Links:

-

In recent years, instrumental techniques have gained prominence for their speed and precision. Ion chromatography, for instance, separates and quantifies ions based on their affinity to a resin within a chromatographic column. The sulfate ions are eluted and detected, typically by conductivity or UV detection after reaction with a reagent that enhances their detectability. The area under the peak in the chromatograph is proportional to the concentration of sulfate, which can then be translated to TiO2 content through appropriate calculations. Titanium Dioxide Rutile (TiO2) Emulsion in Latex Paints Manufacturing

- Candies and sugar-based treats

- O'Brien, W.J. (1915). The Study of Lithopone. J. Phys. Chem. 19 (2): 113–144. doi:10.1021/j150155a002..

- Market Breakup by Region In the food and pharmaceutical sectors, TIO2 is utilized as a food coloring agent and a tablet coating due to its non-toxic nature and high purity. We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications

Basic Information:

Market Trends and Factors Contributing to Affordability

Lithopone is an inorganic white pigment, obtained from co-precipitation of Zinc sulfide (ZnS) and Barium sulfate (BaSO4). As a white pigment, it acts as a cost-effective alternative for TiO2. Some of the properties of Lithopone include high brightness and performance under UV exposure. Lithopone requires less wetting agent to achieve optimum wetting of its surface. It is commercially graded on the basis of amount of ZnS. Its grades include 28%, 30%, and 60% ZnS. As a comparatively inexpensive white pigment, Lithopone is presently used in various paint formulations, road marking paints, jointing compounds, and putties.

Food quality

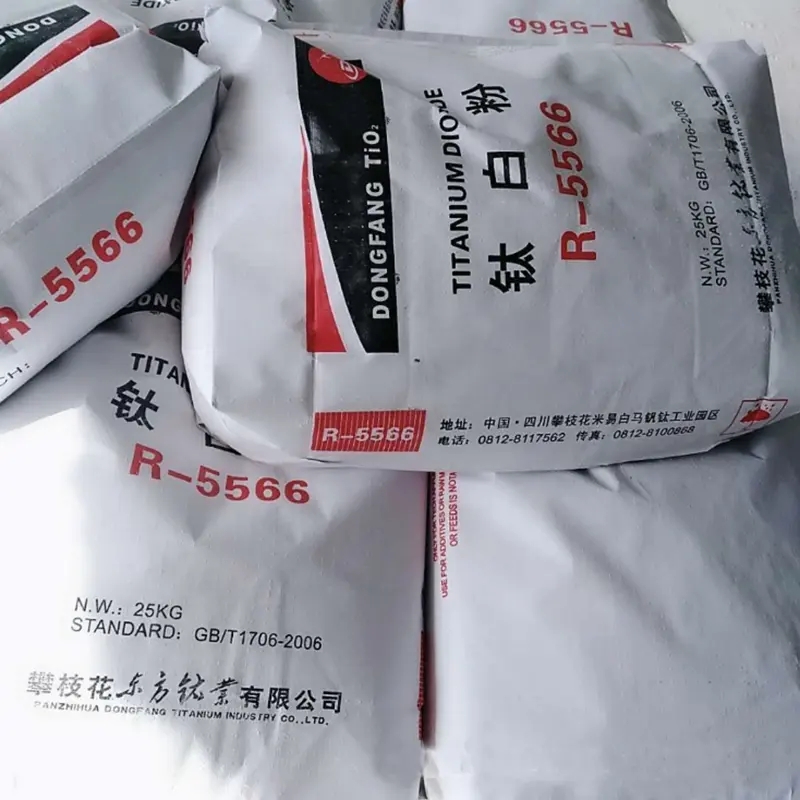

china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth. Titanium dioxide, with the chemical formula TiO2 and an internationally recognized CAS number of 13463-67-7, is a widely used pigment in various industries due to its exceptional optical properties and high refractive index. As a key player in the global market, China has emerged as a dominant force in the production and supply of this crucial material.

china rutiletitanium dioxide manufacturer. Environmental concerns have become a major issue in recent years, as the industry's rapid expansion has put pressure on natural resources and ecosystems. To address these challenges, Chinese authorities have implemented stricter environmental regulations and encouraged the adoption of cleaner production technologies. These efforts have helped to improve the industry's environmental performance and ensure sustainable growth. Titanium dioxide, with the chemical formula TiO2 and an internationally recognized CAS number of 13463-67-7, is a widely used pigment in various industries due to its exceptional optical properties and high refractive index. As a key player in the global market, China has emerged as a dominant force in the production and supply of this crucial material.

