Links:

-

42% Growth in Tomato Cages A Modern Agricultural Revolution Automotive Industry In the world of mechanical engineering, the conical extension spring is a remarkable piece of equipment that has revolutionized the way forces are absorbed and released in various applications. This unique type of spring, characterized by its tapering coils that decrease in diameter from one end to the other, offers several advantages over traditional cylindrical springs. Secondly, the spring rate is another critical factor. It defines how much the spring will compress or extend per unit of force applied. A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility

A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility

A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility A higher spring rate indicates a stiffer spring, while a lower rate means more flexibility coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery. Secondly, the size and dimensions of the sheet contribute to the pricing. Sheets with larger dimensions or thicker wires require more material and energy to manufacture, thus increasing the cost. The mesh opening size also impacts the price; smaller openings generally require more precision and time in the welding process, which can lead to a higher price. Despite its many benefits, the maintenance of a galvanized wire fence is relatively low. Regular cleaning to remove dirt and debris is usually sufficient, with occasional touch-ups of the zinc coating if needed. This low maintenance requirement further contributes to its overall cost-effectiveness. The aesthetic appeal of square metal grid panels should not be overlooked. Their geometric pattern adds a contemporary touch to any space, suiting both minimalist and industrial design styles. They can be powder-coated in a range of colors, allowing for customization to match the existing decor or to create a striking focal point. Furthermore, their sleek, linear appearance can visually expand a room, creating an illusion of spaciousness. Grid wall art display has become a popular and trendy way to showcase artwork in both homes and businesses. This modern and versatile display method allows for easy customization and rearrangement of art pieces for a dynamic and eye-catching presentation. One key advantage of stainless welded wire mesh lies in its strength and durability. The welding process not only secures the intersections of the wires but also enhances the overall robustness of the mesh. As a result, it can withstand considerable force and weight without deformation or breakage, which is paramount in construction projects like reinforced concrete, animal enclosures, or security barriers. 3

