Links:

High pressure hydraulic shaft seals can be categorized into several types, including

In the world of mechanical engineering, high-pressure rotary shaft seals play a vital role in maintaining the integrity and efficiency of machinery. These seals are designed to prevent the leakage of fluids and contaminants from the rotating shaft of a machine, which is crucial for the overall performance and longevity of various automotive, industrial, and aerospace applications. This article explores the significance, functioning, and advancements in high-pressure rotary shaft seals.

In conclusion, agricultural seals are a powerful tool for promoting food security and sustainability in the agricultural industry. By ensuring the quality, safety, and environmental friendliness of agricultural products, these seals help to build consumer trust and drive the adoption of sustainable practices. As the demand for sustainable food continues to grow, the role of agricultural seals will only become more important. Another important consideration when choosing a hydraulic oil seal is its installation method

Seals, in particular, are critical elements that need regular attention. They prevent fluid leakage and maintain system pressure They prevent fluid leakage and maintain system pressure

Seals, in particular, are critical elements that need regular attention. They prevent fluid leakage and maintain system pressure They prevent fluid leakage and maintain system pressure They prevent fluid leakage and maintain system pressure They prevent fluid leakage and maintain system pressure

They prevent fluid leakage and maintain system pressure They prevent fluid leakage and maintain system pressure hydraulic cylinder kits repair. If seals are worn or damaged, it can lead to loss of efficiency and increased downtime. Choosing the right seal kit for your specific cylinder model is crucial, as different seals have varying tolerances and compatibility with different fluids.

hydraulic cylinder kits repair. If seals are worn or damaged, it can lead to loss of efficiency and increased downtime. Choosing the right seal kit for your specific cylinder model is crucial, as different seals have varying tolerances and compatibility with different fluids. 3. V-Ring Seals V-ring seals are flexible and can handle both radial and axial movement, making them versatile for various applications. They are particularly useful in dynamic sealing situations where shaft movement is significant.

Understanding Hydraulic Motor Oil Seals Importance and Applications

When it comes to hydraulic seal replacement, there are a few important steps that need to be taken. First and foremost, it is essential to identify the type of hydraulic seal that needs to be replaced. There are different types of seals, including rod seals, piston seals, wiper seals, and O-rings, each serving a specific purpose within the hydraulic system. The environmental benefits are equally compelling

hydraulic ram kit. Unlike traditional pumping systems powered by fossil fuels or electricity generated from non-renewable sources, the hydraulic ram kit leaves a minimal carbon footprint. It operates solely on the natural flow of water, meaning it contributes little to pollution or greenhouse gas emissions.

hydraulic ram kit. Unlike traditional pumping systems powered by fossil fuels or electricity generated from non-renewable sources, the hydraulic ram kit leaves a minimal carbon footprint. It operates solely on the natural flow of water, meaning it contributes little to pollution or greenhouse gas emissions. When selecting a hydraulic cylinder seal kit by size, it's essential to accurately measure the dimensions of your cylinder to ensure compatibility. Most seal kits come with detailed instructions on how to measure your cylinder properly and select the right kit size. It's crucial to choose a reputable manufacturer or supplier to guarantee the quality and durability of the seals.

hydraulic cylinder seal kits by size

In the realm of mechanical engineering and industrial applications, ensuring the integrity and efficiency of rotating equipment under varying pressure conditions is critical. High pressure rotary seals play an essential role in this context, providing crucial solutions for preventing leaks and ensuring the smooth operation of machinery.

2. Contamination Control Besides maintaining pressure, seals also protect the internal components from dirt, dust, and other contaminants that can enter the cylinder. A robust sealing system ensures that these foreign particles do not compromise the cylinder's functionality, which can drastically affect the overall performance and lifespan of the hydraulic system.

In addition to containing the fluid, hydraulic shaft seals also help to protect the system from contamination. Dust, dirt, and other particles can enter the system through a damaged seal, causing abrasive wear on the components and reducing the efficiency of the system. By creating a tight seal around the shaft, hydraulic seals help to maintain the cleanliness and integrity of the hydraulic system. The primary seal, often made of polyurethane, rubber, or PTFE (Teflon), prevents fluid from leaking past the piston. The secondary seal, typically an O-ring, provides additional security against fluid bypass. Wear rings, usually made of hard materials like bronze or steel, reduce friction and prevent scoring of the cylinder wall. Scraper seals help remove any contamination or debris that may have entered the system Scraper seals help remove any contamination or debris that may have entered the system

Scraper seals help remove any contamination or debris that may have entered the system Scraper seals help remove any contamination or debris that may have entered the system

