Links:

The versatility of the V-belt B60 makes it suitable for a wide array of applications. It is commonly found in industrial machinery, agricultural equipment, and automotive systems. In manufacturing settings, it is used to drive generators, compressors, and conveyor belts, facilitating the movement of materials and power between machines.

8PK belts are found in a wide range of vehicles, from compact cars to SUVs and trucks. They are highly versatile and can be used in various applications, not just in cars but also in industrial machinery and generators. Because of their design and ribbed structure, they provide superior performance across various load conditions, ensuring longevity and efficiency.

Applications of the 6PK 2140/6PK Belt

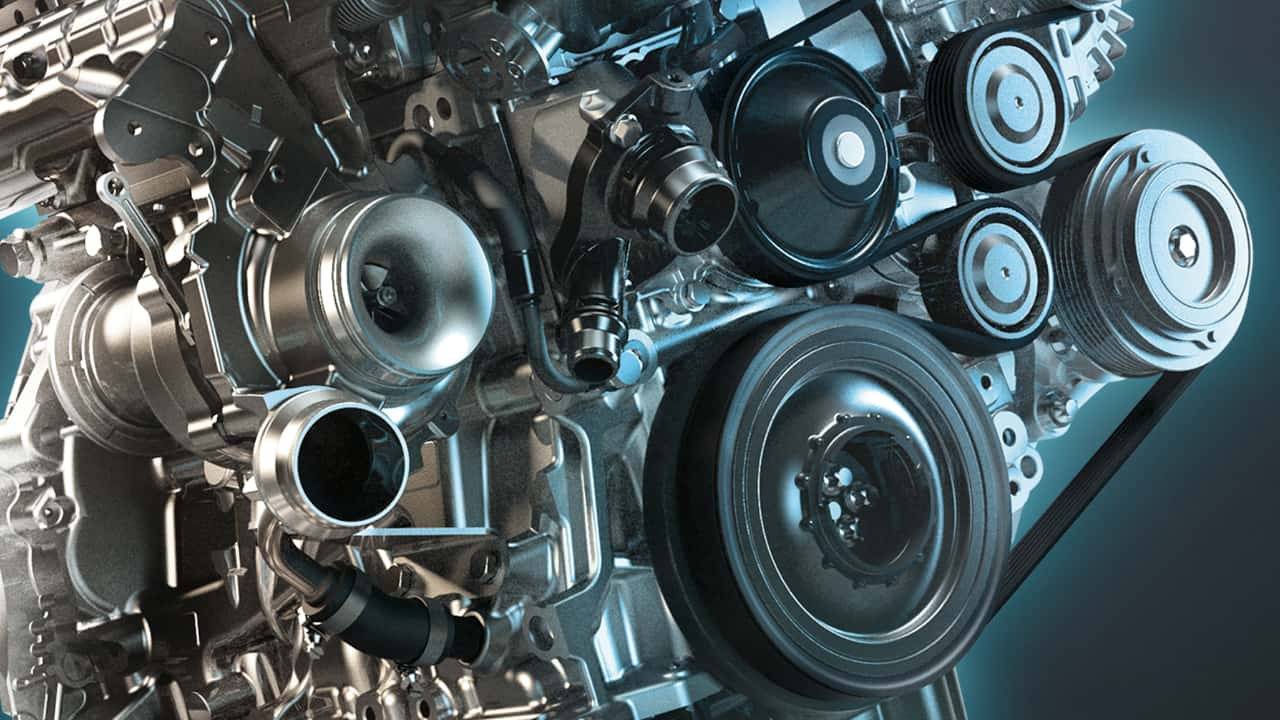

A serpentine belt is a long, winding belt that snakes around multiple pulleys in the engine. Unlike older vehicles that used several separate belts, most modern vehicles employ this single belt design, which simplifies both the supporting structure and the maintenance required. The serpentine belt works by transferring power from the engine crankshaft to various engine components, thereby ensuring that all necessary systems operate efficiently. This all-in-one belt design also reduces weight and the number of parts that could potentially fail.

What is a V-Belt?

