Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction

Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction Its ability to handle dynamic loads with ease makes it a preferred choice in industries like manufacturing, automotive, and construction sliding roller with steel housing. The design of a cast basket is a testament to human ingenuity. Its mesh allows water to flow through freely, reducing drag and disturbance to the water's natural state. The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish

sliding roller with steel housing. The design of a cast basket is a testament to human ingenuity. Its mesh allows water to flow through freely, reducing drag and disturbance to the water's natural state. The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish

The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish The sturdy frame, often made from wood or aluminum, provides stability while the handle, extending several feet, enables the angler to reach out without spooking the fish cast basket.

cast basket.

Steel or Iron Which is Stronger?

2. Condensation Control In climates with variable temperatures, condensation can be a significant issue, leading to mold and deterioration of building materials. By reducing the temperature differentials on the interior surfaces, thermal break profiles help minimize the likelihood of condensation forming on windows and doors.

thermal break aluminium profile

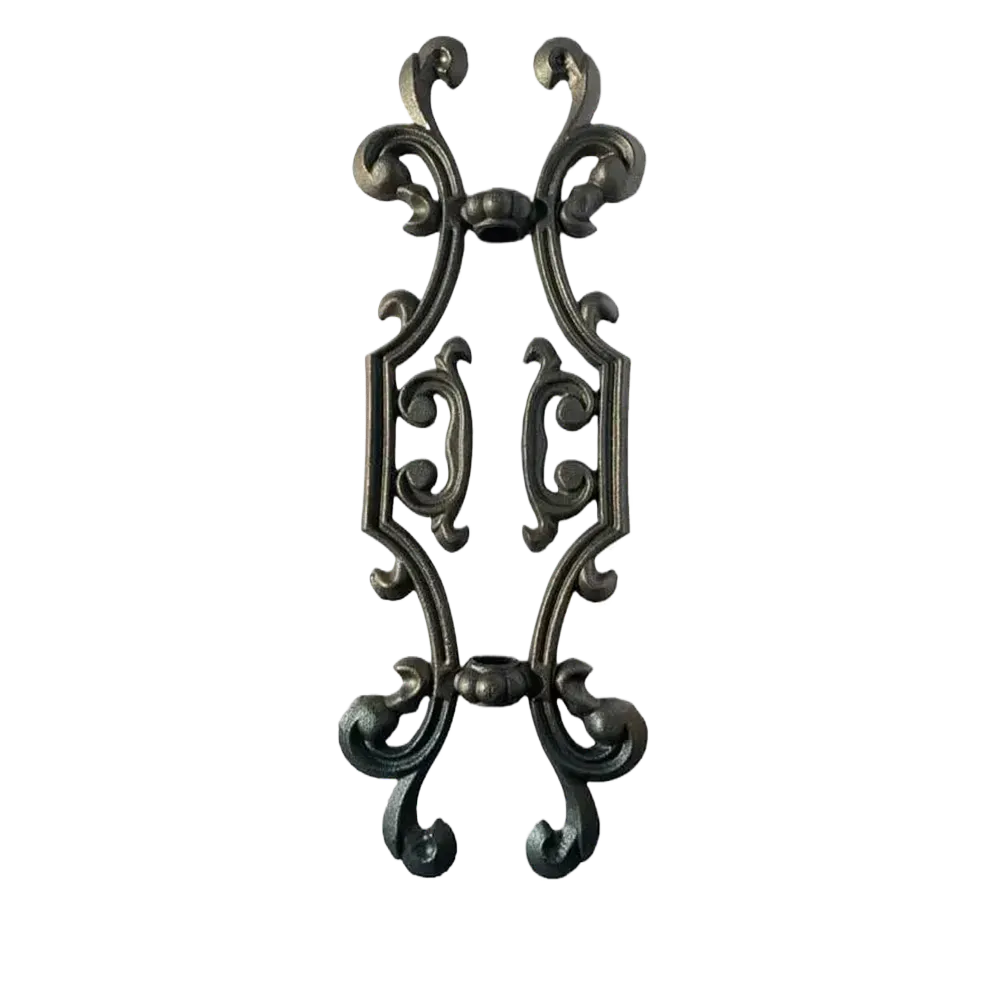

Investing in cast iron ornaments is investing in art that lasts. So, whether you're looking to enhance your home's decor, add a touch of vintage charm, or simply appreciate the craftsmanship of yesteryears, our collection of cast iron ornaments for sale offers a plethora of choices to suit every taste and preference. Embrace the beauty and resilience of cast iron, and let these ornaments bring a unique character to your living spaces. Sliding doors, with their sleek design and space-saving functionality, have become a popular choice for modern homes and offices. However, like any mechanical system, they require regular maintenance to ensure smooth operation. One critical aspect of this maintenance is adjusting the sliding door rollers.

