Links:

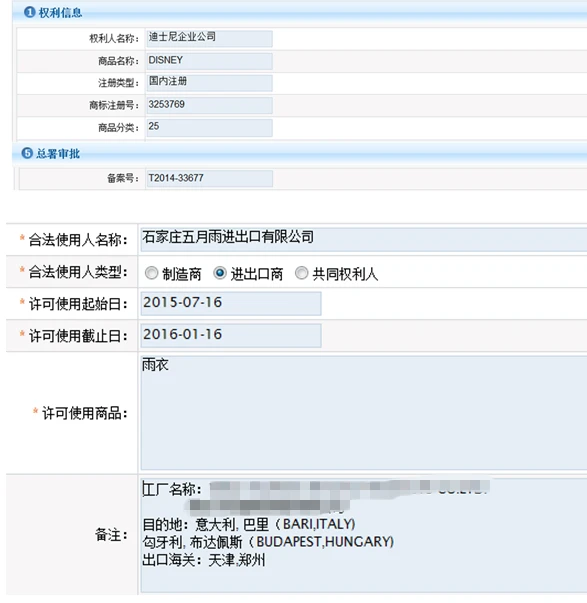

-

The real game-changer in these roofing nails is the incorporation of rubber washers. Made from high-quality rubber, these washers act as a cushioned barrier between the nail head and the surface it penetrates. They provide an additional sealant effect, enhancing waterproofing and preventing any potential leaks. This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact

This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact

This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact This feature is particularly crucial in regions with fluctuating weather conditions or heavy rainfall, ensuring the integrity of the roofing system remains intact bwg9x2.5 rubber washer roofing nails.

bwg9x2.5 rubber washer roofing nails. Chemical tanks can be made from various materials, including polyethylene, stainless steel, or fiberglass, depending on the chemical properties of the substances being stored. Each material has its advantages; for example, polyethylene is resistant to corrosion, while stainless steel is robust and capable of withstanding high temperatures. It’s crucial to select the appropriate tank material to ensure the safety and integrity of the stored chemicals.

The mesh size or hole diameter is another critical specification to consider

Hygiene and Safety

4. Customization Options Diamond razor wire fences can be customized to meet specific security needs. Property owners can choose from various heights and configurations, ensuring the fence aligns with the layout of the property while providing optimal security.

Sustainability is another crucial aspect driving the growth of the pallet nails industry in China. With increasing international pressure for environmentally friendly practices, many manufacturers are now adopting sustainable production methods. This includes using recycled materials in their nail production processes and minimizing waste. By prioritizing sustainability, Chinese manufacturers not only meet customer demands but also align with global trends advocating for environmentally responsible sourcing and production.

The Importance of Length per Roll

One of the most appealing aspects of galvanized wire mesh fencing is its low maintenance requirement. Unlike wooden fences that may rot or require regular staining, or vinyl materials that can fade and crack, galvanized wire fencing can withstand the elements for many years with minimal upkeep. A simple rinse with water and periodic inspections for damages are usually sufficient to keep it in good condition.

