Links:

-

One of the key advantages of galvanized welded wire mesh is its strength and durability. The welding process creates a strong bond between the wires, making the mesh resistant to bending and breaking. Additionally, the zinc coating adds an extra layer of protection, making the mesh suitable for use in outdoor environments where it may be exposed to moisture and harsh weather conditions. Another benefit of using tall tomato cages is that they make it easier to access and harvest your tomatoes. With the plants supported and upright, it is much easier to see and pick the ripe fruits. This can save you time and effort in the long run, as you won't have to hunt around for hidden tomatoes or risk damaging the plants by bending them over to pick the fruit. In conclusion, overhead poultry netting is a multifaceted innovation that has revolutionized poultry farming. It offers protection, promotes health and productivity, simplifies management tasks, enhances biosecurity, and supports environmentally friendly practices. As we continue to seek out advancements in agriculture, the implementation of such solutions ensures that the future of farming is not only profitable but also humane and sustainable. The term soft in soft compression springs refers to the lower spring rate they possess compared to their stiffer counterparts. This lower spring rate allows them to deform more easily under pressure, making them ideal for applications where gentle force or a broader range of motion is required. The design of these springs typically involves coiled wires with larger diameters and fewer coils, ensuring a smoother and more controlled compression.

One of the key advantages of reinforcement wire mesh is its high strength-to-weight ratio. This means that it can provide the same level of support as heavier materials like rebar, but with less material usage and therefore reduced costs. Additionally, wire mesh allows for better distribution of forces, which helps prevent cracks and other forms of structural failure. In agriculture, galvanized wire fence is widely used for livestock containment due to its strength and flexibility. It can be easily shaped and configured to suit different topographies, making it suitable for both flat and hilly terrains. The wire's spacing can be customized to accommodate various animals, from sheep and goats to larger cattle, while still providing a secure barrier. Bed joint reinforcement typically involves the insertion of steel bars, wires, or mesh into the mortar beds between successive courses of masonry units. The reinforcement material, usually made from high-strength steel, is strategically placed to resist tension forces that could potentially damage the structure. This technique significantly improves the load-bearing capacity, shear resistance, and flexural strength of the masonry wall.

Overall, stainless steel mesh suppliers are crucial partners for industries looking for reliable and high-quality stainless steel mesh products. By working closely with these suppliers, businesses can ensure that they are using the right type of stainless steel mesh for their applications, resulting in improved efficiency, performance, and longevity of their equipment and structures.

2. Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them

Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them Place the Cage Before planting your tomato seedlings, place the cage around the spot where you plan to plant them installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow. One of the main advantages of black chain link fencing is its affordability. Compared to other fencing options such as wood or wrought iron, black chain link fencing is generally much more budget-friendly. This makes it an attractive option for property owners looking to secure their space without breaking the bank.

installing tomato cages. Make sure the cage is positioned securely in the ground to prevent it from tipping over once the plants start to grow. One of the main advantages of black chain link fencing is its affordability. Compared to other fencing options such as wood or wrought iron, black chain link fencing is generally much more budget-friendly. This makes it an attractive option for property owners looking to secure their space without breaking the bank. Galvanized iron wire plays a pivotal role in the construction industry due to its exceptional strength, durability, and versatility. Its application in tying rebar and securing structural materials ensures the stability and integrity of buildings and infrastructure. The cost-effectiveness and ease of use of galvanized iron wire further contribute to its widespread adoption in various construction projects, solidifying its status as a critical component in modern construction practices.

However, even with meticulous planning, success is never guaranteed. The thin metal stakes of innovation often come with inherent uncertainties The thin metal stakes of innovation often come with inherent uncertainties The thin metal stakes of innovation often come with inherent uncertainties The thin metal stakes of innovation often come with inherent uncertainties

The thin metal stakes of innovation often come with inherent uncertainties The thin metal stakes of innovation often come with inherent uncertainties thin metal stakes. Therefore, it is essential for organizations to cultivate a culture that embraces failure as a stepping stone to success. By learning from setbacks and viewing them as opportunities for growth, companies can build resilience and continue to push forward.

thin metal stakes. Therefore, it is essential for organizations to cultivate a culture that embraces failure as a stepping stone to success. By learning from setbacks and viewing them as opportunities for growth, companies can build resilience and continue to push forward. Adaptation to new design requirements: Possible changes in building use or updates to design standards may require replacement of connectors to meet new structural performance requirements.

