Links:

2. Feeding System The feeding system guides the bags into the machine at a consistent speed. This component typically includes a conveyor belt or rollers that facilitate smooth movement. An efficient feeding system minimizes the risk of jams and ensures a continuous workflow, which is essential for high-volume production environments.

1. Stitch Variety Professional upholstery sewing machines typically offer an array of stitches, including straight, zigzag, and specialty stitches. This variety enables upholsterers to create tailored designs and finishes, elevating the aesthetic appeal of their work.

In conclusion, the industrial lockstitch machine is an essential tool for businesses looking to create high-quality products efficiently and effectively. With its precise stitching, high-speed performance, versatility, and durability, this machine offers a range of benefits that can help businesses streamline their production processes and deliver superior products to their customers. Whether you are a small sewing shop or a large manufacturing facility, investing in an industrial lockstitch machine is a wise choice that can pay off in the long run.

On the other hand, if you're willing to invest in a high-end single needle quilting machine, you can expect top-of-the-line features and superior quilting results. Brands like APQS, Gammill, and Handi Quilter offer premium quilting machines that are designed for professional use. These machines often come with advanced computerized controls, larger quilting areas, and faster stitching speeds for more efficient quilting.

1. Versatility One of the primary advantages of heavy-duty sewing machines is their versatility. They can sew through various materials, making them ideal for a wide range of projects. Whether you are working on fashion design, upholstery, or crafting sturdy outdoor gear, a heavy-duty machine can tackle it all with ease.

Furthermore, stitch machine embroidery designs are a time-saving option for those who want to create intricate designs quickly. With the ability to stitch out complex patterns in a fraction of the time it would take to do by hand, machine embroidery is a practical choice for both hobbyists and professionals. This efficiency allows you to produce more items in less time, making it easier to meet customer demands or create personalized gifts for loved ones.

Key Features and Benefits

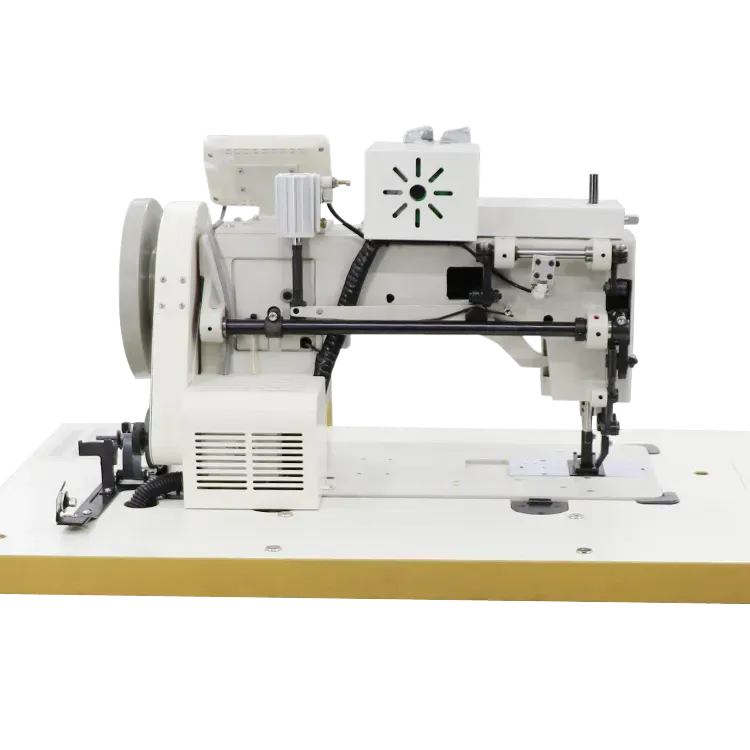

pp bag stitching machine

2. Adjust Tension Settings Every fabric type may require different tension settings on your overlock machine. Experiment with tension adjustments on scraps before sewing your main project to achieve the best results.

The Auto Cutter Sewing Machine Revolutionizing the Textile Industry

Benefits of Blind Stitching

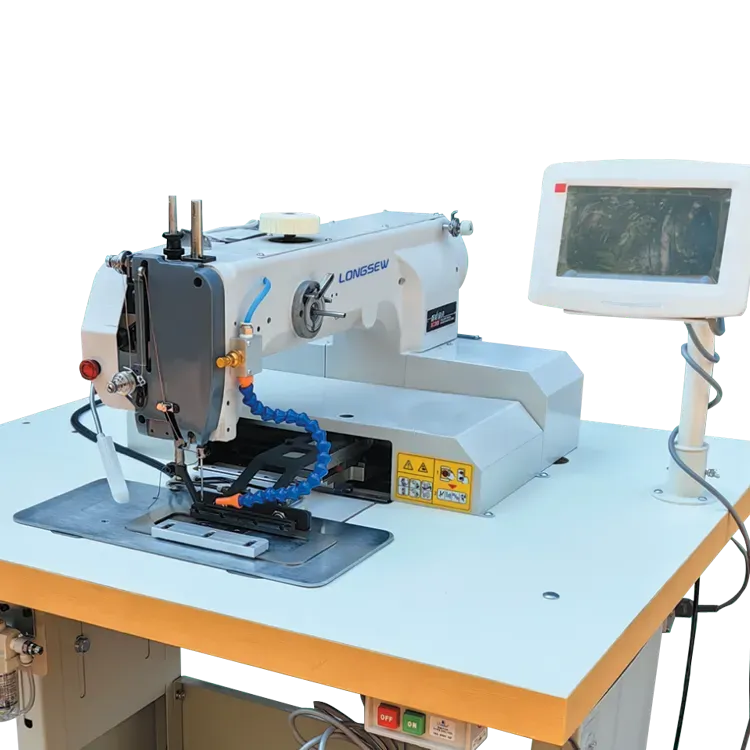

How Does a Lock Stitch Machine Work?

Moreover, automatic sewing machines contribute to cost efficiency. By minimizing labor costs and reducing fabric wastage through precision cutting and stitching, manufacturers can significantly lower their production expenses. This cost-effectiveness can translate into competitive pricing for consumers, making high-quality shirts more accessible. Furthermore, efficient production can lead to shorter lead times, allowing brands to introduce new collections and styles to the market promptly.

automatic sewing machine for shirts

Swing needle sewing machines are widely used across different sectors of the textile industry

. They hold significant value in garments production, upholstery work, and various crafts, providing precise stitching for a range of materials, from delicate fabrics to thicker textiles such as denim and canvas.2. Brand Reputation

Next comes the most critical part stitching. Hand stitching is primarily done using a method known as the saddle stitch, a technique that employs two needles and a single length of thread. This method is favored for its strength and durability, ensuring that the seams can withstand wear and tear over time. The process involves creating holes with an awl, allowing for precise and evenly spaced stitches, which contribute to the item’s overall aesthetic.