Scraper seals help remove any contamination or debris that may have entered the system Scraper seals help remove any contamination or debris that may have entered the system hydraulic piston seal kit. Single lip oil seals are commonly used in a wide range of machinery and automotive applications Moreover, regular maintenance and timely replacement of oil seals like the 30x42x7 are vital to prevent costly downtime and potential machine failures. Inspections should be conducted regularly to check for signs of wear, damage, or leakage, and seals should be replaced as needed to maintain the overall health of the system.

hydraulic piston seal kit. Single lip oil seals are commonly used in a wide range of machinery and automotive applications Moreover, regular maintenance and timely replacement of oil seals like the 30x42x7 are vital to prevent costly downtime and potential machine failures. Inspections should be conducted regularly to check for signs of wear, damage, or leakage, and seals should be replaced as needed to maintain the overall health of the system. What are High Pressure Rotary Seals?

One of the key factors to consider when choosing oil seals is the material used in their construction. Oil seals are typically made from materials such as nitrile rubber, silicone rubber, and polyacrylate. Each material has its own set of advantages and disadvantages, and it is important to select a material that is suited to the specific application and operating conditions. Now, the ' ' part is particularly intriguing To ensure uninterrupted operation and to extend the lifespan of a 3-inch hydraulic cylinder, regular inspection and replacement of the seal kit is imperative. This proactive approach helps to identify any signs of wear or damage before they escalate into more severe issues. Additionally, adhering to the manufacturer's guidelines regarding the use of genuine parts and lubricants further enhances the reliability of the seal kit. One of the key benefits of a dust proof seal is its ability to prevent the ingress of foreign particles into a device or system. Dust and dirt can cause friction and wear on moving parts, leading to increased maintenance and repair costs. By sealing off the internal components from external contaminants, a dust proof seal helps to extend the lifespan of the product and maintain its optimal performance.

4. Customer Support and Service Reliable manufacturers offer excellent customer support, from initial inquiries to after-sales service. They should be responsive and willing to provide guidance on the best seal for your requirements.

Moreover, the design of this oil seal incorporates features that enhance its performance The dkb seal is also known for its intelligence and cunning. It is always one step ahead of its prey, able to anticipate their every move and outmaneuver them with ease. Its sharp reflexes and quick thinking make it a formidable hunter, able to catch fish and other prey with ease

dkb seal. In conclusion, the hydraulic ram kit stands as a symbol of self-sufficiency and environmental sustainability. Its operation, rooted in the principles of physics, demonstrates how the force of water can be harnessed for practical applications. With continued advancements in design and materials, hydraulic ram kits are likely to remain a reliable option for water supply in areas where conventional methods fall short. 5. Reassemble the cylinder After the new seals are installed, the cylinder can be reassembled by putting the internal components back in place and reattaching the end caps. Care must be taken to tighten the bolts properly to prevent any leaks or damage.

Signs of Worn Seals

2. Contamination Prevention These seals also prevent the ingress of contaminants such as dirt, dust, and moisture, which could otherwise compromise the functionality of the machinery.

When selecting hydraulic cylinder seals, it is essential to consider factors such as temperature, pressure, and the type of fluid being used. Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application

Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application

Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application Different materials and designs are better suited to different operating conditions, so it is crucial to choose the right seal for the specific application hydraulic cylinder seals for sale. For example, elastomer seals are well-suited for low to moderate pressures and temperatures, while metal seals can withstand higher pressures and temperatures. A hydraulic floor jack repair kit typically includes replacement parts such as seals, O-rings, valves, and hydraulic fluid. These parts are essential for repairing common issues such as leaks, malfunctions, and low hydraulic pressure. In the broader context of industrial applications, motor seal kits represent a fundamental piece of the machinery puzzle. They allow for the creation of robust systems capable of withstanding the rigors of industrial environments while maintaining optimal performance levels. As industries continue to push for greater efficiency and sustainability, the humble motor seal kit stands as a testament to the idea that even the smallest components can have a significant impact on success.

hydraulic cylinder seals for sale. For example, elastomer seals are well-suited for low to moderate pressures and temperatures, while metal seals can withstand higher pressures and temperatures. A hydraulic floor jack repair kit typically includes replacement parts such as seals, O-rings, valves, and hydraulic fluid. These parts are essential for repairing common issues such as leaks, malfunctions, and low hydraulic pressure. In the broader context of industrial applications, motor seal kits represent a fundamental piece of the machinery puzzle. They allow for the creation of robust systems capable of withstanding the rigors of industrial environments while maintaining optimal performance levels. As industries continue to push for greater efficiency and sustainability, the humble motor seal kit stands as a testament to the idea that even the smallest components can have a significant impact on success. - Application Requirements Different applications may require specific types of seals based on temperature, pressure, and fluid type. Understanding the application’s demands will guide the selection process.