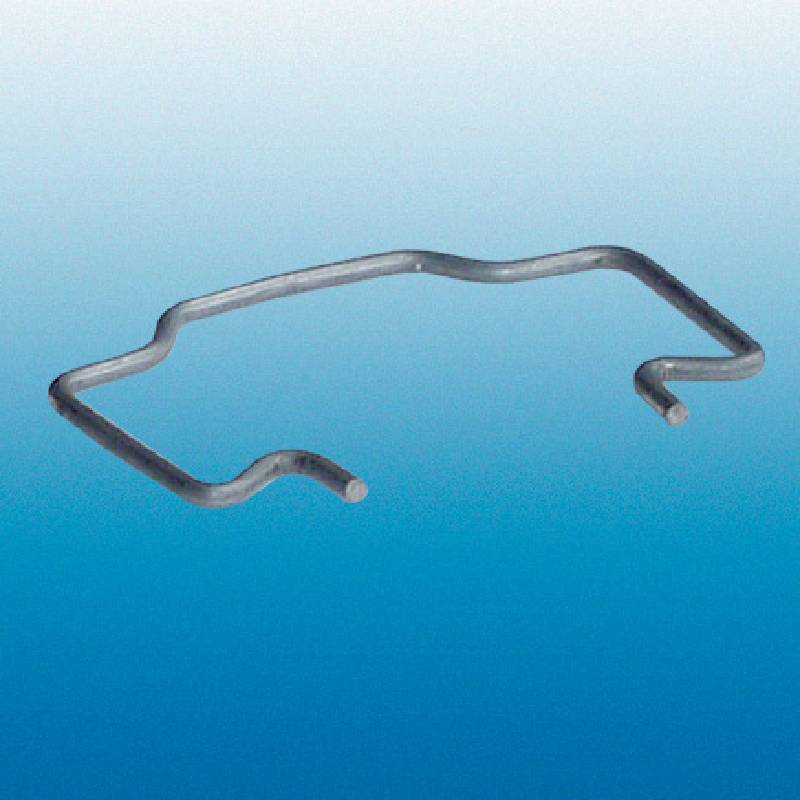

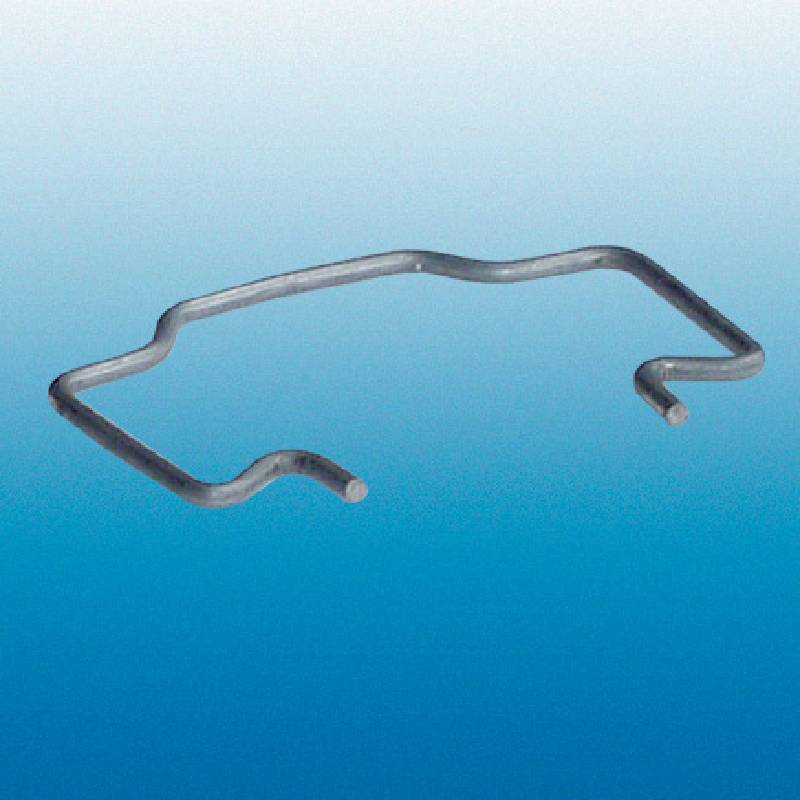

coil springs for sale. The choice depends on the specific application requirements, such as shock absorption in vehicles or tension control in machinery. Secondly, the size and dimensions of the sheet contribute to the pricing. Sheets with larger dimensions or thicker wires require more material and energy to manufacture, thus increasing the cost. The mesh opening size also impacts the price; smaller openings generally require more precision and time in the welding process, which can lead to a higher price. Despite its many benefits, the maintenance of a galvanized wire fence is relatively low. Regular cleaning to remove dirt and debris is usually sufficient, with occasional touch-ups of the zinc coating if needed. This low maintenance requirement further contributes to its overall cost-effectiveness. The aesthetic appeal of square metal grid panels should not be overlooked. Their geometric pattern adds a contemporary touch to any space, suiting both minimalist and industrial design styles. They can be powder-coated in a range of colors, allowing for customization to match the existing decor or to create a striking focal point. Furthermore, their sleek, linear appearance can visually expand a room, creating an illusion of spaciousness. Grid wall art display has become a popular and trendy way to showcase artwork in both homes and businesses. This modern and versatile display method allows for easy customization and rearrangement of art pieces for a dynamic and eye-catching presentation. One key advantage of stainless welded wire mesh lies in its strength and durability. The welding process not only secures the intersections of the wires but also enhances the overall robustness of the mesh. As a result, it can withstand considerable force and weight without deformation or breakage, which is paramount in construction projects like reinforced concrete, animal enclosures, or security barriers. 3 white grid for wall. **Furniture** Arrange furniture according to the grid system. This can be done by placing furniture at the intersection of grid lines, creating a sense of order and balance. Use clean lines and simple shapes for furniture to avoid cluttering the space. In the realm of home improvement, few elements can transform the aesthetic of a room quite like triangle wall ties. These ingenious devices, often overlooked or underappreciated, serve a dual purpose they add an elegant touch to your walls while also providing crucial structural support. Another type of snake spacer is the metal mesh spacer. This type of spacer is often used in larger enclosures or in situations where extra support is needed. The metal mesh spacer provides a sturdy barrier between the lid and the enclosure, ensuring that the lid stays secure and the snake stays safe

