevity and stability. Among the ancient Romans, for instance, stone walls were an essential part of their fortifications, reflecting the strength and authority of the empire. Over centuries, this has evolved into modern engineering practices where stone is often incorporated with other materials, showcasing the adaptability of these ties over time.

One common type of cavity wall tie is made from dissimilar materials, such as stainless steel, galvanized steel, or plastic. Stainless steel ties are often preferred due to their resistance to corrosion, making them suitable for environments with high moisture levels. Galvanized steel ties, coated with zinc, also offer some level of protection against rust but may not perform as well in highly corrosive environments. Plastic ties are lightweight and non-corrosive, making them a good option for low-load applications, although they may lack the strength of metal ties.

2. Improved Resistance to Lateral Forces Buildings are often subjected to lateral forces from wind and seismic activity. Horizontal joint reinforcement increases resistance to these forces, helping to maintain the alignment and stability of the structure. This reinforcement is especially vital in areas prone to earthquakes, where lateral movement can lead to catastrophic damage if not adequately mitigated.

Extension springs are versatile components widely used in various applications across industries, and those equipped with extended hooks offer even more flexibility in their use. The design of an extension spring with extended hooks allows for a broader range of functionality, making them an essential element in mechanical engineering and manufacturing.

Moreover, the wire can be employed to build cages or frames for vegetables and other plants. For instance, tomatoes benefit greatly from being supported off the ground to avoid rot and make harvesting easier. Crafting a simple tomato cage using 2mm galvanised wire allows for optimal air circulation and sunlight exposure, leading to healthier plants and better yields.

2mm galvanised garden wire

Emerging Trends in the Market

Enhanced Security

What is Stainless Chicken Wire?

Conclusion

1. Enhanced Structural Integrity Horizontal joint reinforcement significantly improves the structural integrity of brick walls. Masonry is inherently strong in compression but weak in tension. The addition of reinforcement allows the bricks to work together more effectively under various load conditions, significantly reducing the risk of cracking and structural failure.

In summary, cavity wall ties play a crucial role in the stability and efficiency of cavity wall constructions. From traditional metal ties to innovative plastic and composite options, these connectors ensure that the building's outer and inner walls work cohesively. Choosing the appropriate wall tie type depends on various factors, including structural requirements, environmental conditions, and energy efficiency considerations. Understanding the different types of cavity wall ties allows builders and architects to make informed decisions that will contribute to the longevity and performance of their structures.

Galvanised wire is renowned for its durability and resistance to corrosion, making it an ideal choice for a variety of applications in both domestic and commercial settings. Among the different thicknesses available, 4mm galvanised wire stands out due to its unique blend of strength, versatility, and longevity.

Understanding Stucco Corner Beads A Comprehensive Guide

As the caterpillar matures, it enters the pupal stage—an often overlooked yet crucial phase of its life cycle. Here, it undergoes a radical transformation, encapsulated in a chrysalis. This stage represents a time of reflection, growth, and change. In our own lives, moments of introspection often precede significant breakthroughs. Like the Wall Ties Butterfly, we too must embrace periods of uncertainty and stillness, where we can gather strength for the journey ahead. The process of transformation is not always visible; often, it requires patience and faith in what lies beneath the surface.

wall ties butterfly

Sustainability also plays a role in the appeal of flexible sign holders. By allowing businesses to renew signage easily, these holders can reduce paper waste and minimize the environmental footprint associated with constant printing. Companies can invest in high-quality signage materials that are reusable, promoting a more eco-friendly approach to communication.

5. Robotics In robotic applications, these springs are vital for motion control and ensuring that components return to their default positions after activation, thus enabling precise movements.

Another significant advantage of these panels is their aesthetic appeal. Galvanized steel has a shiny, metallic finish that can enhance the look of any project. This quality has led to their increasing popularity in architectural designs, where they are often used as decorative elements in modern buildings. Whether as railing systems, privacy screens, or facades, galvanized steel mesh panels add a contemporary touch to a wide range of settings while maintaining functionality.

galvanized steel mesh panels

Types of Lath Stucco Mesh