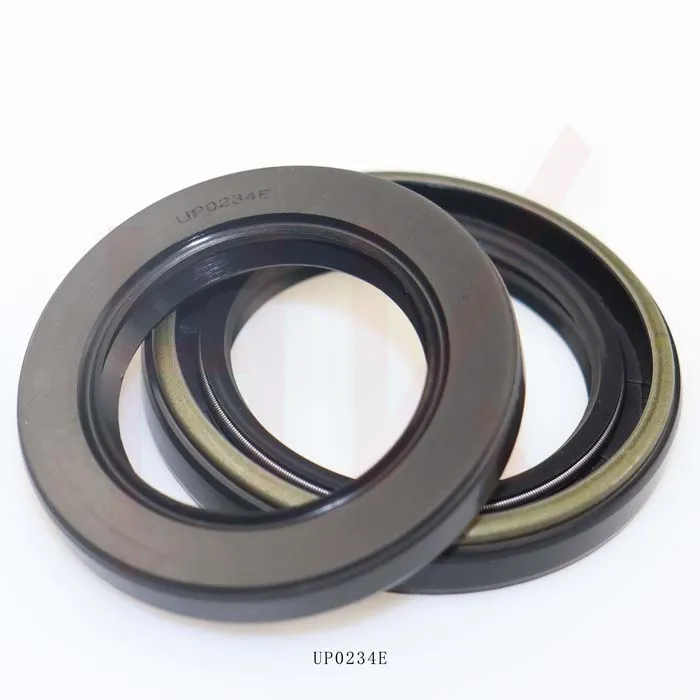

Oil seals play a crucial role in various machinery and industrial equipment by preventing the leakage of oil and other fluids. These seals are essential components of engines, pumps, and other rotating or reciprocating machinery, helping to maintain proper lubrication and prevent contamination. In this article, we will delve into the importance of oil seals and the different factors to consider when choosing the right oil seal for your application.

When selecting a double lip oil seal, it is important to consider factors such as the shaft diameter, operating temperature, pressure, and speed. Proper installation and maintenance are also crucial to ensure optimal performance and longevity of the seal. There are various types of dust proof seals available, each designed to meet specific requirements and preferences. Some seals are made from rubber or silicone, offering flexibility and durability for a wide range of applications. Others are designed with specialized materials and coatings to enhance their resistance to harsh environments and chemicals.

There is a wide variety of hydraulic piston oil seals, designed to meet specific operational demands. Some common types include

hydraulic piston oil seals

Another advantage of double lip oil seals is their versatility

double lip oil seal. They can be used in a wide range of applications, from automotive engines and transmissions to industrial machinery and hydraulic systems. Their flexibility and reliability make them a popular choice for many different industries.

double lip oil seal. They can be used in a wide range of applications, from automotive engines and transmissions to industrial machinery and hydraulic systems. Their flexibility and reliability make them a popular choice for many different industries. Conclusion

Furthermore, our commitment to innovation means that we are always at the forefront of developing new and improved oil seal designs The importance of rubber hub seals extends beyond their ability to protect the brake system. They also play a crucial role in maintaining the overall integrity of the wheel assembly. Over time, the wheel bearings and other components within the hub can become worn or damaged. A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants

A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants

A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants A well-designed rubber hub seal can help to prevent these issues by creating a sealed environment that keeps out harmful contaminants rubber hub seal.

rubber hub seal. Tools and Materials Needed

Several factors can influence the performance and durability of hydraulic ram oil seals

Dimensions and Specifications

Material and Durability

Installation of the 20x30x7 oil seal requires precision and care. It must be correctly aligned with the shaft to prevent any damage during fitting, and the mating surfaces should be clean and free from burrs to ensure an effective seal. Regular maintenance and inspection are essential to ensure the continued integrity of the seal, as worn or damaged seals can lead to oil leaks, equipment failure, and increased maintenance costs. The Importance of Pump Seal Oil in Industrial Applications In the world of mechanical engineering, the quest for efficient and reliable sealing solutions is paramount. This pursuit has led to the development of innovative products like the cross cylinder seal kit, a revolutionary solution that promises to address the challenges associated with traditional sealing methods. In this article, we will explore the features, benefits, and applications of the cross cylinder seal kit. One common type of hydraulic oil seal is the single-lip seal. This type of seal features a single lip that contacts the shaft to prevent the leakage of hydraulic fluid. Single-lip seals are often used in applications where space is limited, as they have a smaller overall profile compared to other seal types. They are also relatively easy to install and replace, making them a popular choice for many hydraulic systems. Ensuring Optimal Performance The Significance of Forklift Hydraulic Cylinder Seals