white grid for wall. **Furniture** Arrange furniture according to the grid system. This can be done by placing furniture at the intersection of grid lines, creating a sense of order and balance. Use clean lines and simple shapes for furniture to avoid cluttering the space. In the realm of home improvement, few elements can transform the aesthetic of a room quite like triangle wall ties. These ingenious devices, often overlooked or underappreciated, serve a dual purpose they add an elegant touch to your walls while also providing crucial structural support. Another type of snake spacer is the metal mesh spacer. This type of spacer is often used in larger enclosures or in situations where extra support is needed. The metal mesh spacer provides a sturdy barrier between the lid and the enclosure, ensuring that the lid stays secure and the snake stays safe

snake spacers. 6

The aesthetic appeal of black coated wire mesh is another reason why it is so popular. The dark color of the coating gives it a sleek and modern look, making it an attractive option for both indoor and outdoor applications. It can be used to enhance the appearance of buildings, gardens, and other outdoor spaces, adding a touch of style and sophistication. Another advantage of gold coloured craft wire is its affordability. Compared to solid gold wire, gold coloured craft wire is much more affordable, making it accessible to a wider range of crafters. This makes it an excellent choice for those who are just starting out in the world of jewelry making or crafting and want to experiment with different materials without breaking the bank. However, the wholesale iron wire industry also faces challenges, such as fluctuating raw material prices, environmental concerns, and the need for continuous technological advancements to enhance production processes. Despite these, the industry continues to thrive due to the relentless demand for iron wire across various sectors. The aesthetic appeal of black coated wire mesh is another reason why it is so popular. The dark color of the coating gives it a sleek and modern look, making it an attractive option for both indoor and outdoor applications. It can be used to enhance the appearance of buildings, gardens, and other outdoor spaces, adding a touch of style and sophistication. Mesh for Concrete Slab Overall, strong tomato cages are an indispensable tool for any tomato gardener looking to achieve a bountiful harvest of delicious and healthy fruits. By providing the necessary support and protection for your plants, tomato cages can help ensure that your tomatoes thrive and flourish throughout the growing season. Invest in a quality tomato cage today and watch your tomato plants reach new heights of success. One of the primary functions of reinforcement wire mesh panels is to provide structural support to concrete. When embedded within a concrete slab or wall, these panels help to distribute the weight of the concrete evenly, preventing cracks and other forms of damage. This reinforcement is especially important in areas with high levels of seismic activity, where structures need to withstand significant amounts of force. In conclusion, the white grid wall organizer is a stylish and functional solution for anyone looking to keep their home organized and clutter-free. Its versatility, durability, and ease of installation make it a must-have item for anyone who values aesthetics and functionality in their living space. So why wait? Invest in a white grid wall organizer today and transform your home into a clutter-free paradise!

