Links:

Aesthetic Differences Between Cast and Wrought Iron Fencing

In today's digital age, the internet is an invaluable resource. A simple Google search for wrought iron supply near me can yield a comprehensive list of suppliers within your vicinity. Be sure to read reviews and check ratings to ensure you're dealing with a reputable supplier. Many online stores offer detailed product descriptions, images, and even virtual consultations, making the purchasing process more convenient.

It is ideal for specific aluminum components prone to extreme wear environments and applications. You may also consider it in window and door applications, which require enhanced electrical insulation.

One of the standout features of these storage boxes is their secure locking mechanism. With a variety of lock options available, including combination locks, key locks, and padlocks, you can rest assured that your valuables are protected from unauthorized access. Many models also come with extra security features such as reinforced hinges and weatherproof seals, further enhancing their protective capabilities.Welding, an integral part of the manufacturing and engineering world, often brings to mind images of fiery sparks and molten metal. However, the process is not just about joining pieces together; it's a symphony of art and science, where even the most minute details, like metal leaves, play a crucial role. In this context, 'metal leaves for welding' refers to the technique of using thin, metallic sheets or 'leaves' as a part of the welding process, particularly in artistic and intricate welding applications.

Aluminum alloy louver frame profile

6. Lubricate the Rollers and Track Once you’ve successfully adjusted the rollers, apply a small amount of lubricant to the rollers and the track. This step is crucial as it reduces friction and ensures smoother operation over time.

To prolong the life of aluminum sliding door rollers and ensure optimal performance, regular maintenance is essential. Here are some best practices

Therefore, for internal use, it’s worth considering specialist internal window products with brands.

Applications and Market One of the primary advantages of a steel key box is its durability. Made from high-quality steel, these boxes are built to withstand the test of time and the elements. They are resistant to rust, corrosion, and damage from impact, making them an ideal choice for both indoor and outdoor use. Whether you live in a humid climate or a dry desert, a steel key box will keep your keys safe and secure. Antique collectors will find a treasure trove in our selection of vintage cast iron ornaments. Each piece, with its patina and history, tells a story waiting to be discovered. These relics from the past are not just decorations; they are snippets of history, preserved in iron.Ideally, aging during extrusion process ensures there is even precipitation of particles on the surface material.

2 cast iron panel casting. Melting Iron The next step is to melt the cast iron in a furnace. The iron is heated to a high temperature until it becomes molten.

cast iron panel casting. Melting Iron The next step is to melt the cast iron in a furnace. The iron is heated to a high temperature until it becomes molten. Wrought Iron & Ornamental Iron Differences

Security Features

Energy Efficiency

The process of welding metal leaves requires a high level of precision and skill. Due to their thinness, they can easily distort or burn through under intense heat, making the welding process a delicate balancing act between power and control. TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, with their ability to provide precise control over the heat source, are commonly employed for such tasks. The use of protective gases helps to prevent oxidation and maintain the integrity of the metal leaves during the process.

metal leaves for welding

The design and construction of door roller bearings are critical to their performance. Typically, these bearings consist of a steel or plastic wheel that rotates on a set of ball bearings enclosed within a housing. The housing is typically made of metal or plastic and is attached to the door frame. As the door moves along its track, the roller bearings allow it to glide smoothly and quietly, without any friction or resistance.

Exhibits Ideal Energy Efficiency

Furthermore, this type of lock box often comes equipped with high-security lock options, such as deadbolts or keypads, which offer an additional layer of protection

For those of us who want sheds that are very small, such as five square feet or less, then it will not really be necessary to add any sort of roof onto it. This is because you will only need to spend money on the framing itself and this is something that you can do yourself. Therefore, if you already have a strong foundation such as concrete then it will make sense to install a concrete wall as the main part of your shed.

Fire and Water Resistance

steel security safe lock box

1. Top-Mounted Rollers These rollers are attached to the top of the window sash. They are less visible and allow for a clean appearance. Top-mounted rollers are often used in heavy-duty applications where added support is needed.

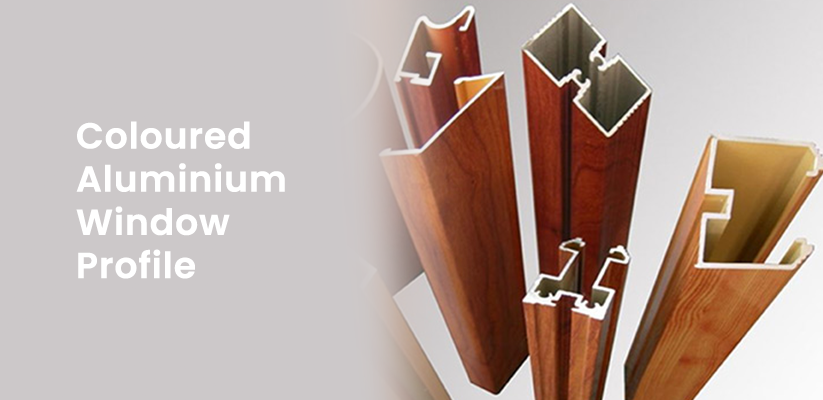

Application Of Aluminium Window Profile

The aesthetic appeal of screen door rollers should not be overlooked. Their sleek designs and minimalist profiles complement contemporary home architectures, adding value to properties by enhancing their visual appeal as well as their security. Moreover, sliding window roller wheels contribute significantly to energy efficiencyOverall, aluminum window extrusion profiles are a durable, versatile, and stylish option for windows in residential and commercial buildings. While they may have some drawbacks in terms of thermal performance, these can be mitigated with the right design and insulation choices. With proper care and maintenance, aluminum windows can provide homeowners with long-lasting beauty and functionality for years to come.

Conclusion

In contemporary fashion, designers play with the traditional concept of the decorative collar, integrating modern elements such as metallic threads, iridescent sequins, and bold patterns

decorative collars. This fusion of the classic and the contemporary results in pieces that can transform a plain dress into a party-ready ensemble or add a touch of whimsy to a corporate attire. The primary function of these lock boxes is key storage, particularly useful for real estate agents, property managers, or homeowners who need to grant access to their property without physically being present. A sturdy padlock or combination lock secures the contents within, preventing unauthorized access. Some models even feature a programmable digital lock for added convenience and security.

decorative collars. This fusion of the classic and the contemporary results in pieces that can transform a plain dress into a party-ready ensemble or add a touch of whimsy to a corporate attire. The primary function of these lock boxes is key storage, particularly useful for real estate agents, property managers, or homeowners who need to grant access to their property without physically being present. A sturdy padlock or combination lock secures the contents within, preventing unauthorized access. Some models even feature a programmable digital lock for added convenience and security.