Links:

- Easy Application and Removal: Polyethylene Rubber Tape is generally easy to apply and remove. It can be torn by hand or cut to the desired length, and the adhesive allows for secure bonding while still enabling clean removal when needed.

- Pipe Wrapping and Corrosion Protection Pink flagging tape is a common sight on construction sites and outdoor areas where work is being done. This brightly colored tape is used to mark boundaries, indicate hazards, and provide guidance to workers. While it may seem like a simple tool, the uses and importance of pink flagging tape should not be underestimated. Flame proof tape is typically made from materials that have high resistance to heat and flames. These materials include fiberglass, aluminum foil, and special resins. When applied correctly, these tapes create a barrier that prevents the passage of flames, sparks, and hot gases. This is particularly useful in situations where flammable substances are present or where there is a risk of fire due to electrical faults or other causes.

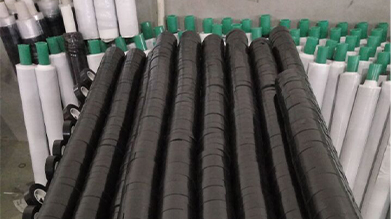

- Polyethylene Tape is used for wrapping and protecting pipes to prevent corrosion and provide insulation. It forms a barrier against moisture, chemicals, and other corrosive substances, making it ideal for applications in plumbing, oil and gas industries, or underground pipelines.

floor tape. From creating geometric patterns on gallery floors to defining zones in pop-up events, its transformative power is being celebrated. The tape's removable nature allows for temporary installations, making it a favorite among artists and event planners seeking a low-cost, high-impact solution.

floor tape. From creating geometric patterns on gallery floors to defining zones in pop-up events, its transformative power is being celebrated. The tape's removable nature allows for temporary installations, making it a favorite among artists and event planners seeking a low-cost, high-impact solution. Polyethylene film tape (6350X) is a 5.5-mil thick tape with acrylic rubber adhesive. This film tape is flexible, conformable, durable, and chemical resistant. It is also resistant to tears, punctures, and abrasions, which makes it a good protective tape. It is also a good barrier tape for gas and moisture-proofing. Taping with polyethylene film tape produces a permanent bond with no edge bleeding.

Using self-amalgamating tape for leaks is simple and straightforward. To apply the tape, all you need to do is clean and dry the surface, stretch the tape to the desired length, and wrap it around the affected area. As you wrap the tape, it will bond to itself and create a tight seal that will prevent any further leakage. You can then trim any excess tape and smooth out any wrinkles to ensure a neat and professional-looking repair. 1. Improved Safety By providing effective insulation and preventing short circuits, automotive wire wrap tape helps ensure the safety of drivers and passengers.Hot Melt

4. Household Uses Beyond repairs, Black Flex Tape can also be used for various household projects. From reinforcing furniture to crafting and creating custom solutions, its strength and versatility make it a handy tool for everyday tasks.

Overall, Flex Tape Black 4 in x 5 ft is a versatile and reliable solution for all your waterproofing needs. Whether you are a DIY enthusiast tackling a home improvement project or a professional contractor looking for a reliable sealant, Flex Tape Black is sure to meet your needs. With its flexibility, strength, and ease of use, Flex Tape Black is the perfect choice for all your sealing and repairing needs.

Quantity: 1 roll pack

The durability of rubber Flexx tape is further enhanced by its weather-resistant qualities. It remains effective in extreme temperatures, from the freezing cold to the blistering heat, ensuring year-round protection against leaks and wear. There are several compelling reasons why engineers and contractors prefer to use semi-conductive water blocking tape Additionally, the strong adhesive properties of this tape ensure a secure bond that will hold up under even the most demanding conditions

130c linerless rubber splicing tape. Whether used for electrical insulation, sealing, or bonding, the 130c% linerless rubber splicing tape provides a reliable and long-lasting solution.

Butyl rubber waterproofing is also highly versatile and can be used in a variety of applications. In construction projects, it is commonly used to seal joints, seams, and penetrations in buildings, ensuring that water cannot seep through and cause damage. In industrial settings, butyl rubber waterproofing can be applied to storage tanks, pipelines, and other structures to prevent corrosion and deterioration. In residential buildings, butyl rubber waterproofing can be used to protect basements, roofs, and balconies from water infiltration, extending the lifespan of the building and reducing maintenance costs.

