Links:

-

Architects and designers often use reflective blue glass to create a sense of luxury and sophistication in their projects

1. Architectural Use One of the primary applications is in the architectural field. 4mm float glass is extensively used in windows, glass doors, and partitions due to its aesthetic appeal and functional performance. It enhances natural lighting while providing insulation and energy efficiency in buildings.

4mm float glass

One of the key advantages of bronze tinted mirror glass is its ability to reflect light while maintaining a level of opacity. This makes it an ideal choice for areas where privacy is important, such as bathrooms or dressing rooms. The bronze tint adds a warm, inviting glow to the space, creating a cozy and intimate atmosphere.

Float glass video offers several key advantages over traditional VR methods Environmental consciousness also plays a significant role in today's supplier selection process. Leading 2mm float glass suppliers are increasingly adopting sustainable practices, including the use of recycled materials and energy-efficient manufacturing techniques. They recognize the impact of their operations on the environment and strive to minimize it, offering clients peace of mind that their choices align with eco-friendly values. In the realm of interior design and architecture, mirror glass adhesive enables creative freedom. Designers can specify mirrors in areas where traditional fasteners would be unsightly or impractical, such as in sleek, modern settings where the emphasis is on clean lines and minimalism. Moreover, the adhesive allows for the creation of bespoke mirrored features like wall art or decorative panels with intricate designs that would otherwise be challenging to achieve securely and attractively. In today's fast-paced world, safety and style are two of the most important factors that people consider when it comes to their homes and offices. One material that has proven to be a game-changer in both these areas is laminated mirror glass. One of the key features of float glass is its ability to 'float' on molten metal during production. This method results in a consistently smooth and flat surface on both sides, making it ideal for applications where precision and uniformity are crucial. The float process also imparts excellent thermal stability, ensuring minimal expansion or contraction under varying temperatures.

(1) Glass installation

The national tempered glass industry has shown a trend of continuous growth in recent years. According to statistics, in March 2024, the industry's monthly output reached 50.659,000 square meters, an increase of 15.4% year-on-year, showing that the industry is in a positive growth cycle. This growth is mainly due to the rapid development of the construction industry, automobile manufacturing and new energy industries. With the acceleration of the urbanization process and the improvement of people's requirements for the quality of the living environment, the demand for tempered glass in the construction industry continues to grow. At the same time, the rapid rise of the new energy vehicle market has also brought new growth points to the tempered glass industry. In addition, with the continuous progress of science and technology and the intensification of market competition, enterprises have increased research and development investment, promote technological innovation and product upgrades to meet the changing needs of the market.

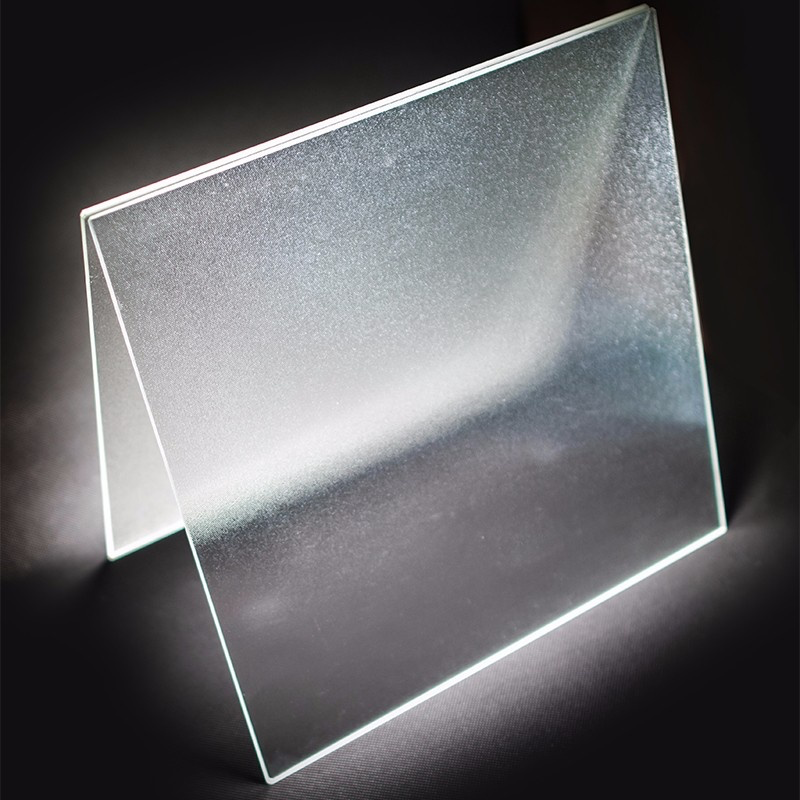

One of the main advantages of acid etched glass panels is their versatility. They can be used in a variety of applications, from doors and windows to partitions and shower enclosures. The frosted finish of the glass provides privacy without completely blocking out light, making it an ideal choice for spaces where natural light is a priority. In addition to quality, it is important to consider the range of glass products and services offered by a glass supplier. A comprehensive glass supplier should be able to provide custom-cut glass, as well as a variety of glass finishes and textures to meet the aesthetic requirements of different projects. They should also offer services such as glass installation and maintenance to ensure that customers have access to full support throughout the life of their glass products