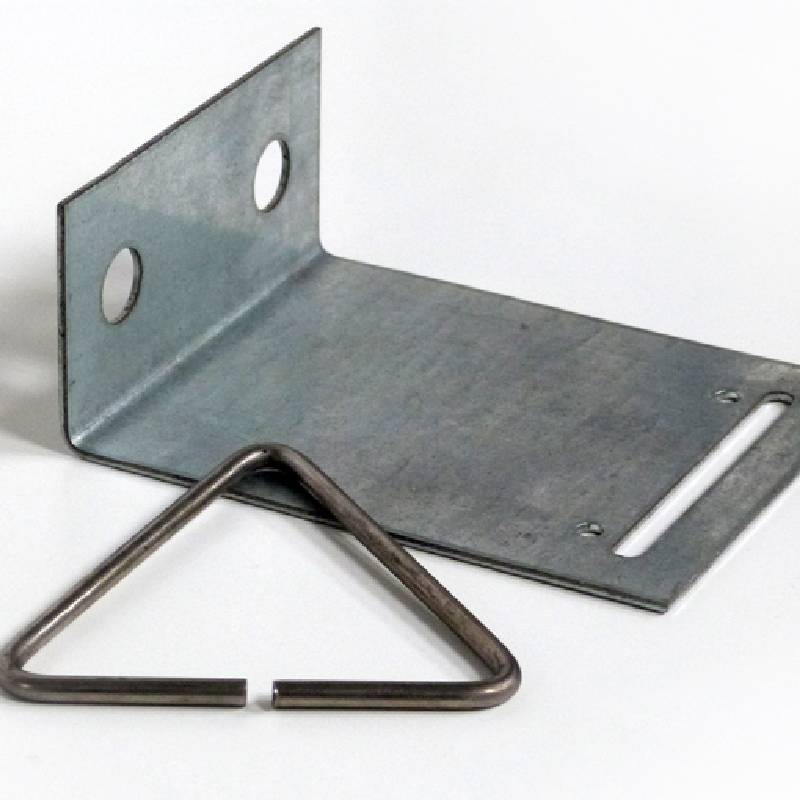

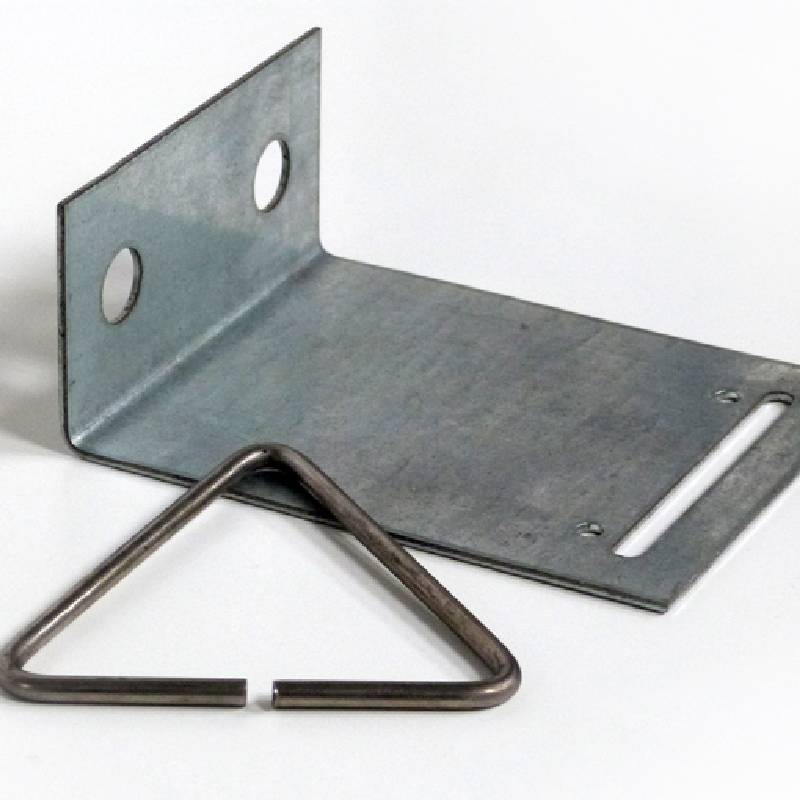

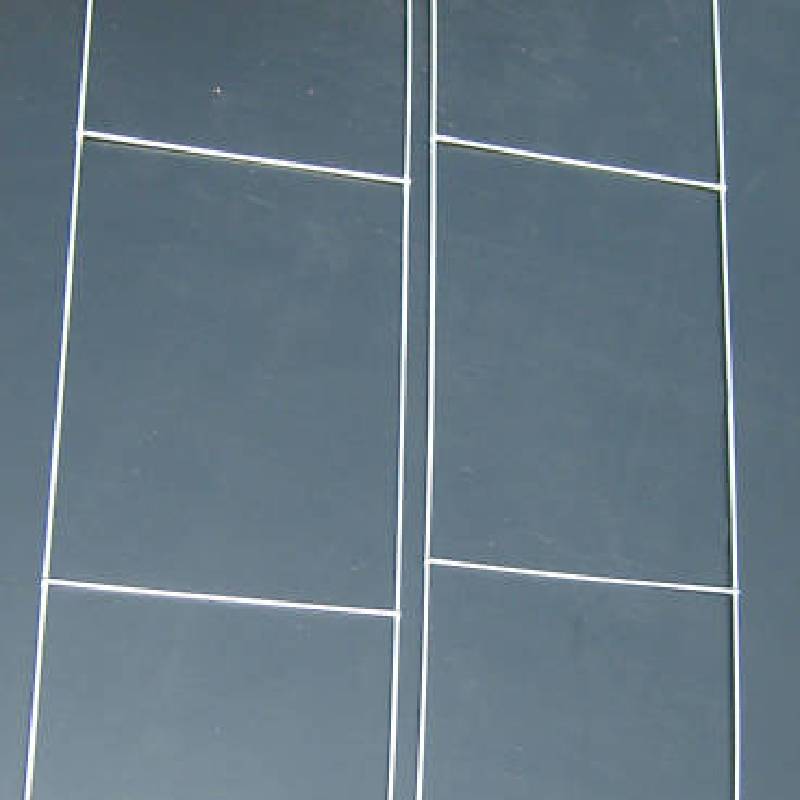

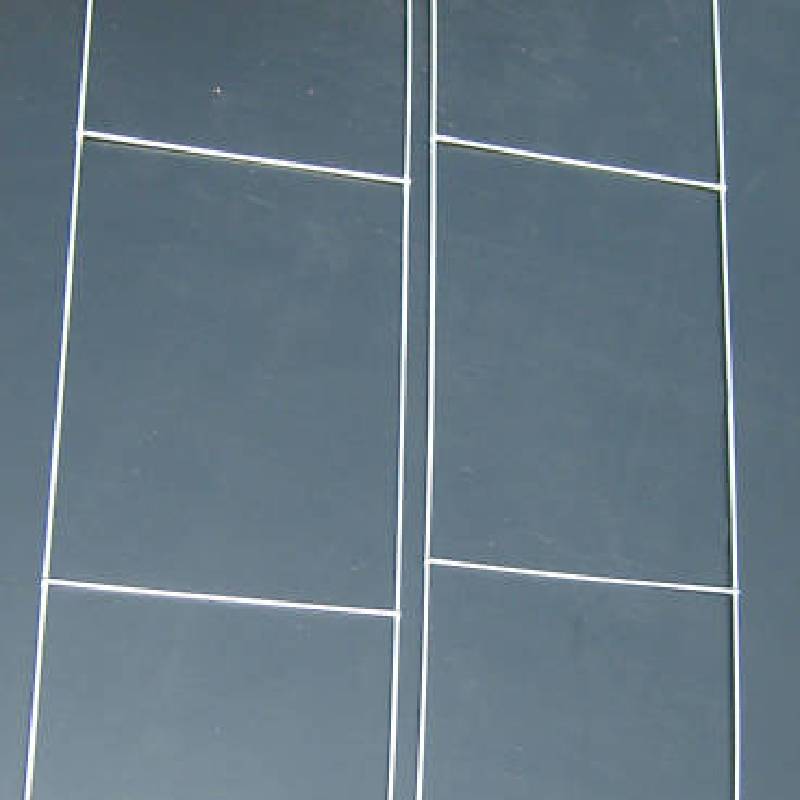

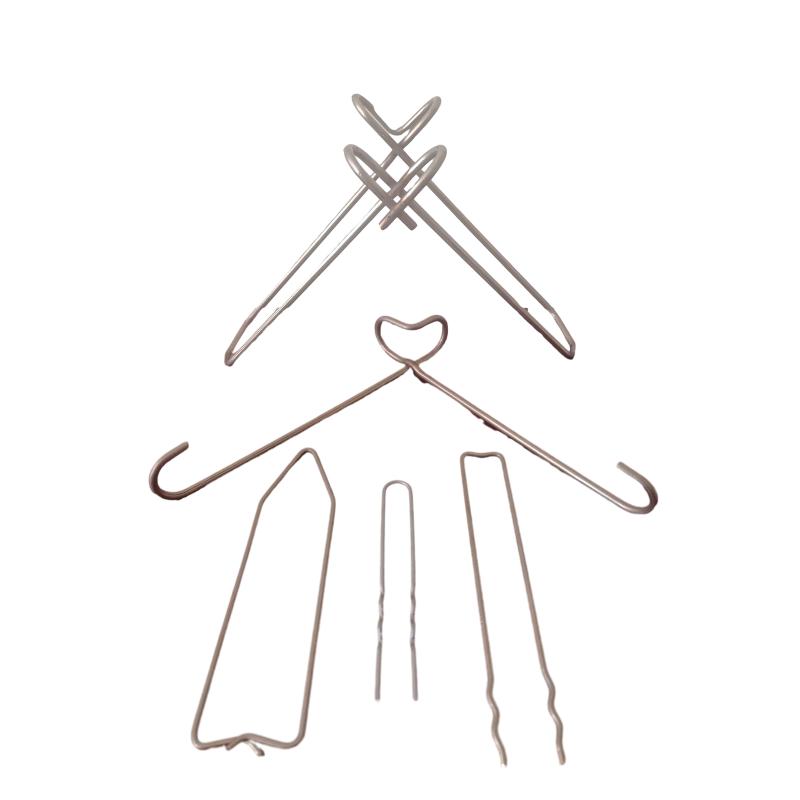

Brick tie spacing is an essential aspect of brickwork construction, often overlooked but crucial for the stability and durability of a building. It refers to the distance between the metal ties that connect the external brickwork to the internal load-bearing structure. These ties act as reinforcement, preventing the outer skin of bricks from moving independently and ensuring the overall structural integrity.Galvanized iron wire is a popular material among artists and DIY enthusiasts due to its unique combination of strength, flexibility, and resistance to corrosion. This versatile wire can be used to create a wide array of artistic and decorative projects, ranging from intricate sculptures to practical household items. Its durability ensures that creations maintain their form and integrity over time, making it an ideal choice for a variety of crafting applications.