The Importance of Timing Belts in Automobiles

How to Maintain Auto Parts

In conclusion, the timing belt is a vital element of any vehicle's engine, playing an integral role in the harmonious operation of its components. Understanding its function, adhering to maintenance schedules, and recognizing the signs of wear can help vehicle owners avoid significant issues down the road. By taking a proactive approach to timing belt care, you can enhance your vehicle's performance, extend its life, and ultimately save on costly repairs. Prioritizing regular maintenance and being aware of your timing belt's condition can ensure that your engine runs smoothly and efficiently for years to come.

Timing Belt Replacement Costs

4. Testing Methods Established testing methods outlined in standards provide manufacturers with guidelines for evaluating performance characteristics of V-belts, including traction, endurance, and heat resistance. For example, the International Organization for Standardization (ISO) has specific tests in place to assess these properties, ensuring that only the highest quality belts reach the market.

- Reduced Puffiness The vibration and heat work together to minimize puffiness, particularly around the eyes and cheeks. This allows for a more rested and vibrant look.

PK 708, Türkiye'nin büyüyen enerji ihtiyacını karşılamak ve sürdürülebilir enerji çözümleri geliştirmek amacıyla yapılan yenilikçi projelerden biridir. Bu projenin temel amacı, yenilenebilir enerji kaynaklarını etkili bir şekilde kullanarak, çevresel etkileri minimize etmek ve fosil yakıtlara olan bağımlılığı azaltmaktır.

Moreover, Thailand's strategic location in Southeast Asia has made it an attractive logistics hub. The establishment of extensive transportation networks has further fueled the growth of industries reliant on v-belts. From manufacturing plants to agricultural machinery, v-belts are crucial in facilitating smooth and efficient operations.

When choosing between a motorcycle primary chain and belt, the decision ultimately hinges on the rider's priorities and riding style. For riders who value performance, strength, and the ability to adjust their drivetrain, chains may be the better option. Conversely, for those who prioritize low maintenance, comfort, and a quieter ride, belts may be the ideal choice. Understanding the intricacies of these systems can help riders enhance their motorcycle experience, ultimately allowing for enhanced adventures on the open road. Regardless of the choice, both systems play a critical role in ensuring that motorcycles perform optimally, delivering the exhilarating experiences that riders cherish.

One of the standout benefits of flat webbing slings is their high strength-to-weight ratio. This property allows operators to lift heavy loads with minimal equipment, facilitating efficient operations. For instance, a flat webbing sling rated for 5 tons may weigh only a few pounds, making it manageable for workers to handle.

To ensure optimal performance, proper installation and maintenance of the 135J6 poly V belt are crucial

- Engine misfires or rough idling

The motorcycle chain belt emerged as a unique accessory that married functionality with aesthetics. Crafted from actual motorcycle chains, these belts echo the raw, industrial nature of the vehicles they reference. The transition from practical motorcycle maintenance to a fashionable belt is a testament to human ingenuity and the desire to repurpose materials in innovative ways.

The tensioner belt pulley may not be the most glamorous component of an automobile, but its significance cannot be overstated. As vehicles become increasingly complex, the importance of every single part, including the tensioner belt pulley, becomes more pronounced. By understanding its function and recognizing the signs of potential failure, vehicle owners can ensure their engines operate smoothly and efficiently. Regular maintenance and timely replacement can save money, reduce the risk of breakdowns, and extend the life of your vehicle. Whether you are a seasoned mechanic or a new car owner, keeping an eye on the tensioner belt pulley can contribute significantly to your vehicle’s overall performance.

A timing belt is a rubberized belt that synchronizes the rotation of the crankshaft and camshaft in an engine. It is essential for maintaining the engine’s timing, ensuring that the valves open and close at the proper intervals in relation to the position of the pistons. A well-functioning timing belt results in the smooth operation of an engine, while a worn or broken timing belt can lead to catastrophic engine failure.

Maintenance Tips

What is a Serpentine Belt?

Часавы Ремень для 3D Прынтэра Як Выбраць і Абслугоўваць

2. Shop Around Don’t settle for the first estimate you receive. Getting quotes from multiple mechanics or auto shops can help you find a better price.

4. Low Maintenance Toothed belts do not require lubrication, reducing maintenance time and costs associated with oiling or greasing.

