Current location:

Links:

-

The Vital Role of FRP Storage Tanks in Modern Industry To understand the functioning of RTPP pipe, consider a pipeline carrying water from a source to a destination

Furthermore, the versatility of FRP allows for customization in design and capacity

Furthermore, the versatility of FRP allows for customization in design and capacity frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants. In the marine industry, fiberglass covers are used to protect boats from the elements. These covers shield against sun damage, prevent moisture accumulation, and reduce the risk of bird droppings or other debris staining the vessel's surface. Their custom-fit design ensures a snug fit, minimizing wind disturbance and potential chafing on the boat's finish. One of the most striking advantages of corrosion-resistant fiberglass is its longevity. Unlike traditional materials like steel or iron, which can rust and weaken over time, fiberglass maintains its strength and stability even under continuous exposure to corrosive elements. This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run

frp water tank. From small domestic units to large-scale industrial installations, FRP water tanks can be tailored to meet specific requirements, making them a versatile solution for various sectors, including agriculture, residential complexes, and industrial plants. In the marine industry, fiberglass covers are used to protect boats from the elements. These covers shield against sun damage, prevent moisture accumulation, and reduce the risk of bird droppings or other debris staining the vessel's surface. Their custom-fit design ensures a snug fit, minimizing wind disturbance and potential chafing on the boat's finish. One of the most striking advantages of corrosion-resistant fiberglass is its longevity. Unlike traditional materials like steel or iron, which can rust and weaken over time, fiberglass maintains its strength and stability even under continuous exposure to corrosive elements. This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run

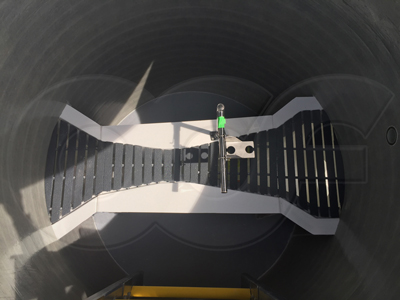

This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run This not only reduces maintenance costs but also increases the lifespan of structures, making it a cost-effective solution in the long run corrosion resistant fiberglass. Tunnel bench drilling bit is a critical tool used in the construction of tunnels. These bits are specifically designed to penetrate through hard rock and soil, making them essential for creating passageways and underground structures. The importance of tunnel bench drilling bits cannot be underestimated, as they play a crucial role in the efficiency and success of tunneling projects. In addition to their use in road construction and building construction, jack hammers are also used in mining and quarrying operations

corrosion resistant fiberglass. Tunnel bench drilling bit is a critical tool used in the construction of tunnels. These bits are specifically designed to penetrate through hard rock and soil, making them essential for creating passageways and underground structures. The importance of tunnel bench drilling bits cannot be underestimated, as they play a crucial role in the efficiency and success of tunneling projects. In addition to their use in road construction and building construction, jack hammers are also used in mining and quarrying operations jack hammer construction. They are able to break through tough rock formations, allowing for the extraction of valuable minerals and resources. This makes them an essential tool in the mining industry, where efficiency and speed are crucial. Moreover, these tanks can be customized to meet specific requirements. They can be manufactured in various sizes, ranging from small to large capacities, and can be designed with additional features such as access ports, agitation systems, or temperature control mechanisms. The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs

jack hammer construction. They are able to break through tough rock formations, allowing for the extraction of valuable minerals and resources. This makes them an essential tool in the mining industry, where efficiency and speed are crucial. Moreover, these tanks can be customized to meet specific requirements. They can be manufactured in various sizes, ranging from small to large capacities, and can be designed with additional features such as access ports, agitation systems, or temperature control mechanisms. The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs

The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs The lightweight nature of fiberglass also simplifies transportation and installation, reducing overall project costs fiberglass rectangular tank. In addition to their durability and versatility, frp hoods are also environmentally friendly. The production process of frp hoods requires less energy and resources compared to traditional metal hoods, making them a sustainable choice for eco-conscious industries. Another benefit of fiberglass chemical tanks is their flexibility. They come in a variety of sizes and shapes, allowing them to be customized to fit specific needs. This makes them particularly useful in industries where space is limited or where specialized storage requirements must be met. The Unyielding Shield Corrosion-Resistant Fiberglass Fiberglass pipes with large diameters have gained popularity due to their exceptional strength-to-weight ratio. Unlike metal pipes that can corrode over time or concrete pipes that can crack under pressure, fiberglass pipes resist corrosion and are highly resistant to both chemical and environmental degradation. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, thereby saving costs in the long run. A drill rod typically consists of a shaft with a cutting tip at one end and a shank at the other for attachment to a drill. The material used for drill rods can vary, but high-carbon steel is common due to its strength and ability to resist heat and wear. For more demanding applications, materials such as titanium or cobalt alloys may be used to enhance performance. There are two main types of tap drill bits straight shank and taper shank. Straight shank tap drill bits have a constant diameter along their entire length and are designed to be used in standard drill presses. Taper shank tap drill bits have a tapered shank that allows them to be used in adjustable drill presses or hand taps.

