Links:

-

In essence, the house door bottom rubber seal is the unassuming workhorse of home maintenance. It requires minimal attention and care, asking only to be occasionally cleaned and inspected for wear and tear. Yet, it rewards us with significant improvements in comfort, energy efficiency, and overall home performance. Foam tape for doors is a versatile and effective solution for a variety of household issues. Whether you are trying to keep out drafts, block noise, or prevent insects from entering your home, foam tape can provide a quick and easy fix. This simple yet effective product is easy to install and can make a big difference in the comfort and energy efficiency of your home.

Zero leak mechanical seals are engineered to completely eliminate leakage, even under high pressure and fluctuating temperatures. These seals use advanced materials and designs to ensure a perfect fit between the sealing surfaces, reducing the chances of fluid migration. Unlike traditional seals that may require frequent maintenance and replacement, zero leak seals offer a long-lasting solution that enhances the durability and reliability of machinery.

In conclusion, an under door strip may seem like a small and insignificant accessory, but its benefits are substantial. From improving insulation and reducing noise transfer to keeping out dust and pests, an under door strip can significantly enhance the comfort and efficiency of any indoor space. By investing in this simple yet effective solution, you can enjoy a quieter, cleaner, and more energy-efficient environment for years to come. So don't overlook the importance of an under door strip – it may be the key to a more comfortable and enjoyable living or working environment.

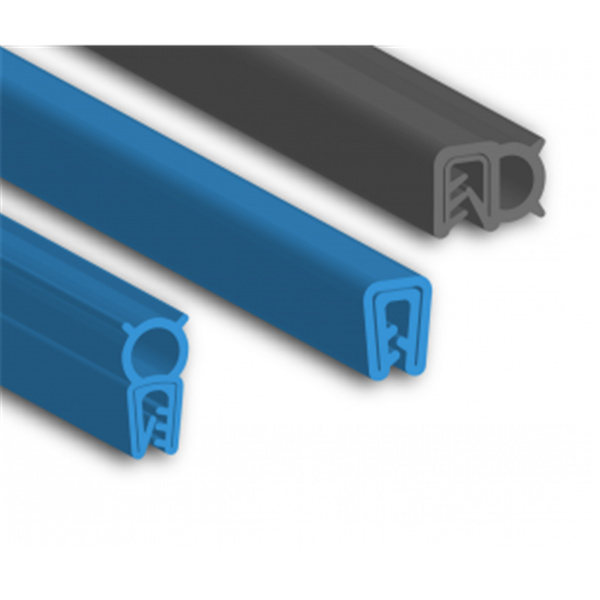

When it comes to working with glass, safety and aesthetics are of paramount importance. One key component that often goes overlooked is the use of rubber edge trim. This simple yet effective solution plays a significant role in protecting both the edges of glass and the people who handle it. In this article, we will explore the various benefits of rubber edge trim for glass and why it is an essential addition to any glass application.

Characteristics of EPDM Foam Rubber Seals

Interior door seals may seem like minor details in the grand scheme of home design and functionality, yet they play a pivotal role in creating a comfortable living environment. Often overlooked during construction or renovation, the significance of these seals cannot be understated. They contribute not only to energy efficiency but also to sound insulation and the overall aesthetics of a space.

Once installed, maintenance of the corner seals is relatively easy. Regular inspections can help identify wear and tear. If you notice any cracks, tears, or loss of flexibility, it’s advisable to replace the seals promptly. Keeping them in good condition ensures that they continue to perform effectively, protecting your home year-round.

1. Protects Contents The primary benefit of using seals in cabinets is the protection they offer. Whether it is moisture, dust, or pests, seals ensure that the contents remain safe and in optimal condition.

Finally, fire-rated door seals are specially designed to withstand heat and flames for a specified period, preventing the spread of fire. They are typically made from intumescent materials that swell when exposed to high temperatures, blocking gaps and expanding to several times their original thickness. 8. Finally, test the front door to make sure it opens and closes smoothly with the new seal in place.

5. Customization Rubber edge seals can be easily customized to meet specific application requirements. Manufacturers can create seals in various sizes, shapes, and colors, allowing for seamless integration into designs while maintaining aesthetic appeal.

2. Extrusion

In addition to improving energy efficiency and creating a more comfortable indoor environment, weather stripping for large gaps can also help to reduce outside noise and improve the overall security of a building. By sealing gaps in doors, you can help to keep out pests, dust, and other debris, as well as create a more secure barrier against intruders.Easy Installation and Maintenance

Additionally, the tape is available in different thicknesses and widths, catering to specific requirements. The black color is not just a stylistic choice; it also helps to conceal the tape when applied to darker surfaces, enhancing aesthetic appeal. Moreover, many types of black foam tape are resistant to moisture, UV rays, and environmental extremes, making them suitable for both indoor and outdoor use.

To extend the life of your car door window weather stripping, consider the following maintenance tips

- Aerospace In the aerospace sector, where precision and reliability are paramount, dry mechanical seals are used in landing gear and hydraulic systems, providing a secure barrier against leaks while ensuring optimal performance under extreme conditions.

What is a Bottom Door Frame Seal?

