Current location:

Links:

-

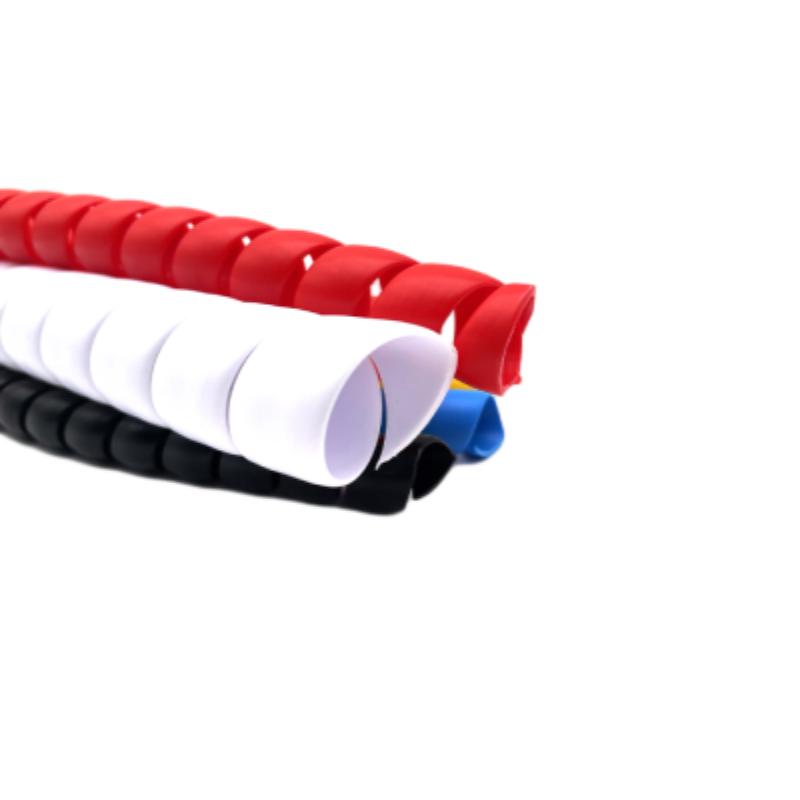

The 3 4 inlet hose connector refers to a pipe fitting designed to join two hoses or pipes with a diameter ratio of 34. This unique specification allows for the connection of a smaller hose or pipe to a larger one, facilitating the flow of liquids or gases between different sized conduits. The percentage notation indicates the size ratio, with '3' representing the smaller end and '4' the larger end of the connector. Properly dimensioned half couplings are crucial for the efficient operation of 3%, 204%, and NPT systems. By considering factors such as hub diameter, hub length, spring or bushing material, stiffness, and overall length, engineers can design or select a coupling that provides the necessary flexibility, strength, and durability for the intended application. Regular maintenance and inspection of half couplings are also essential to ensure their continued performance and longevity. At its core, 3% gas coupling refers to the optimal ratio of a specific gas, typically used as a carrier or moderator, to other reactants involved in a chemical process. This precise balance is crucial, as it can significantly influence reaction rates, selectivity, and overall efficiency. In some cases, it acts as a catalyst, enhancing the effectiveness of the primary reaction without being consumed in the process. When it comes to the world of luxury automobiles, Mercedes-Benz stands tall as a symbol of elegance, performance, and precision engineering. One critical component that significantly contributes to the smooth handling and driving experience of these vehicles is the Power Steering Hose. This article delves into the intricacies of this often-overlooked yet vital aspect of Mercedes' power steering system. Begin by safely elevating your Highlander using axle stands or a car lift. Once the vehicle is securely elevated, locate the power steering pump, typically found near the engine. The hose connects the pump to the steering rack or gearbox. Inspect the hose for cracks, swelling, or any signs of wear. In addition to regular maintenance, upgrading to a higher quality an line can provide improved durability and performance for power steering systems. Stainless steel braided lines, for example, offer increased strength and resistance to abrasion and corrosion, prolonging the lifespan of the power steering system. Metal hydraulic hose guards, also known as protective covers or shields, are designed with a primary objective to shield the hose from external damage, such as sharp edges, abrasions, and impacts. These guards are typically made of robust materials like stainless steel or aluminum, ensuring durability and resistance to corrosion. Their construction is critical, as they must maintain flexibility while providing adequate protection. Moreover, Camlock hoses come in a range of diameters and lengths, allowing users to customize their setup to fit specific needs To replace the power steering hose in a 1998 Silverado, you'll need to first locate the old hose. The power steering hoses are typically located near the power steering pump and the steering rack. Once you've located the hose, you'll need to disconnect it from the power steering pump and the steering rack. This can be done using a wrench or a pair of pliers to loosen the hose clamps. Final Steps and Checks * Stiff or binding steering If you feel resistance when you turn the steering wheel, it could be due to a restricted hose or a buildup of debris inside the system

power steering hose for 2006 honda odyssey.

power steering hose for 2006 honda odyssey.