fiberglass rectangular tank. In addition to their durability and versatility, frp hoods are also environmentally friendly. The production process of frp hoods requires less energy and resources compared to traditional metal hoods, making them a sustainable choice for eco-conscious industries. Another benefit of fiberglass chemical tanks is their flexibility. They come in a variety of sizes and shapes, allowing them to be customized to fit specific needs. This makes them particularly useful in industries where space is limited or where specialized storage requirements must be met. The Unyielding Shield Corrosion-Resistant Fiberglass Fiberglass pipes with large diameters have gained popularity due to their exceptional strength-to-weight ratio. Unlike metal pipes that can corrode over time or concrete pipes that can crack under pressure, fiberglass pipes resist corrosion and are highly resistant to both chemical and environmental degradation. This durability ensures a longer lifespan, reducing the need for frequent replacements and maintenance, thereby saving costs in the long run. A drill rod typically consists of a shaft with a cutting tip at one end and a shank at the other for attachment to a drill. The material used for drill rods can vary, but high-carbon steel is common due to its strength and ability to resist heat and wear. For more demanding applications, materials such as titanium or cobalt alloys may be used to enhance performance. There are two main types of tap drill bits straight shank and taper shank. Straight shank tap drill bits have a constant diameter along their entire length and are designed to be used in standard drill presses. Taper shank tap drill bits have a tapered shank that allows them to be used in adjustable drill presses or hand taps. Food Processing: Used in food processing facilities due to its corrosion resistant and easy-to-clean properties. USDA/CFIA accepted and anti-microbial formulations provide additional benefits.

In conclusion, button bit manufacturers are an integral part of the construction and mining machinery ecosystem. Their work is critical in ensuring the efficiency, safety, and success of drilling operations worldwide. As technology advances and sustainability becomes a priority, these manufacturers continue to innovate, shaping the future of drilling technology. Fiberglass, a composite material made from fine glass fibers, offers exceptional thermal resistance, durability, and chemical stability. When used in pipe insulation fittings, these properties ensure that pipes maintain their optimal temperature, whether they're carrying hot or cold fluids. This is particularly crucial for applications where temperature control is vital, such as in industrial processes where overheating or freezing can lead to equipment damage or production disruptions. The Role of Frp Demister in Industrial Processes Furthermore, fiberglass tanks are relatively lightweight compared to their steel counterparts, making them easier to transport, install, and maintain. This can result in significant cost savings for businesses in terms of labor, equipment, and maintenance expenses

custom fiberglass tanks. Fiberglass tanks are also resistant to algae growth, minimizing the need for frequent cleaning and maintenance. In the 19th century, the industrial revolution brought about significant changes in the design and production of drill bits. Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges

Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges

Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges Advances in manufacturing techniques, such as casting and stamping, allowed for the mass production of drill bits with multiple cutting edges drill bits. This led to a significant increase in drilling speed and efficiency, making it possible to drill larger holes in less time. In the realm of modern industry, the significance of Fiber Reinforced Plastic (FRP) storage tanks cannot be overstated. These tanks, crafted from advanced composite materials, have revolutionized the way we handle and store liquids, gases, and other substances. Their exceptional strength, durability, and chemical resistance make them an indispensable tool for a wide range of applications across various sectors. In conclusion, cutting drill bits offer a convenient solution for those looking to streamline their drilling and cutting processes. By combining these two functions into one tool, they provide increased efficiency and versatility. Whether you're a professional contractor or a weekend hobbyist, investing in high-quality cutting drill bits can significantly improve your workflow and results.

drill bits. This led to a significant increase in drilling speed and efficiency, making it possible to drill larger holes in less time. In the realm of modern industry, the significance of Fiber Reinforced Plastic (FRP) storage tanks cannot be overstated. These tanks, crafted from advanced composite materials, have revolutionized the way we handle and store liquids, gases, and other substances. Their exceptional strength, durability, and chemical resistance make them an indispensable tool for a wide range of applications across various sectors. In conclusion, cutting drill bits offer a convenient solution for those looking to streamline their drilling and cutting processes. By combining these two functions into one tool, they provide increased efficiency and versatility. Whether you're a professional contractor or a weekend hobbyist, investing in high-quality cutting drill bits can significantly improve your workflow and results. Surface types:

Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating

Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating Next, the drill bit should be centered on the rod and the drill should be operated at a slow and steady speed to prevent overheating threaded rod drill bit.

threaded rod drill bit.