3. Automotive Repairs Car enthusiasts have also found this tape useful for temporary fixes, such as covering a damaged hose or sealing a leaking coolant reservoir, allowing for safe driving until proper repairs can be made.

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion. In conclusion, cloth tape for electrical is a versatile and indispensable tool for insulating, organizing, and protecting electrical connections and components. Its durability, flexibility, and ease of use make it the perfect choice for a wide range of electrical applications. Whether you are a professional electrician or a DIY enthusiast, cloth tape for electrical is a must-have item for your toolkit.

fire seal tape. It can be applied around electrical outlets, piping, and HVAC ducts to prevent the spread of fire through these vulnerable areas. It can also be used to seal gaps around doors and windows, helping to create a barrier against fire and smoke intrusion. In conclusion, cloth tape for electrical is a versatile and indispensable tool for insulating, organizing, and protecting electrical connections and components. Its durability, flexibility, and ease of use make it the perfect choice for a wide range of electrical applications. Whether you are a professional electrician or a DIY enthusiast, cloth tape for electrical is a must-have item for your toolkit. Supply Voltage and Motor Amperage

Automotive electrical tape fabric, often referred to as auto electrical tape or automotive tape, is a crucial component in the automotive industry. It is used for a wide range of purposes, including insulating, protecting, and securing wires, cables, and other electrical components in vehicles. In this comprehensive guide, we will delve into the various aspects of automotive electrical tape fabric, including its properties, types, applications, and benefits. Moreover, butyl foil tape finds application in the solar industry as well. Its UV resistance and excellent adhesion properties ensure it can withstand the harsh outdoor conditions, making it perfect for sealing solar panels and preventing water ingress. Automotive wiring loom wrap is an essential component in the construction and maintenance of vehicles. It is used to protect and organize the numerous wires that run throughout a car, ensuring that they are secure and safe from damage.For best results, clear any debris or dirt away from the surface to which you’re applying the tape

Another important feature of rubber electrical tape is its high dielectric strength. This means that the tape is able to withstand high voltages without breaking down or conducting electricity. This is crucial for maintaining the integrity of the insulation and preventing electrical accidents. PVC Tape Insulation A Versatile and Cost-Effective Solution Waterproof butyl rubber tape is characterized by its unique composition, which consists of butyl rubber, tackifier resins, and various additives. The butyl rubber base provides excellent impermeability to gases and liquids, making it ideal for sealing joints and seams in various applications. The tackifier resins enhance the adhesion of the tape to different surfaces, ensuring a secure bond. Additionally, the additives improve the flexibility, weather resistance, and aging characteristics of the tape.1. Prepare the surface Before applying the tape, make sure the surface is clean and dry. Remove any dirt, grease, or debris from the surface to ensure a proper seal.

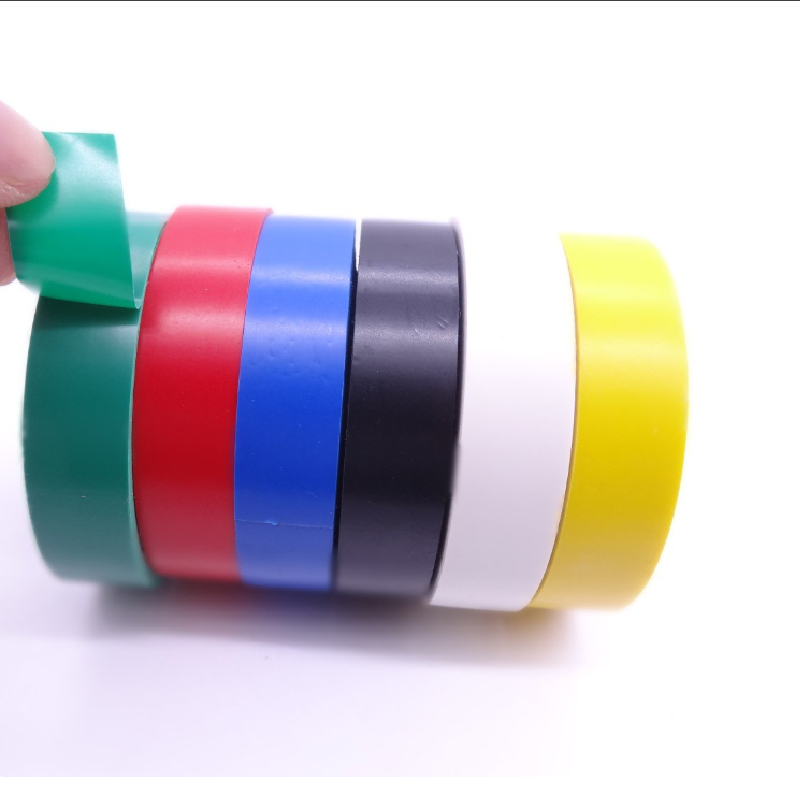

> Moreover, high tension insulation tape comes in a variety of colors, each with specific industry standards Another important property of butyl rubber adhesive tape is its excellent resistance to UV radiation, ozone, and temperature fluctuations. This makes it a reliable choice for outdoor applications, where it can be exposed to sunlight and harsh weather conditions without deteriorating or losing its adhesive properties

butyl rubber adhesive tape. The tape is also resistant to chemicals, which makes it suitable for use in industrial environments where it may come into contact with oils, solvents, and other chemicals. In addition to its sealing and insulating properties, butyl rubber tape is also highly durable and long-lasting

Moreover, the ease of application is another feather in the cap of PVC tape insulation

Moreover, the ease of application is another feather in the cap of PVC tape insulation tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.

tape insulation pvc. It can be easily wrapped around wires and cables, requiring minimal tools and expertise. Its self-adhesive property ensures a firm grip, eliminating the need for additional sealing or binding materials.

In addition to their practical benefits, waterproof door seal strips also add an aesthetic touch to any home. Many models come in a range of colors and designs to match different interior decor styles, making them an attractive and functional addition to any home. While heat tape electric is an effective solution for preventing frozen pipes, it is important to remember that it is not a permanent fix. It is recommended to insulate exposed pipes and take other preventative measures to ensure your pipes are protected during the winter months.

In addition to their practical benefits, waterproof door seal strips also add an aesthetic touch to any home. Many models come in a range of colors and designs to match different interior decor styles, making them an attractive and functional addition to any home. While heat tape electric is an effective solution for preventing frozen pipes, it is important to remember that it is not a permanent fix. It is recommended to insulate exposed pipes and take other preventative measures to ensure your pipes are protected during the winter months.