Compatibility and Sizing: Ensure that the air conditioning hoses are compatible with the bus's air conditioning system and that they have the correct sizing and specifications. Using the wrong size or type of hose can lead to performance issues and refrigerant leaks.

Furthermore, the union coupling is not just limited to plumbing applications. It finds its usage in diverse industries, including automotive, chemical processing, and even in the aerospace sector for fluid management systems. Its ability to withstand pressure and temperature variations makes it a reliable choice across multiple domains. In case of a leak, it's not always necessary to replace the entire hose. Often, a repair kit with replacement fittings and clamps can fix the issue. However, if the hose has suffered significant damage or is old, a complete replacement is recommended. In conclusion, the pressure hose is a critical link in the chain of the power steering pump system, working silently behind the scenes to provide the necessary assistance for comfortable and safe driving. Its reliability is a testament to the engineering ingenuity that goes into designing an efficient and user-friendly automotive experience. Regular maintenance and understanding its importance can significantly contribute to the overall health and longevity of our vehicles. A power steering hose leak can be a significant inconvenience for any car owner, leading to reduced steering efficiency and potential damage to your vehicle's engine. Here's a step-by-step guide on how to diagnose, troubleshoot, and stop a power steering hose leak. 4. **Check Pressure** Use the digital gauge to check the initial pressure readings. Once both ends of the hose are connected, bleed the system to remove any air bubbles that may have been trapped during the installation process. To do this, start the engine and turn the steering wheel from lock to lock several times, while simultaneously pumping the brake pedal. You should see a steady stream of fluid coming out of the power steering reservoir. In large-scale applications like industrial facilities, municipal water systems, or agricultural irrigation, these connectors are crucial The durability and quality of the power steering hose are critical. Made from high-quality materials like synthetic rubber or braided steel, these hoses can withstand extreme temperatures and high pressure. However, over time, wear and tear, leaks, or damage can occur, impacting the steering performance. If the hose fails, it can lead to loss of power steering assistance, making the car difficult to steer, and potentially causing safety issues. In the intricate world of modern machinery, the 3/4 power steering hose is a vital component that often goes unnoticed. This humble part plays a crucial role in ensuring the smooth operation of many vehicles, from heavy-duty trucks to compact cars. At 20 inches in length, this particular power steering hose is designed to provide an optimal balance between performance and space efficiency. Replacing the power steering hose on a Jeep XJ is a relatively straightforward process that can be done at home with the right tools and a little bit of know-how. To begin, you will need to gather the necessary tools and materials, including a new power steering hose, a wrench set, a socket set, power steering fluid, and a drain pan. You will also need to lift the front of the vehicle using a jack and jack stands to access the power steering components easily. Regular maintenance of the power steering hose is essential for Corvettes In installation, these connectors require precise measurement and alignment to ensure optimal performance

The durability and quality of the power steering hose are critical. Made from high-quality materials like synthetic rubber or braided steel, these hoses can withstand extreme temperatures and high pressure. However, over time, wear and tear, leaks, or damage can occur, impacting the steering performance. If the hose fails, it can lead to loss of power steering assistance, making the car difficult to steer, and potentially causing safety issues. In the intricate world of modern machinery, the 3/4 power steering hose is a vital component that often goes unnoticed. This humble part plays a crucial role in ensuring the smooth operation of many vehicles, from heavy-duty trucks to compact cars. At 20 inches in length, this particular power steering hose is designed to provide an optimal balance between performance and space efficiency. Replacing the power steering hose on a Jeep XJ is a relatively straightforward process that can be done at home with the right tools and a little bit of know-how. To begin, you will need to gather the necessary tools and materials, including a new power steering hose, a wrench set, a socket set, power steering fluid, and a drain pan. You will also need to lift the front of the vehicle using a jack and jack stands to access the power steering components easily. Regular maintenance of the power steering hose is essential for Corvettes In installation, these connectors require precise measurement and alignment to ensure optimal performance 3 4 inch water pipe connector. Professional plumbers often use specialized tools to tighten and align them, ensuring airtight connections. Regular maintenance and inspection are also vital to prevent any potential issues like rusting, loosening, or wear and tear. The Land Cruiser 100 Power Steering Hose A Key Component for Optimal Driving Experience 2. Poor Installation If the power steering hose was not installed correctly during manufacturing or maintenance, it may develop leaks at the joints or fittings. . 2. Poor Installation If the power steering hose was not installed correctly during manufacturing or maintenance, it may develop leaks at the joints or fittings.