Dense foam strips also find applications in healthcare and rehabilitation. Cushioned support is critical for patients with mobility challenges or those recovering from surgery. Dense foam strips can be shaped into orthotic devices, enabling customized support and comfort. They also serve as padding for wheelchairs, braces, and other mobility aids, ensuring that individuals receive the necessary support while minimizing discomfort.

1. Energy Efficiency One of the most significant advantages of installing weather stripping is the improvement in energy efficiency. By sealing gaps around windows, you prevent heated or cooled air from escaping. This means your heating and cooling systems do not have to work as hard, leading to lower energy bills. According to the U.S. Department of Energy, sealing air leaks can save homeowners up to 20% on their energy bills.

Application Tips for Car Door Seal Adhesive

Double door weather stripping is a topic that may seem mundane, yet it holds significant importance in the realm of home insulation and energy efficiency. This unassuming component plays a crucial role in maintaining a comfortable indoor environment while keeping energy costs at bay.

5. Foam Seals

Why Use Foam Tape for Windows?

Noise Reduction

Moisture Control

4. Easy to Use The application of foam tape is straightforward and doesn't require special tools or equipment. This user-friendliness makes it a go-to solution for DIY enthusiasts and professionals alike.

5. Durability Made from high-quality materials, most expandable foam weatherstrips are designed to withstand extreme temperatures and weather conditions. They resist cracking, peeling, and deterioration, which ensures long-lasting performance that can hold up for many years without needing replacement.

Installing a door strip bottom can be a straightforward DIY project. Here’s a basic guide

door strip bottom

One of the primary benefits of foam strip adhesive is its cushioning effect. The foam material absorbs shocks and vibrations, making it ideal for applications that require protection against impacts and movement. This characteristic is particularly valuable in automotive and aerospace industries, where components must withstand constant motion and environmental changes.

One of the most iconic animals that call the seal edge home is, of course, the seal. Seals rely on the ice edge for resting, breeding, and hunting. They use the ice as a platform to haul out and bask in the sun, and also as a safe refuge from predators such as polar bears and orcas.

What are Car Body Side Protection Rubber Strips?

Another significant advantage of high-quality car door seal trim is its ability to reduce noise levels within the cabin. Outside noises, such as traffic, construction, or even the sound of wind, can be distracting during drives. Well-fitted seals can dampen these external sounds, creating a quieter and more enjoyable driving experience. This is especially valuable for long trips where driver fatigue can be exacerbated by constant background noise.

3. Clean the Surface Once the old stripping is removed, use a cleaning cloth to wipe down the area. Ensure that it is free of dirt, debris, and old adhesive residue for the best seal.

4. Magnetic Seals These seals use magnetic attraction to create a tight fit around the door frame. They are often found in storm doors or screen doors and can offer superior sealing.

Overall, foam door seals are an essential component for any building looking to improve energy efficiency, reduce noise levels, and increase overall comfort. With their easy installation, durability, and affordability, foam door seals provide a simple yet effective solution for sealing gaps around doors and frames. Whether you are looking to keep out drafts, insects, or noise, foam door seals are a practical and efficient option to consider. Door bottom sealing strips are an essential component for any home or building, helping to provide protection against drafts, dust, water, and pests. The guard protects your interior space from outside elements, ensuring a comfortable and energy-efficient environment. One of the main benefits of self-adhesive foam insulation strips is their simplicity of use. The adhesive backing makes them easy to attach to any surface, whether it be windows, doors, or other openings. This means you can quickly and easily insulate your space without the need for complicated tools or professional help. No matter what type of weather stripping you choose, it's important to make sure that it is installed correctly to ensure maximum effectiveness. Be sure to clean and dry the surface before applying the weather stripping, and make sure that it is pressed firmly into place to create a tight seal

exterior door weather stripping. Check the weather stripping regularly for signs of wear and tear, and replace it as needed to keep your doors sealed up tight. 1/2 inch weather stripping is a type of material that is commonly used for sealing gaps between doors and windows. It is typically made of rubber or foam, and its thickness of 1/2 inch provides excellent insulation and protection against the elements. This weather stripping is easy to install and can be cut to size to fit any door or window.

Mechanical seals are vital components in oil pumps, providing essential functions that enhance efficiency, safety, and reliability. Understanding their design, types, and maintenance can significantly impact the performance of pumping systems, protecting both the environment and the investment in infrastructure. As industries evolve and demands increase, the development of more advanced mechanical seals will continue to be a focal point in engineering, providing even better solutions for oil transport and processing.

2. Rubber Weather Stripping This is the most popular choice for modern cars due to its durability and flexibility. Rubber provides an excellent seal against water and noise while also withstanding various weather conditions.

weather stripping door seal strip car

Excessive road noise can be a significant nuisance during drives, particularly on long journeys. High-quality front windshield weather stripping helps reduce this noise by creating a barrier that absorbs sound waves, resulting in a quieter cabin environment. This feature is especially appreciated by those who frequently travel or commute long distances.

What is Foam Window Weatherstrip?

Choosing the Right Foam Tape

Advantages of Foam Tape

Energy Efficiency

There are several types of mechanical seals available for oil pumps, each suited for different applications

oil pump mechanical seal

Understanding Weather Stripping