To set up a hexagon tomato cage, simply place it over the plant when it is young and secure it to the ground with stakes or anchors. As the plant grows, gently guide the stems through the openings in the cage to provide support. Regularly check the plant to ensure it is growing vertically within the cage and make any adjustments as needed.Universal Coil Wire Springs, on the other hand, are versatile and can be used in a variety of applications. They are known for their ability to provide consistent force throughout the compression and extension cycles. This makes them suitable for use in car suspensions, industrial machinery, and even household items like recliners.

The primary function of brick ties is to transfer horizontal loads from the outer leaf to the inner leaf of the cavity wall. This is critical during high wind conditions or seismic activities, as they prevent the outer leaf from being blown out or collapsing. They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability

They also help distribute the weight of the structure evenly, ensuring its long-term stability They also help distribute the weight of the structure evenly, ensuring its long-term stability what do brick ties do. IBuffer buffer = IBuffer.allocate(inputVideo.length); In construction and engineering, flexible iron wire is often used for reinforcing concrete structures, creating support systems for plumbing and electrical wiring, and even for artistic design elements in buildings

what do brick ties do. IBuffer buffer = IBuffer.allocate(inputVideo.length); In construction and engineering, flexible iron wire is often used for reinforcing concrete structures, creating support systems for plumbing and electrical wiring, and even for artistic design elements in buildings