The automotive industry has undergone significant transformations since the invention of the automobile, and at the heart of this evolution lies the often-overlooked world of auto parts. From the early days of basic mechanical components to today’s sophisticated electronic systems, the auto parts landscape has dramatically changed, reflecting advancements in technology and shifts in consumer expectations.

- E-commerce Growth Online shopping for auto spare parts is gaining popularity, making it easier for consumers to compare prices and find the parts they need without visiting multiple physical stores.

2. Preventing Engine Damage One of the most significant risks of a failing timing belt is the potential for catastrophic engine damage. If the timing belt breaks while the engine is running, it can cause the pistons to collide with the valves, leading to bent valves, damaged pistons, or even a complete engine failure. This type of damage can be extremely costly to repair and can be easily avoided with proper maintenance.

The designation 535-5M-15 provides essential information regarding the characteristics of the belt. The first part, 535, refers to the length of the belt in millimeters, indicating that this belt measures 535 mm in circumference. The 5M denotes the pitch of the teeth on the belt, which is 5 millimeters, and the 15 signifies the number of teeth. Understanding these specifications is crucial for selecting the correct timing belt that will fit a specific e-scooter model.

Understanding the New Serpentine Belt An Essential Component for Modern Vehicles

The serpentine belt is designed to wrap around several pulleys in the engine, creating a continuous loop. Its primary objective is to transfer power from the engine’s crankshaft to the various accessories that require it. This is achieved through the rotation of the crankshaft which, in turn, spins the serpentine belt. The belt's ability to power multiple components simultaneously allows for a more compact engine design, reducing the number of belts required compared to older vehicles that often had multiple V-belts.

Drive belt suppliers play a vital role in various industries by providing essential components that ensure the smooth functioning of machinery and vehicles. Understanding the types of belts available, as well as the critical factors in selecting a supplier, can lead to more informed decisions. By partnering with reliable suppliers, businesses can enhance their operational efficiency, reduce maintenance costs, and ensure that their equipment performs optimally.

Moreover, the COVID-19 pandemic highlighted the vulnerabilities of global supply chains, leading to a resurgence of interest in domestic manufacturing. As businesses reevaluate their supply chain strategies, there is an increasing push to bring production back to the United States. This trend has been referred to as reshoring, and it presents a significant opportunity for the manufacturing belt to reclaim its status as a vital player in the global economy.

1. Rubber Belts These are the most common type found in cruiser motorcycles and scooters. They offer a quieter and smoother ride compared to chain drives. The rubber belts are flexible and can withstand significant stretching, making them ideal for various riding conditions.

Applications in Modern Vehicles

Applications of the 7PK Belt

Understanding the Importance of a Serpentine Belt

Beyond automotive applications, the 6PK belt also finds a place in numerous industrial settings. Machinery used in manufacturing, agricultural equipment, and other mechanical systems utilize these belts to transfer power efficiently. In conveyor systems, for instance, 6PK belts play a pivotal role in maintaining the movement of goods by connecting motors to pulleys.

4. Round Belts These are more flexible than flat belts and are ideal for smaller, lighter applications, such as in small machinery or conveyor systems.

drive belt suppliers

1. Cost-Effective By reducing wear and tear and minimizing maintenance efforts, these belts can lead to significant cost savings for businesses in the long run.

The Significance of Oil vs. Belt Understanding Their Roles in Mechanical Systems

1. Brand As with many automotive parts, brand reputation plays a significant role in pricing. Well-known brands tend to charge more due to their reliability and quality assurance. For instance, brands like Gates, Dayco, and Continental will often be priced higher than generic options due to their commitment to research and development, which ensures that their belts meet or exceed performance standards.

Regular maintenance is crucial to ensuring the longevity and performance of motorbike belts. Here are some tips on how to maintain them

Key Players in V-Belt Manufacturing

2. Check Tension Ensure that the belt is properly tensioned. Both over-tightening and under-tightening can lead to premature wear. Follow manufacturer guidelines for the appropriate tension settings.

Fazit

Understanding Tooth Belt Drives A Comprehensive Overview

2. Disconnect the Battery For safety reasons, disconnect the negative terminal of the battery to prevent any electrical shorts.

The Versatile Role of V-Belt Rough Tops in Modern Machinery