As described in the article “How Polyimide Tapes are Made“, tapes are composed of two distinct layers, each of which is critical to the properties of the final product. The first layer is the backing material, and whether this is polyimide film (the generic verison of DuPont’s Kapton), polyvinyl chloride (PVC), Polyethylene terephthalate (PET), or some other plastic, cloth or paper material, this layer is selected to provide half of the tape’s final properties. The other half is determined by the adhesive layer applied to this backing layer.

One key advantage of black butyl rubber sealant is its ability to adhere effectively to a wide range of surfaces, including metal, glass, plastic, and concrete. This broad compatibility ensures that it can be used in diverse applications, from sealing joints in roofing systems to securing window and door installations. Its excellent waterproofing capabilities prevent water infiltration, thereby increasing the lifespan of structures and components. 2. Retractable Tape This tape features a spring-loaded mechanism that allows it to be easily extended and retracted as needed. It is particularly useful for temporary hazards or when frequent repositioning is required. The primary function of self-adhesive PVC insulation tape is to insulate and protect electrical wires and cables. It safeguards conductors from damage, prevents short circuits, and ensures that electrical currents flow safely along their designated paths. Its conformability allows it to adhere seamlessly to irregular surfaces, making it ideal for wrapping around curved or contoured wire bundles.Acrylic adhesives are generally divided into two subgroups: Pure and Modified

(5) For occasions requiring complete flame retardant, flame retardant products are also available;

4. Thermal management The tape can be used to dissipate heat from electronic components, preventing overheating and potential failure. In conclusion, yellow and black tape for floor markings plays a crucial role in enhancing safety, organization, and efficiency in a wide range of settings. Its high visibility, ease of use, and versatility make it an indispensable tool for maintaining order and preventing accidents. Whether in construction sites, warehouses, factories, or public spaces, this simple yet effective tool continues to prove its value in creating a safer and more structured environment for everyone.Another benefit of using 3M amalgamating tape is its ease of use. Unlike traditional tapes that require scissors or other tools for cutting, this tape can be torn by hand, making it quick and convenient to apply in tight spaces or emergency situations.

The interface is the display component that gives you access to your control box. It allows you to set your control box or even perform diagnostics. Typical control box interfaces come in the form of switches and boxes. However, there are advanced interfaces that include touchscreens.

In summary, heat tape is a versatile and invaluable tool across multiple sectors. Its ability to provide precise, reliable heat makes it essential for preventing frost damage in pipes, crops, and buildings. As field technology advances, the efficiency and performance of heat tape continue to improve, cementing its role as a go-to solution for temperature management. Whether used in residential settings or industrial applications, understanding how to properly use and install heat tape can lead to significant benefits and peace of mind during cold weather conditions. With proper care and consideration, heat tape remains an investment in safety and efficiency.

In conclusion, cloth insulation tape is more than just a simple adhesive strip; it's a multi-faceted tool that plays a vital role in ensuring safety, efficiency, and functionality in various industries. Its versatility, durability, and insulating properties make it an indispensable asset in our modern world, highlighting the importance of understanding and utilizing it correctly. Whether it's securing wires, supporting athletes, or fixing leaks, cloth insulation tape continues to prove its worth time and again. In conclusion, red and white floor tape is a valuable resource for businesses and organizations looking to maintain a safe and organized workspace. By understanding the uses and benefits of this tape, employers can make informed decisions about how to implement it in their facility. Whether marking off hazardous areas, organizing traffic flow, or providing guidance to employees and visitors, red and white floor tape is a simple yet effective tool that can help improve safety and efficiency in any workplace.

2. Stretch the tape Most amalgamating tapes come on a roll and need to be stretched before application. Gently stretch the tape to activate the adhesive properties.

Incorporating door seals with rubber strips into your home maintenance routine is a small change with big rewards. It's an affordable and efficient way to upgrade your living space, offering benefits that range from cost savings to improved comfort. By sealing those unseen gaps, you not only enhance the energy efficiency of your home but also create a more tranquil and comfortable living environment. It’s an investment that pays off in comfort, savings, and the peace of mind that comes from knowing your home is well-protected against the elements. In the electrical industry, insulation cotton tape is an essential component in the production and maintenance of electrical equipment. It is used to insulate wires, cables, and joints to prevent short circuits, electrocution, and fire hazards. The tape is also used to repair damaged insulation on electrical components, ensuring their proper functioning.