flexible iron wire. Its strength and malleability make it an ideal choice for these applications, as it can be easily shaped and manipulated to fit the specific needs of each project. Understanding the 2 Inch Compression Spring A Vital Component in Engineering Galvanization, the core of solid galvanized wire's properties, involves the application of a zinc coating to steel. The process, known as hot-dip galvanizing, sees the wire immersed in a bath of molten zinc, creating a metallurgical bond between the steel and the zinc. This bond provides a protective layer that safeguards the steel from the detrimental effects of oxidation, rust, and other forms of corrosion, ensuring a significantly longer lifespan compared to uncoated steel wires. Overall, strong tomato cages are an indispensable tool for any tomato gardener looking to achieve a bountiful harvest of delicious and healthy fruits. By providing the necessary support and protection for your plants, tomato cages can help ensure that your tomatoes thrive and flourish throughout the growing season. Invest in a quality tomato cage today and watch your tomato plants reach new heights of success. Durability is another key feature of concrete mesh panels. The reinforced nature of these panels ensures they can withstand harsh environmental conditions and resist cracking or breaking under pressure. They also exhibit excellent fire resistance, adding an extra layer of safety to buildings constructed with this material. Properties of 5-Inch Coil Springs Ease of installation is another aspect to ponder. While pre-assembled fencing kits can save time, they might be more expensive. DIY options like rolls of wire mesh can be customized to fit your specific needs but require more work. Ensure you have the necessary tools and knowledge before making a decision. Cavity wall ties are essential components in the construction of masonry walls, providing stability and integrity to the structure. These ties, made of stainless steel or galvanized steel, are installed between the inner and outer walls of a cavity wall to prevent them from separating due to thermal movement or other external forces. In this article, we will discuss the importance of cavity wall tie installation and provide a step-by-step guide on how to properly install these crucial components. Coil Springs for Sale Understanding Their Importance and Selection Criteria The aerospace industry also finds immense utility in HD Compression Springs. Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems

Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems

Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems Given the stringent requirements for lightweight yet robust components, these springs are integral to aircraft mechanisms, such as landing gear and control systems hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight. In the kitchen, stainless steel wire mesh is used to manufacture strainers, colanders, and baskets for。Its、。 In addition to its durability, permanent metal formwork can also help to streamline the construction process. Since the formwork remains in place after the concrete has been poured, there is less downtime between pours, allowing for faster overall construction. This can be especially beneficial for large-scale projects or projects with tight deadlines

hd compression spring. Their high-density construction ensures reliability under extreme conditions, crucial for safety in flight. In the kitchen, stainless steel wire mesh is used to manufacture strainers, colanders, and baskets for。Its、。 In addition to its durability, permanent metal formwork can also help to streamline the construction process. Since the formwork remains in place after the concrete has been poured, there is less downtime between pours, allowing for faster overall construction. This can be especially beneficial for large-scale projects or projects with tight deadlines

permanent metal formwork. Furthermore, steel mesh panels are widely used in the agricultural sector for animal enclosures and fencing. The gaps in the mesh can be customized to accommodate different sizes of livestock, ensuring safety while allowing for ventilation and visibility. In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards

In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards

In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards In addition, they are also employed in landscaping projects, forming robust yet visually appealing garden walls or tree guards steel mesh panels. In conclusion, coated tomato cages are more than just garden accessories; they are a testament to the harmonious blend of functionality and aesthetics in modern gardening. They simplify the process of nurturing tomato plants, allowing gardeners to focus on what truly matters - nurturing life and reaping the rewards of their labor. So, the next time you embark on your tomato-growing journey, remember, a good coated tomato cage is a gardener's best friend. Harnessing the Power of Bulk Stakes in Online Gaming Craft wire is available in an extensive range of gauges, with each gauge indicating its thickness. The lower the gauge number, the thicker the wire. So, a 16 gauge wire is neither too thin nor too thick, providing just the right rigidity for intricate designs without losing its shape or breaking easily. - **Fashion photography** Wire grid photo display can be used to showcase clothing and accessories in a creative and visually appealing way.