3 4 inch water pipe connector. Professional plumbers often use specialized tools to tighten and align them, ensuring airtight connections. Regular maintenance and inspection are also vital to prevent any potential issues like rusting, loosening, or wear and tear. The Land Cruiser 100 Power Steering Hose A Key Component for Optimal Driving Experience 2. Poor Installation If the power steering hose was not installed correctly during manufacturing or maintenance, it may develop leaks at the joints or fittings. . 2. Poor Installation If the power steering hose was not installed correctly during manufacturing or maintenance, it may develop leaks at the joints or fittings. If any issues are identified, it is recommended to replace the high-pressure power steering hose as soon as possible to ensure the continued performance and safety of the vehicle. It is also advisable to use high-quality replacement parts that meet or exceed the specifications of the original equipment manufacturer. Threaded couplings feature screw threads on both ends, enabling them to be securely fastened to the pipes. These threads can either be male (external) or female (internal), depending on the type of connection required. When two threaded couplings are twisted together, they form a tight seal, preventing any leakage and ensuring the smooth transfer of fluids. Maintenance Requirements The power steering hose is usually made of rubber or high-pressure hydraulic hose material, which is designed to withstand the high pressures and temperatures that are present in the power steering system. The construction of the power steering hose is crucial to ensure that it can withstand the constant movement and vibration of the vehicle's steering system without leaking or failing. Nissan Xterra Power Steering Hose A Comprehensive Overview When a technician arrives to repair your air conditioner line, they will first inspect the line for any visible damage or blockages. They may use special tools such as a pressure gauge or a refrigerant leak detector to pinpoint the exact location of the problem. Once the issue has been identified, the technician will repair or replace the damaged section of the line to restore proper airflow and refrigerant circulation. 3. **Draining Fluid** Disconnect the negative battery terminal for safety. Then, drain the power steering fluid by removing the reservoir cap and placing a container underneath to catch the fluid. The Vital Role of Brake Fluid Lines in Automotive Safety A power steering hose plays a pivotal role in Nissan's advanced steering system. It is essentially a high-pressure hose that transfers hydraulic fluid from the power steering pump to the steering gear or rack, assisting drivers in maneuvering the vehicle with ease. The fluid under pressure helps to reduce the effort needed to turn the steering wheel, especially at low speeds or when parking. A pipe coupling is a mechanical device used to join two pipes or tubes, allowing the flow of liquids or gases to continue uninterrupted. They come in different shapes and sizes, designed to cater to the diverse requirements of plumbing systems. However, it's the threaded pipe coupling that steals the spotlight due to its unique design and functionality. Power steering, an essential component in modern vehicles, significantly enhances driving comfort and maneuverability by reducing the effort required to turn the steering wheel. A critical element within this system is the pressure hose, which plays a pivotal role in the power steering mechanism. Over time, however, even the most durable power steering hoses can become worn or damaged, leading to leaks and loss of power steering fluid. If not addressed promptly, these issues can cause significant damage to the steering system and even render the vehicle inoperable. One of the key advantages of a pressurized sewer jetter lies in its versatility. It can be employed for various applications, from residential drain cleaning to extensive commercial and industrial pipeline maintenance. Its compact design allows it to navigate tight spaces and long distances, making it suitable for both small-scale domestic issues and large-scale municipal projects. Moreover, custom brake lines are less prone to failure

custom brake lines for cars. Over time, factory rubber hoses can deteriorate, crack, or bulge, potentially leading to brake fluid leaks and compromised braking efficiency. With custom brake lines, such issues are significantly reduced, ensuring a safer and more reliable braking system. A Comprehensive Guide to Replacing the Power Steering Hose on an Audi A4 An Essential Maintenance Task Proper maintenance of the power steering hose is essential to ensure the longevity and performance of the steering system 5. **Install the New Hose** Slide the new hose onto the steering rack, ensuring proper alignment with the fittings. Apply new grease to the O-rings for a secure seal.

custom brake lines for cars. Over time, factory rubber hoses can deteriorate, crack, or bulge, potentially leading to brake fluid leaks and compromised braking efficiency. With custom brake lines, such issues are significantly reduced, ensuring a safer and more reliable braking system. A Comprehensive Guide to Replacing the Power Steering Hose on an Audi A4 An Essential Maintenance Task Proper maintenance of the power steering hose is essential to ensure the longevity and performance of the steering system 5. **Install the New Hose** Slide the new hose onto the steering rack, ensuring proper alignment with the fittings. Apply new grease to the O-rings for a secure seal. The standard barrier ac hose refers to the thick wall ac hose. It means the outer layer of ac hose is very thick. It aims to have a good permeation resistance and burst strength.

2. **Solvent Couplers** Solvent couplers are designed for use in corrosive environments and are resistant to solvents, acids, and other chemicals. They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions

They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions They are commonly used in chemical processing plants and other industries that require resistance to harsh conditions upvc coupler price.

upvc coupler price.