glass supplier. Moreover, the aesthetic appeal of Low-E 366 Argon glass should not be overlooked. It allows ample natural light to filter in while maintaining privacy and blocking unwanted glare. This harmonious blend of aesthetics and practicality makes it a preferred choice for architects and designers. The history of French green float glass is deeply intertwined with the industrial revolution and the relentless pursuit of architectural aesthetics. In the mid-20th century, as technology advanced, so did the techniques for producing larger, clearer, and more visually striking glass panes. This particular shade of green was achieved through the addition of iron oxide to the glass mixture during production, which not only provides the distinctive color but also filters out certain wavelengths of light, reducing solar heat gain and making it an energy-efficient choice for buildings. 1. Windows Grey low E glass is commonly used in windows to improve energy efficiency, reduce heat loss in winter and heat gain in summer, and provide privacy. The process of manufacturing tempered glass in these factories begins with float glass, which is heated to approximately 600°C and then rapidly cooled. This rapid cooling induces compressive stress on the surface of the glass, while the core remains under tension. If the glass breaks, it shatters into small, harmless granules instead of sharp, jagged pieces, significantly reducing the risk of injury. The reflective property of this glass serves a dual purpose. Firstly, it reflects a significant amount of sunlight, thereby reducing the heat ingress into the building, which in turn aids in energy conservation and contributes to sustainable architecture. Secondly, it maintains privacy while still allowing light to pass through, creating an ambiance that is both bright and secluded.

First, introduction: The vigorous development of tempered glass industry

4. Environmental Sustainability By reducing energy consumption, Low-E glass helps to reduce greenhouse gas emissions and combat climate change. The Enchanting Charm of Milky Frosted Glass One of the most significant advantages of using mirror glass adhesive is its durability. Once cured, it can last for many years without losing its grip. This reduces the need for replacements or repairs due to failed mounting methods. Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room

Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room Additionally, because it forms a tight seal, it contributes to the overall integrity of the mirror by helping to prevent cracks or breaks that might occur due to minor impacts or pressure changes within the room mirror glass adhesive.

mirror glass adhesive. Benefits of Choosing 6mm Frosted Glass

Final Thoughts

* Wear gloves Frosted glass adhesive may contain chemicals that can irritate your skin, so it's a good idea to wear gloves when handling it. Installation costs should not be overlooked when calculating the total expenditure. Frosted glass often requires professional fitting to ensure it is securely placed and properly sealed, especially in areas where weather resistance is needed. The complexity of the installation, including access to the site and the need for specialized equipment, will impact the installation fee. Glazed tempered glass is a type of safety glass that has been treated to increase its strength and durability. It is commonly used in a variety of applications, including windows, doors, partitions, and furniture. One of the key advantages of glazed tempered glass is its ability to withstand high temperatures without shattering, making it an ideal choice for applications such as cooktops, fireplaces, and industrial ovens. Crafted with precision from high-quality aluminum alloy, this mirror embodies durability and resilience. Aluminum, known for its resistance to corrosion and lightweight nature, ensures that the frame remains steadfast and robust over time. The sleek and slender profile of the frame is a testament to contemporary design, seamlessly blending into various decors, from minimalist chic to industrial elegance. Float glass is primarily composed of about 70% silica (sand), 13% soda ash (sodium carbonate), and 12% limestone (calcium carbonate), with small amounts of other materials added for specific properties such as color or durability. Its uniform thickness and optical clarity make it ideal for a wide range of uses. The Silver Mantle and the Mirror In residential settings, colored frosted glass doors and windows offer a touch of privacy without sacrificing style. They filter natural light, creating a soothing atmosphere while obscuring prying eyes. In bathrooms or bedrooms, they add a dash of personality while maintaining a sense of intimacy. In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space

In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space

In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space In kitchens, they can be used for backsplashes or cabinet doors, introducing a pop of color without overwhelming the space colored frosted glass.

colored frosted glass. 1. Melting The process begins with melting raw materials, primarily silica, soda ash, and limestone, in a furnace at around 1,700 degrees Celsius.

