Handheld sewing machines stand out for their portability and lightweight design, making them ideal for sewing on the go. However, not all handheld machines are created equal. Heavy duty models are specifically engineered to handle thicker, tougher fabrics such as canvas. Traditional sewing machines might struggle with these materials, often leading to skipped stitches or even damage to the machine itself. With a heavy duty handheld sewing machine, you can work confidently with canvas and other robust fabrics.

One of the most notable features of automatic computerized sewing machines is their ability to store and recall stitch patterns. Users can select from a vast library of predefined stitches, ranging from simple straight stitches to complex decorative designs. With just the press of a button, users can switch between patterns, making it possible to create detailed projects without the need for manual adjustments. This versatility not only saves time but also encourages creativity by allowing users to experiment with different designs effortlessly.

3. Thread the machine Thread the two needles separately using two spools of thread. Place each spool on a separate spool pin and thread them through the machine following the threading guide

how to use the double needle in sewing machine. Make sure to thread each needle correctly to avoid tangles and breakages.

In addition to garment making, the single needle lock stitch has applications in quilting. Quilters often rely on this stitch to piece together layers of fabric and batting, providing the necessary durability and integrity. Home decor projects like pillow covers, curtains, and table linens also benefit from this stitch for a clean and professional finish.

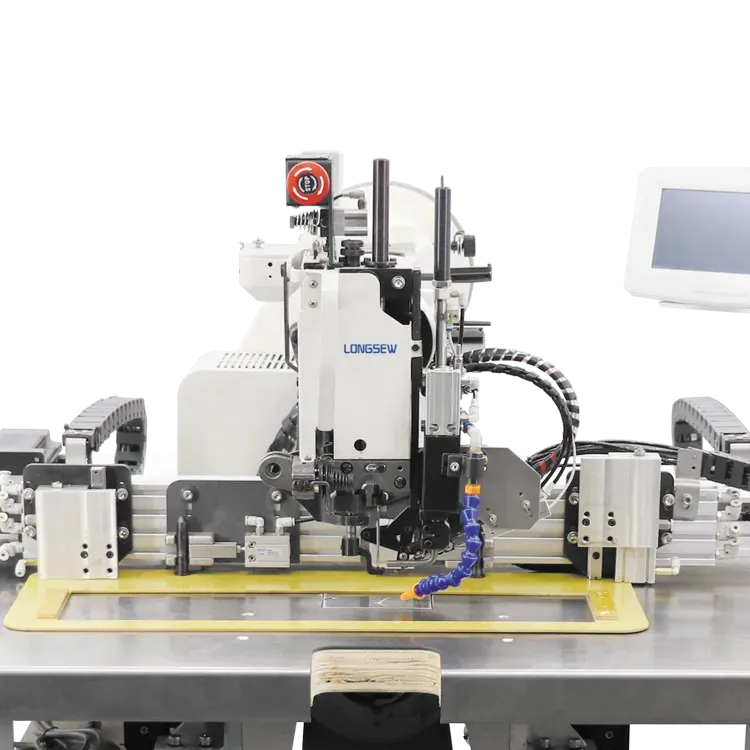

In conclusion, auto sewing represents a groundbreaking shift in the textile industry, offering notable benefits such as increased efficiency, consistency, and cost savings. While challenges exist, including workforce displacement and initial investment costs, the potential for innovation and sustainability is immense. As the industry adapts and evolves, the collaboration between technology and human skill will ultimately forge a path toward a more efficient and sustainable textile production landscape. Embracing this change could be the key for companies to thrive in a rapidly changing market.

The Double Needle Walking Foot Sewing Machine An Essential Tool for Creatives

In the world of sewing, there are countless tools and machines designed to facilitate the creative process. Among these, the twin needle sewing machine stands out as a versatile and valuable option for both seasoned sewists and beginners alike. This unique machine offers a range of capabilities, allowing users to create intricate designs while enhancing the quality of their projects.

1. Increased Efficiency The ability to sew through thick materials without jamming or breaking needles significantly increases productivity. Heavy duty motors enable seamstresses to complete projects quicker and with more confidence in the machine's performance.

The lockstitch machine is a versatile tool used in various sewing projects, from clothing and accessories to home decor and upholstery. It is suitable for sewing different types of fabrics, from delicate silk to heavy denim, making it a popular choice among both professional sewers and hobbyists.

Benefits of Using Cylinder Arm Sewing Machines

5. Bed Size and Construction

What is an Overlocker in Sewing?