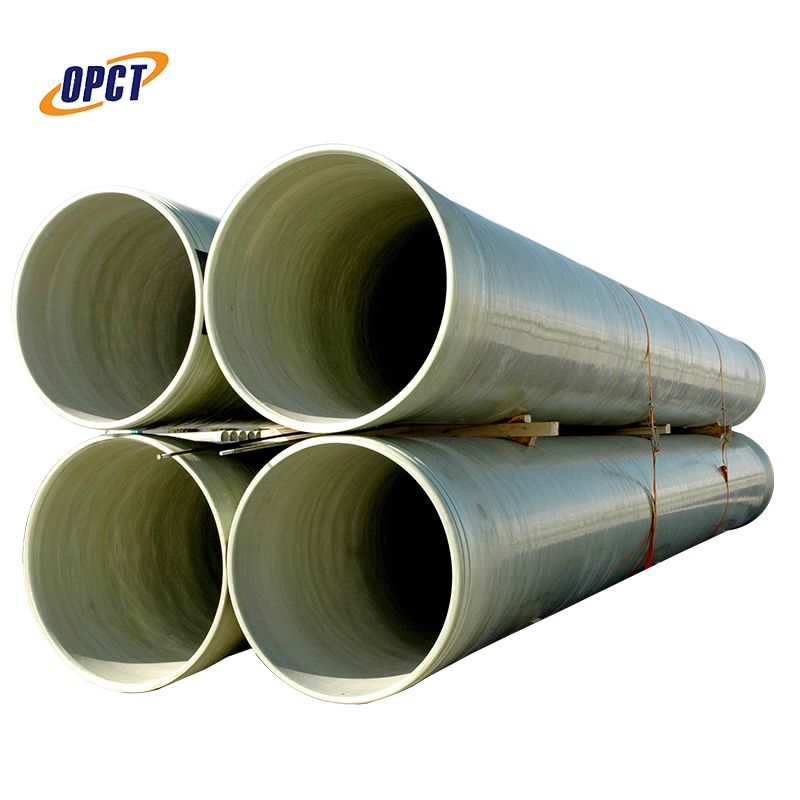

The Versatility and Benefits of 2-Inch Fiberglass Pipe

Safety and Security

* U.S. Plastic Corp. Known for its plastic products, USPC also carries a line of fiberglass tubing products for various applications.

With the many advantages, no wonder pultruded fiberglass profiles are widely adopted by designers, builders, and homeowners in a variety of applications, such as energy-efficient windows and doors, thermal breaks, window reinforcements, exterior trim, cladding, pergolas and arbors, columns, fencing and decking systems, and affordable modular housing systems.

In conclusion, API 209A serves as an essential guide for maintaining high standards in the design, construction, and operation of offshore pipelines. By emphasizing the importance of proper materials, regular maintenance, and comprehensive risk management strategies, API 209A plays a critical role in safeguarding environmental integrity and promoting safe practices within the oil and gas industry. As the industry continues to evolve, adhering to these standards will remain vital for ensuring both operational efficiency and environmental protection. The relevance of API 209A is underscored by its contribution to the sustainable management of offshore resources, underscoring the need for adherence to such guidelines in the quest for responsible energy production.

The mesh can come in various wire diameters and opening sizes, allowing it to cater to specific needs based on the material being processed and the intended separation requirements. The weaving patterns can also vary; for instance, the plain weave and twill weave are commonly used configurations that influence the strength and elasticity of the mesh.

One of the key features of chicken wire mesh is its durability. The galvanized wire used in its construction is resistant to rust and corrosion, making it suitable for outdoor use in all weather conditions. Additionally, the hexagonal shape of the mesh provides excellent strength and flexibility, allowing it to easily conform to uneven surfaces and withstand heavy loads.

Quality control is an integral part of the production in U-type nail factories. Each stage of manufacturing undergoes rigorous checks to ensure that the nails meet industry standards concerning size, strength, and finish. Factories often employ metallurgists and quality assurance engineers who test the tensile strength and resilience of nails to prevent defects that could compromise their utility.

In conclusion, selecting the right chicken wire mesh specifications is crucial for ensuring the safety and comfort of your poultry flock. By considering factors such as material, gauge, mesh size, and additional features, you can create an enclosure that meets your chickens' needs and provides peace of mind for you as a farmer. Remember to choose high-quality materials and consult with experts or experienced farmers to make an informed decision that benefits both you and your chickens.

Stainless steel is highly versatile, making it suitable for various water storage applications. It can be used for residential water tanks, irrigation systems, and industrial storage solutions. Additionally, its sleek and modern appearance adds aesthetic value to any setting, whether it’s a home, farm, or facility. Unlike bulky plastic containers that can be unsightly, stainless steel blends seamlessly into various architectural designs and environments.

What is FRP?

The Role and Impact of Square Wire Mesh Factories in Modern Industries

In terms of applications, black binding wire is instrumental in securing bundles of wires and cables, providing a neat and organized appearance while also protecting them from damage. It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical

It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical

It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical It is used extensively in the construction of transformers, motors, and generators, where reliable electrical connections are critical black binding wire factories. The wire's flexibility allows it to be twisted and tied without breaking, ensuring secure bonds that can withstand vibration and other mechanical stresses.

black binding wire factories. The wire's flexibility allows it to be twisted and tied without breaking, ensuring secure bonds that can withstand vibration and other mechanical stresses. When selecting a barbed wire roll, it’s essential to consider the perimeter of the area you intend to fence. For smaller properties, shorter rolls might suffice, but for larger områder, it’s usually more efficient and cost-effective to purchase longer rolls. This approach minimizes the number of splices required in the fencing, leading to a stronger, more durable barrier. Splicing two shorter lengths can create points of weakness, so fewer cuts and joints result in enhanced structural integrity.

barbed wire roll length

History of Diamond Mesh Fence Wire Fencing Factories

Applications Across Industries

Applications in Industry

In the realm of construction and industrial applications, fiberglass mesh has emerged as a vital component, particularly valued for its strength, durability, and resistance to environmental factors. The collaboration and competition between countries like China and Germany have paved the way for significant advancements in the production of fiberglass mesh. This article explores the innovations and key features of fiberglass mesh factories in both nations, shedding light on their contributions to the global market.