Another advantage of ultra clear glass is its durability Apart from privacy, tinted glass also offers several aesthetic benefits

tinted glass colors. It can add a touch of style and sophistication to any room, making it an excellent addition to modern interiors. The wide range of colors and shades available ensures that you can find a tint that perfectly matches your personal taste and decor. Whether you prefer a subtle, neutral tone or a bold, vibrant color, there is a tinted glass option to suit your needs.

tinted glass colors. It can add a touch of style and sophistication to any room, making it an excellent addition to modern interiors. The wide range of colors and shades available ensures that you can find a tint that perfectly matches your personal taste and decor. Whether you prefer a subtle, neutral tone or a bold, vibrant color, there is a tinted glass option to suit your needs. High strength: photovoltaic glass after special treatment, has high mechanical strength and impact resistance, can withstand wind pressure, snow, hail, throwing stones and other external and thermal stress impact, not easy to crack and crack.

The float glass process was developed in the mid-20th century by Sir Alastair Pilkington, revolutionizing the glass industry. Prior to this method, glass was produced using labor-intensive techniques that often resulted in irregular thickness and surface imperfections. The float process employs a simple yet ingenious technique where molten glass is floated on top of molten tin, creating a perfectly flat surface as the two materials interact. This unique combination allows for the production of glass sheets with unparalleled uniformity and clarity.

Silver Butterfly Mirror A Reflection of Beauty and Transformation

Translucent frosted glass is a versatile material that can bring beauty and functionality to any space. Its unique characteristics make it a popular choice for both residential and commercial applications.

Another advantage of toughened plain glass is its resistance to thermal stress. This property makes it ideal for use in areas with extreme temperature fluctuations, such as shower enclosures or glass doors in cold climates. The ability to withstand thermal stress without breaking or cracking adds to the longevity of toughened plain glass. The sale of Low-E glass is not just about efficiency; it also brings an element of style and sophistication to any property. With its clear, sleek appearance, it enhances the visual appeal of both residential and commercial buildings. It allows ample natural light to filter in, creating a bright and inviting atmosphere, while still maintaining privacy. In addition to its technical excellence, the float glass centre is also committed to sustainability. The facility uses energy-efficient manufacturing processes and recycles glass waste to minimize its environmental impact. By investing in research and development, the centre is constantly exploring new ways to make glass production more sustainable and environmentally friendly. The demand for 5mm reflective glass has been on the rise in recent years, driven by its versatile applications in various industries. This article aims to provide a comprehensive analysis of the factors influencing the price of 5mm reflective glass and explore future trends in this market.

The development status of photovoltaic glass industry

Gold Plus Float Glass Price A Comprehensive Analysis While it's possible to replace an IGU yourself, professional installation is highly recommended for several reasons Low e-glass, short for low emissivity glass, is coated with a thin layer of metal or metal oxide. This microscopically thin coating works wonders in reflecting infrared light, which is responsible for carrying heat. In practical terms, this means that during the warmer months, low e-glass keeps interior spaces cooler by reflecting solar heat away from the building. Conversely, in colder weather, it prevents indoor heat from escaping through the windows, effectively reducing the need for excessive heating.4. Easy Maintenance Cleaning frosted glass is generally straightforward. A mild detergent solution and a soft cloth are often all that is needed to maintain its appearance. This ease of maintenance is particularly beneficial in environments like commercial spaces where hygiene is crucial.

3. **Frame Material** The frame material of the IGU can affect its durability, maintenance requirements, and appearance. Common options include vinyl, aluminum, and wood. Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep

Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep

Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep Vinyl frames are generally low-maintenance and durable, while wood frames offer a classic look but require more upkeep insulated glass unit replacement. The selection process for reflective glass suppliers is multifaceted, involving considerations of quality, pricing, delivery timelines, and customer service. High-quality reflective glass should exhibit consistent optical properties, durability, and resistance to scratches and corrosion. Pricing, while crucial, should not overshadow the importance of quality and reliability. A supplier that offers competitive pricing but fails to deliver on time or provides subpar material can lead to project delays and additional costs.

insulated glass unit replacement. The selection process for reflective glass suppliers is multifaceted, involving considerations of quality, pricing, delivery timelines, and customer service. High-quality reflective glass should exhibit consistent optical properties, durability, and resistance to scratches and corrosion. Pricing, while crucial, should not overshadow the importance of quality and reliability. A supplier that offers competitive pricing but fails to deliver on time or provides subpar material can lead to project delays and additional costs.