steel mesh panels. In conclusion, coated tomato cages are more than just garden accessories; they are a testament to the harmonious blend of functionality and aesthetics in modern gardening. They simplify the process of nurturing tomato plants, allowing gardeners to focus on what truly matters - nurturing life and reaping the rewards of their labor. So, the next time you embark on your tomato-growing journey, remember, a good coated tomato cage is a gardener's best friend. Harnessing the Power of Bulk Stakes in Online Gaming Craft wire is available in an extensive range of gauges, with each gauge indicating its thickness. The lower the gauge number, the thicker the wire. So, a 16 gauge wire is neither too thin nor too thick, providing just the right rigidity for intricate designs without losing its shape or breaking easily. - **Fashion photography** Wire grid photo display can be used to showcase clothing and accessories in a creative and visually appealing way. Custom Extension Springs

The beauty of rose gold craft wire lies not just in its appearance but also in its adaptability. It can be worked on with basic tools like pliers and wire cutters, making it accessible to beginners and professionals alike. Moreover, its affordability compared to solid rose gold materials makes it a popular choice for those seeking a luxurious look without the high-end price tag. 5. Connect the walls Once the ties are in place, connect the inner and outer walls using metal ties or straps. These connectors should be securely fastened to the walls and the ties to ensure maximum strength and stability. The Unparalleled Strength and Elegance of Diamond Wire Mesh Iron wires are typically made from high-quality materials such as copper or aluminum, which are known for their excellent conductivity. The wire is then coated with a protective layer to prevent corrosion and ensure durability. This coating also helps in safeguarding the wire from wear and tear, extending its lifespan and improving overall performance. Another advantage of welded reinforcing mesh is its cost-effectiveness. Compared to other reinforcement methods, such as rebar, welded mesh is more affordable and easier to install. It also allows for faster construction, saving time and labor costs in the long run. Additionally, welded mesh can be customized to fit the specific needs of a project, making it a versatile option for builders and contractors.2. The History and Evolution of Wire Grid Photo Display Another advantage of the 42% tomato cage is its durability

42 tomato cage. Made from high-quality materials, these cages are built to last. They can withstand harsh weather conditions and are resistant to rust and corrosion. This means that farmers can invest in these cages once and use them for multiple growing seasons, reducing their overall costs and increasing their profit margins. Our coil springs are available in a variety of sizes and styles to fit a wide range of vehicles

42 tomato cage. Made from high-quality materials, these cages are built to last. They can withstand harsh weather conditions and are resistant to rust and corrosion. This means that farmers can invest in these cages once and use them for multiple growing seasons, reducing their overall costs and increasing their profit margins. Our coil springs are available in a variety of sizes and styles to fit a wide range of vehicles coil over springs for sale. Whether you drive a car, truck, SUV, or van, we have the perfect springs to suit your needs. We also offer custom-made springs for those looking for a more personalized solution. One of the most common uses for heavy duty garden wire is for training and supporting climbing plants such as roses, tomatoes, and grapes. By attaching the wire to a wall or fence, you can create a strong support system for these plants to grow and thrive. This not only helps to keep your garden organized and looking tidy, but also ensures that your plants receive the necessary support to reach their full potential. Furthermore, in the realm of robotics and automation, these springs are integrated into intricate mechanisms, enabling precise movements and controlled actions in robotic arms or other devices. In addition to their ease of use and versatility, temporary cattle fences also help improve pasture health and productivity. By rotating cattle through different grazing areas, farmers can prevent overgrazing and ensure more even distribution of forage

coil over springs for sale. Whether you drive a car, truck, SUV, or van, we have the perfect springs to suit your needs. We also offer custom-made springs for those looking for a more personalized solution. One of the most common uses for heavy duty garden wire is for training and supporting climbing plants such as roses, tomatoes, and grapes. By attaching the wire to a wall or fence, you can create a strong support system for these plants to grow and thrive. This not only helps to keep your garden organized and looking tidy, but also ensures that your plants receive the necessary support to reach their full potential. Furthermore, in the realm of robotics and automation, these springs are integrated into intricate mechanisms, enabling precise movements and controlled actions in robotic arms or other devices. In addition to their ease of use and versatility, temporary cattle fences also help improve pasture health and productivity. By rotating cattle through different grazing areas, farmers can prevent overgrazing and ensure more even distribution of forage

temporary cattle fence. This not only benefits the cattle by providing them with a diverse and nutritious diet but also promotes regrowth and sustainability of the pasture.