The Versatility and Strength of 5% 208% Fiberglass Rods An Engineering Marvel In conclusion, fiberglass septic tanks are a reliable and practical choice for homeowners in need of a wastewater storage solution. With their easy installation process, minimal maintenance requirements, and long-lasting durability, fiberglass tanks offer a cost-effective and efficient alternative to traditional concrete tanks. If you are considering installing a septic tank on your property, be sure to explore the benefits of fiberglass tanks for a reliable and long-lasting solution. The welded rabbit cage wire mesh also provides a secure platform for rabbit enrichment

Understanding Wire Mesh Length per Roll and Its Applications

GRP cable ladders are utilized in various sectors, including telecommunications, construction, energy, and transportation. In environments where corrosion is a significant concern—such as marine environments, chemical processing plants, and wastewater treatment facilities—GRP cable ladders offer a durable alternative. Their lightweight nature makes them easy to install and reposition, a highly beneficial feature in projects requiring flexibility and modular setups.

Additionally, solid fiberglass poles are known for their durability. Unlike metal poles, which can rust or corrode over time, fiberglass poles are resistant to the elements and can withstand harsh weather conditions without deteriorating. This makes them a reliable option for outdoor use, where they may be exposed to rain, snow, wind, and extreme temperatures.

Several factors dictate the appropriate dimensions for a fiberglass septic tank

Overall, diamond fence wire is a practical and reliable fencing material that offers durability, affordability, and versatility. Whether you are looking to secure your home, business, or outdoor space, diamond fence wire is a great option to consider. Its long-lasting performance, cost-effectiveness, and flexibility make it a popular choice for a wide range of applications. So if you are in need of a reliable and cost-effective fencing solution, consider using diamond fence wire for your next project.

- Furniture Manufacturing Many carpenters and furniture makers rely on these nails for sturdy joints and connections. Their strength ensures that furniture pieces maintain their shape and structural integrity throughout their use.

Chicken Wire Mesh Specifications A Comprehensive Guide

The fiberglass production process begins with raw materials, primarily silica sand, alumina, and various additives. These materials undergo a melting process at extremely high temperatures, typically around 1,400 to 1,600 degrees Celsius. The melted glass is then formed into fibers using several methods, including the traditional plunge method and more advanced techniques like the blow method. The choice of method often depends on the desired fiber diameter and application.

Understanding Concertina Wire Length per Roll and Its Applications

For businesses seeking to source copper square boat nails, it is crucial to stay informed about market trends and pricing dynamics. By understanding the influence of raw material costs, manufacturing efficiencies, and market competition, companies can make informed decisions that align with their operational needs and budget constraints.

Environmental Considerations

Coiled clout nails are distinguished by their unique spiral shape, which allows them to be driven into various materials with ease and precision. Made from high-quality steel, these nails boast exceptional strength, providing the durability needed for heavy-duty applications. The coiled design not only enhances the structural integrity of the fastening but also minimizes the likelihood of splitting wood, a common issue with traditional nails. This feature is particularly beneficial in scenarios where the integrity of the material is paramount.

One of the key advantages of fiberglass rods is their high strength-to-weight ratio. Despite being lightweight, fiberglass rods are incredibly strong and can withstand heavy loads without bending or breaking. This makes them an ideal choice for applications where weight is a concern, such as in the construction of lightweight structures or sport equipment.

Applications of 3% 204-Inch Fiberglass Rods

The process of creating copper square boat nails is a testament to traditional craftsmanship. Artisans nimbly forge each nail by hand, a practice that has been passed down through generations. This meticulous method not only reinforces the quality of each nail but also highlights the deep connection between the craftsmen and their materials. Each nail is infused with the artisan’s skill and dedication, ensuring that it meets the high standards expected in the maritime industry.

china copper square boat nail

In summary, binding galvanized wire is an invaluable material that plays a crucial role in various sectors in China. Its unique combination of corrosion resistance, strength, and versatility makes it an ideal choice for applications ranging from construction to agriculture and beyond. As industries continue to evolve and demand more durable and reliable materials, the importance of binding galvanized wire is likely to grow, solidifying its position as a key component in China’s manufacturing landscape.

The Significance of China Black Steel Nails in Construction and Industry