You can attain this by sliding one feature over the other.

The aluminum profiles for doors and windows are made of 6-series aluminum alloy, and the aluminum-magnesium silicon is the main element of the 6-series aluminum alloy, and each element has a certain range of content. However, the price of various elements is inconsistent, and the lack of precious metal content is a major cause of poor profile quality. Only in strict proportion then can produce aluminum extrusions of excellent quality. The prepared raw materials are placed in an aluminum melting furnace to be melted, slag is discharged, cooled, and then cast aluminum ingots or bars are used for the production of aluminium profiles. If the exhaust is not ideal, the air bubbles in the aluminium profile will cause defects. The aluminium profiles for doors and windows are mainly made of 6063 grade aluminum alloy. If the aluminum extrusion manufacturer uses the national standard 6063 aluminum ingot, it will be guaranteed in terms of raw material quality.

The Debate of Doors vs

. Wheels A Look into the Numbers and ImplicationsAluminum, being a highly versatile material, is ideal for window frames due to its strength, durability, and resistance to corrosion. The extrusion process transforms molten aluminum into complex shapes, tailor-made for window frames, ensuring precision and consistency. This technique allows manufacturers to create intricate designs that not only cater to structural requirements but also enhance the visual appeal of a building.

When deciding on your materials, one of the first concerns you’ll likely have is wrought iron vs. aluminum fence cost.

Runner wheels, usually made from high-quality materials like stainless steel or nylon, are designed to bear significant loads while ensuring a quiet and smooth operation. They are mounted onto the bottom or top of the door, working in tandem with a track system to facilitate the door's movement along its path. The wheels' design is ingeniously engineered, incorporating ball bearings or roller mechanisms that reduce friction and increase durability. Finials are decorative ornaments that are often added to the tops of the posts or pickets to enhance the visual appeal of the fence. These ornamental elements can be simple and understated or elaborate and ornate, depending on the overall style of the fence. Finials should be securely attached to prevent them from coming loose or falling off. In conclusion, aluminum window extrusion profiles have revolutionized the window industry with their unique blend of form and function. They not only provide structural integrity and aesthetic appeal but also contribute significantly to energy efficiency and environmental sustainability. As we continue to push the boundaries of architectural design, aluminum window extrusions remain a preferred choice for architects, builders, and homeowners alike, shaping the future of modern construction.Various manufacturers price their specific aluminum profiles for windows and doors differently.

Surface treatment: This is very important because door and window profiles are subject to different surface treatments depending on the environment in which they are used. Generally, door and window profiles will be coated with fluorocarbon coating, powder coating, anodized, and electrophoresis. Among them, anodic oxidation is a standard surface treatment method. Through the electrolytic reaction in the electrolyte, an oxide film is formed on the surface of the aluminum alloy to protect the aluminum alloy material.Surface finish: This dramatically impacts the performance of doors and windows. If the surface finish is not good, the corrosion resistance, wear resistance, oxidation resistance and other properties of doors and windows may be reduced.

Size: There are two types of door and window profile sizes, one is standard size and the other is customized size. We can make custom sizes according to your project needs.

Quality standards: There are different quality standards for door and window profiles. According to your local requirements, you can refer to the standards of profiles and provide requirements to the manufacturer. Or you can take the profile's weight, appearance, hardness, strength, and oxide film.

thickness as a reference direction and coordinate with the aluminum material manufacturer.

Thickness: This is one of the important indicators of doors and windows, which is directly related to the safety performance of doors and windows. The wall thickness of the main stress-bearing rods of aluminum alloy doors and windows should be more than 1.4 mm. The wall thickness of the main stress-bearing rods of aluminum alloy doors should be more than 2.0 mm. The tensile strength should reach 157N/mm.

Type: There are many types of profiles now which can fully meet the needs of any project. Generally, different use environments will have specific profiles to choose from.

For example:

Standard aluminum door and window profiles

Thermally broken aluminum door and window profiles

Sliding aluminum windows and doors profiles

Casement aluminum windows and doors profiles

Folding aluminum windows and doors profiles

Soundproof aluminum alloy profile

Generally, the profile configuration should be selected according to the project requirements when choosing aluminum materials for doors and windows. If you have special requirements, you can communicate with the aluminum profile manufacturer. Now the technology from extrusion to processing door and window profiles is very mature. As a professional aluminum factory, we have produced aluminum for any project. We are fully confident in producing aluminum for any project.