For the Year 2020

Furthermore, factory price Tio2 suppliers offer a wide range of Tio2 products to cater to different industry needs. Whether manufacturers require Tio2 for paint, plastics, or cosmetics, these suppliers can provide the right type of Tio2 that suits their specific application. This flexibility in product offerings allows manufacturers to find the most suitable Tio2 for their products. The ceramic and glass sector also benefits from rutile titanium dioxide, as it aids in achieving desired colors and enhancing product transparency Titanium Dioxide Factory An In-Depth Look

Lithopone was discovered in the 1870s by DuPont. It was manufactured by Krebs Pigments and Chemical Company and other companies. The material came in different seals, which varied in the content of zinc sulfide. Gold seal and Bronze seals contain 40-50% zinc sulfide, offering more hiding power and strength. Although its popularity peaked around 1920, approximately 223,352 tons were produced in 1990. It is mainly used in paints, putty, and in plastics.

Are there any alternatives to toothpastes with titanium dioxide?

We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications

We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications We offer specialized TIO2 products that comply with strict regulatory standards, ensuring safety and efficacy in these sensitive applications tio2 products supplier.

tio2 products supplier. It turns into light gray after being exposed to ultraviolet rays in sunlight for 6 to 7 hours, but it will return to its original color when placed in a dark place. It is easy to oxidize in the air and then agglomerate and deteriorate when exposed to moisture.

Suppliers of titanium dioxide for coatings provide manufacturers with the raw material needed to produce high-quality coatings. These suppliers offer different grades and forms of titanium dioxide to meet the specific requirements of various coatings applications. Whether it is for architectural coatings, automotive coatings, or industrial coatings, suppliers of titanium dioxide play a critical role in ensuring that manufacturers have access to the right materials to produce coatings that meet their performance and aesthetic goals.While IARC listed titanium dioxide as “possibly carcinogenic to humans,” they also add that “there is inadequate evidence in humans for the carcinogenicity of titanium dioxide.” Of the four human studies that they reviewed, only one showed a potential risk for occupational workers inhaling titanium dioxide particles and lung cancer, while the other three showed no risk for cancer at all. And it’s key to note that IARC did not assess the effects of titanium dioxide found in foods.

The leading Chinese TiO2 exporter in value and quantity has been Sichuan Lomon, followed by Henan Billions and Gansu CNNC Huayuan. However, Sichuan Lomon exported a value of titanium dioxide by USD100,000,000 more than the second rank Henan Billions. Henan Billions, on the other hand, exported over USD70,000,000 more TiO2 than Gansu CNNC Huayuan. This demonstrates the huge monopole-like position of the newly merged company Henan Lomon, which can determine the market development for TiO2 in China nearly all alone.

In conclusion, China's titanium dioxide importers occupy a strategic position within the global market. Their actions reflect not only China's economic growth but also its evolving industrial needs and environmental consciousness. By fostering strong relationships with international producers and advocating for sustainable practices, these importers play an instrumental role in shaping the future of the titanium dioxide industry worldwide.CAS registration number: 1345-05-7

Solids were stable and did not show visible signs or changes in their spectra after being kept at room temperature for over 60 days. The absorbance at the maximum absorbance wavelength remained unmodified.

Overall, buff percentage is a critical factor that manufacturers of titanium dioxide must carefully manage to ensure the quality, consistency, and cost-effectiveness of their products. By investing in advanced technology and processes to control buff percentage, manufacturers can meet the specific requirements of their customers and maintain a competitive edge in the market. As the demand for titanium dioxide continues to grow across various industries, manufacturers must continue to innovate and improve their processes to meet the evolving needs of their customers.

In the vast landscape of chemical manufacturing, few names resonate with the same level of innovation and quality as Sachtleben. Known for their meticulous approach to production, Sachtleben has established itself as a leading titanium dioxide (TiO2) manufacturer under its TIO2 brand. Titanium dioxide, often recognized for its superior pigmenting properties, is widely used in industries ranging from paints and coatings to plastics and paper.