The aesthetic appeal of black coated wire mesh is another reason why it is so popular. The dark color of the coating gives it a sleek and modern look, making it an attractive option for both indoor and outdoor applications. It can be used to enhance the appearance of buildings, gardens, and other outdoor spaces, adding a touch of style and sophistication. Another advantage of gold coloured craft wire is its affordability. Compared to solid gold wire, gold coloured craft wire is much more affordable, making it accessible to a wider range of crafters. This makes it an excellent choice for those who are just starting out in the world of jewelry making or crafting and want to experiment with different materials without breaking the bank. However, the wholesale iron wire industry also faces challenges, such as fluctuating raw material prices, environmental concerns, and the need for continuous technological advancements to enhance production processes. Despite these, the industry continues to thrive due to the relentless demand for iron wire across various sectors. The aesthetic appeal of black coated wire mesh is another reason why it is so popular. The dark color of the coating gives it a sleek and modern look, making it an attractive option for both indoor and outdoor applications. It can be used to enhance the appearance of buildings, gardens, and other outdoor spaces, adding a touch of style and sophistication. Mesh for Concrete Slab Overall, strong tomato cages are an indispensable tool for any tomato gardener looking to achieve a bountiful harvest of delicious and healthy fruits. By providing the necessary support and protection for your plants, tomato cages can help ensure that your tomatoes thrive and flourish throughout the growing season. Invest in a quality tomato cage today and watch your tomato plants reach new heights of success. One of the primary functions of reinforcement wire mesh panels is to provide structural support to concrete. When embedded within a concrete slab or wall, these panels help to distribute the weight of the concrete evenly, preventing cracks and other forms of damage. This reinforcement is especially important in areas with high levels of seismic activity, where structures need to withstand significant amounts of force. In conclusion, the white grid wall organizer is a stylish and functional solution for anyone looking to keep their home organized and clutter-free. Its versatility, durability, and ease of installation make it a must-have item for anyone who values aesthetics and functionality in their living space. So why wait? Invest in a white grid wall organizer today and transform your home into a clutter-free paradise! Lastly, location and logistics play a part. Shipping and handling fees, taxes, and import duties can significantly affect the final price, especially when dealing with international suppliers. In conclusion, the price of welded wire mesh per kg is a complex interplay of numerous elements, including raw material costs, wire gauge, welding process, mesh dimensions, finishing, and regional market dynamics. As a buyer, it's crucial to consider these factors when comparing quotes and making purchasing decisions. Understanding the factors that influence the price not only helps in budgeting but also ensures the procurement of the right quality and specification for your specific application. 2. Telecommunications The excellent electrical conductivity of annealed wire makes it ideal for use in telecommunications cables and wires. These stakes are designed to be durable and weather-resistant, making them ideal for outdoor use. Whether you're advertising a grand opening, promoting a sale, or directing traffic to an event, these stakes will keep your sign looking professional and organized. Made from high-quality materials, they can withstand the elements and remain standing for an extended period of time. Galvanized mesh fencing is made from high-quality steel that has been coated with a layer of zinc. This coating not only provides excellent corrosion resistance but also enhances the overall durability of the fence. The zinc coating acts as a barrier against rust, ensuring that the fence remains in top condition for many years to come. Properties of 5-Inch Coil Springs

Metal grid wall panels are a versatile and practical solution for organizing and displaying items in various environments. These panels are commonly found in retail stores, galleries, trade shows, and even home offices. With their grid-like design, they offer a convenient way to showcase products and make a statement in any space.

Conclusion The installation process of these ties requires precision and expertise. It involves drilling holes into the masonry, applying a suitable adhesive, and then inserting the tie to create a strong bond. This method ensures minimal disruption to the brick's surface, preserving both its appearance and structural integrity. In addition to its flexibility, metal stucco lath is also highly durable and resistant to corrosion, making it an ideal choice for outdoor applications. Its sturdy construction ensures that the stucco finish will remain intact and looking good for many years to come. Compression springs, an integral part of various mechanical and engineering systems, are a type of helical spring designed to oppose compression along its axis. In this discussion, we will delve into the specifics of a 2-inch compression spring, its design, function, and applications. 5. **Consider the viewer's perspective** Ensure that viewers can easily navigate the display and appreciate the images from different angles. In the world of gardening and agriculture, the importance of sturdy tomato stakes cannot be overstated. These essential tools play a pivotal role in supporting the growth and development of tomatoes, ensuring a bountiful harvest season after season. For those seeking high-quality, bulk tomato stakes, now is the perfect time to invest in these indispensable garden companions. The size and strength of the wire tie are determined by the specific requirements of the project Another advantage of portable chicken fencing is its versatility. It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens

It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens

It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens It can be used to create a variety of sizes and shapes of enclosures, depending on the needs of your chickens portable chicken fencing. For example, you can use it to create small pens for young chicks or larger enclosures for mature birds. You can also use it to create separate areas for different types of chickens, such as layers and broilers. The Double Helical Spring A Marvel of Engineering and Biology

portable chicken fencing. For example, you can use it to create small pens for young chicks or larger enclosures for mature birds. You can also use it to create separate areas for different types of chickens, such as layers and broilers. The Double Helical Spring A Marvel of Engineering and Biology 14 gauge galvanized wire

The price of welded steel mesh can vary depending on several factors, including its size, thickness, grade, and the type of steel used. Generally, the price per square meter increases with the size and thickness of the mesh. For example, a larger mesh with a higher gauge number will be more expensive than a smaller one with a lower gauge number. Additionally, the type of steel used can also affect the price, with stainless steel typically being more expensive than carbon steel. Next, think about the overall color scheme and theme of your grid wall art display. You can choose to mix and match different colors and styles of art for a eclectic look, or stick to a cohesive color palette for a more unified appearance. Experiment with different arrangements until you find a combination that best showcases your art collection. Furthermore, the white wire grid's contribution to the aesthetic value of a room cannot be understated. It adds a layer of texture and dimensionality to walls that might otherwise appear flat or dull. The interplay of light and shadow created by the grid's linear pattern introduces visual interest and depth, transforming what could be a mundane surface into a focal point of design. Unrolling the new mesh is where the art of replacement truly shines. The mesh must be tightly woven without distorting the weave's natural shape The mesh must be tightly woven without distorting the weave's natural shape The mesh must be tightly woven without distorting the weave's natural shape The mesh must be tightly woven without distorting the weave's natural shape

The mesh must be tightly woven without distorting the weave's natural shape The mesh must be tightly woven without distorting the weave's natural shape chain link fence replacement. A fence stretcher tool is often used to maintain the mesh's tension while attaching it to the newly installed posts. The challenge lies in achieving a balance between firmness and flexibility; too tight, and you risk breaking the wire, too loose, and the fence will sag or wobble.

chain link fence replacement. A fence stretcher tool is often used to maintain the mesh's tension while attaching it to the newly installed posts. The challenge lies in achieving a balance between firmness and flexibility; too tight, and you risk breaking the wire, too loose, and the fence will sag or wobble. Wall Ties, Snake Spacers, and Wire Spacers

3. Ease of Installation Due to its flexibility and ability to be formed to fit a range of shapes and sizes, WWF is relatively easy to install, reducing labor costs and project timelines. From that day on, the traveler never spoke of their experience in Bricktor's tunnels, for fear of what they had encountered in the darkness. And so the mystery of Bricktor, the town of bricks, remained intact, its secrets hidden away beneath the earth for eternity.

Enhance the integrity of the wall: the various parts of the cavity wall can be effectively connected together by binding, so that they can work together under the action of earthquakes, reducing the cracking and scattering of the wall.

When installing 250mm brick ties, it is important to follow the manufacturer's instructions and ensure proper alignment and spacing. Additionally, regular inspections and maintenance of the brick ties are essential to ensure their effectiveness and prevent any potential issues.

Masonry construction, while known for its aesthetic appeal and resilience, can be susceptible to stresses induced by environmental factors, loads, and time. The reinforcement of masonry joints serves as a preventive measure against these potential vulnerabilities. It involves the insertion of steel bars, wires, or fibers into the joints, creating a bond that distributes stress more evenly throughout the structure.