Links:

5. Pricing and Availability Competitive pricing without compromising quality is essential. Additionally, evaluate suppliers on their ability to provide consistent supply, especially for businesses that require large volumes of HEC.

Applications of HEC Cellulose

Applications in the Pharmaceutical Industry

Moreover, HPMC manufacturers are key players in the global supply chain. They must navigate market fluctuations, meet the needs of various industries, and respond to emerging trends. For example, the rising demand for plant-based and gluten-free products has led manufacturers to innovate and diversify their offerings to cater to these niches.

- Sustainability As a biodegradable substance, HPMC aligns with the growing demand for sustainable ingredients in product formulations, contributing to environmentally friendly practices.

Understanding the HPMC address involves knowledge of the manufacturing plant's location, the suppliers, and the certifications they hold. This information is crucial for companies seeking to ensure the quality of their products and maintain compliance with regulatory requirements. Traceability is an essential part of any supply chain, not just for accountability but also for managing recalls, should a safety issue arise.

Characteristics of Quality HPMC Suppliers

Where to Buy Cellosize Hydroxyethyl Cellulose

The Importance of Hydroxy Methyl Cellulose in Modern Applications

Moreover, HEC's thickening properties can exhibit shear-thinning behavior, which is highly advantageous in formulations. In shear-thinning systems, viscosity decreases under applied stress or shear; thus, products can be easily applied while maintaining stable viscosity during storage. This attribute is beneficial in various fields, particularly in paints and coatings, where easy application and uniformity are crucial.

Additionally, HPMC is utilized in ophthalmic preparations, where it acts as a lubricant to relieve dry eyes. Its non-toxic nature and compatibility with various pharmaceutical excipients allow for a wide range of applications in drug delivery systems.

In construction, HPMC is widely used in cement-based materials such as mortars and plasters. It enhances workability, water retention, and adhesion. The physical properties of HPMC allow for improved application of these materials, ensuring durability and longevity. Its role in this sector demonstrates how versatile HPMC is, transcending traditional boundaries.

The Importance of HPMC Suppliers in the Pharmaceutical Industry

The degree of substitution of hydroxyethyl groups along the cellulose chain significantly affects the solubility of HEC. Higher degrees of substitution generally lead to an increased solubility due to a greater number of hydrophilic sites, enhancing the interaction with water. However, there is a balance; excessively high substitution levels may lead to instability and a decrease in performance due to increased viscosity.

Selecting the Right HPMC Grade

5. Technological Advancements Innovations in polymer chemistry and processing techniques can influence RDP prices. New formulations that enhance performance or reduce production costs can lead to competitive pricing strategies. Companies that invest in research and development may be able to offer superior products at a more attractive price point.

In addition to large manufacturers, there are also several smaller and specialized companies that focus on niche markets within the RDP industry. These companies can offer unique formulations and personalized services that larger manufacturers may not provide. The competitive landscape fosters innovation, leading to the development of new products that can address specific industry challenges.

4. Improved Wetting and Dispersing Properties HPMC enhances the wetting ability of detergents, allowing them to spread quickly and evenly across surfaces. This improved wettability facilitates more effective stain removal, as the detergent can penetrate fabrics or surfaces more efficiently.

Another critical benefit of using redispersible emulsion powder is its contribution to water resistance. This makes it an excellent choice for exterior applications, such as façade coatings and balcony systems. By improving water repellency, REP helps prevent damage caused by water ingress, effectively contributing to the longevity and durability of construction components.

redispersible emulsion powder

What is HPMC?

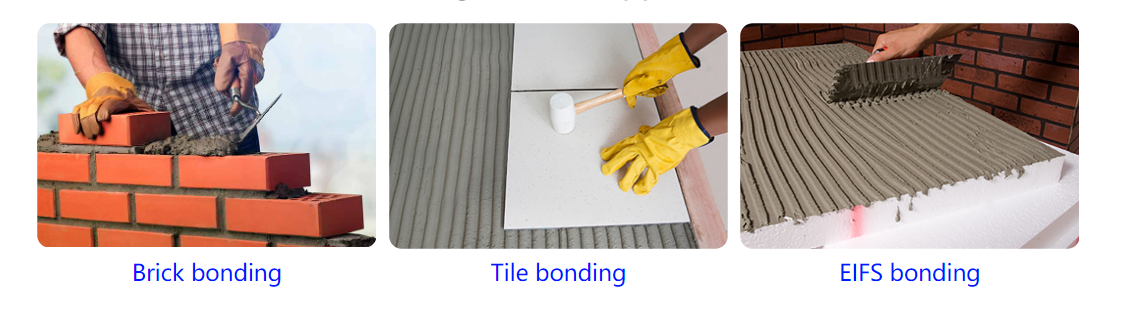

Understanding Mortar Bonding Additives Enhancing Performance and Durability

In addition to technology consulting, HPMC Solutions LLC prides itself on its project management capabilities. Every successful project begins with meticulous planning and execution, and the firm excels in both these aspects. By utilizing proven methodologies and frameworks, HPMC Solutions LLC ensures that projects are delivered on time, within scope, and aligned with budgetary constraints. Their team of project managers works closely with clients to establish clear objectives, monitor progress, and address any issues that may arise during the project lifecycle.

hpmc solutions llc

1. Construction Industry MHEC is extensively employed as a thickener and binder in cement-based products such as tile adhesives, stuccos, and mortar. Its water retention properties ensure that these materials remain workable longer, allowing for improved adhesion and reduced cracking.

In addition to its use in solid dosage forms, HPMC is used in ophthalmic preparations. Its viscosity and film-forming properties enable it to retain moisture in eye drops, providing relief from dry eyes and enhancing comfort. HPMC's biocompatibility further supports its use in various medical applications, including wound dressings and drug delivery systems.

hydroxypropyl methyl cellulose

In conclusion, hydroxypropyl methylcellulose is a versatile and essential polymer that plays a crucial role in various sectors, including pharmaceuticals, food, construction, and cosmetics. Its unique properties, such as solubility in cold water, thickening ability, andnon-toxic nature, contribute to its widespread utilization. As industries continue to prioritize sustainability, HPMC is poised to remain a vital ingredient in the development of innovative and eco-friendly products. Its adaptability and functionality make it a lasting asset in modern applications, highlighting the importance of cellulose derivatives in today’s manufacturing landscape.

Composition and Production

In summary, HPMC stands for Hydroxypropyl Methylcellulose, a versatile and effective polymer with a myriad of applications across various industries. Its unique chemical properties allow it to serve as a thickening agent, binder, and stabilizer in pharmaceuticals, food, cosmetics, and construction materials. As industries continue to seek more efficient and effective ingredients to improve product formulations, HPMC will undoubtedly remain a vital component in innovative solutions. Whether you're taking a medication, enjoying a gluten-free pizza, or applying a moisturizer to your skin, HPMC plays an essential role in enhancing the quality and effectiveness of numerous products in our daily lives.

The Versatility of Hydroxypropyl Methylcellulose (HPMC) Powder

The pH of the solution can also influence the solubility of HEC. Typically, HEC exhibits good solubility in neutral to slightly alkaline environments. Extreme pH levels, whether acidic or alkaline, can lead to hydrolysis of the polymer backbone or side groups, thus affecting its solubility and functionality.

Conclusion