Links:

-

The hexagonal head design offers more than just convenience. It ensures a secure grip, preventing slippage during installation, and allows for precise torque application, reducing the risk of over-tightening or damage to the material. The hex head also enables the use of power tools, making installation faster and more efficient.

The Evolution of the Double End Stud and Its Role in Modern Engineering

One of the key advantages of using double-ended bolts with nuts in the middle is their versatility. Because of their design, these bolts can be used in a wide range of applications where a secure and adjustable connection is required. For example, they are commonly used in the assembly of structural steel frames, machinery, and other heavy-duty equipment. Fixing Resin Anchors A Comprehensive Guide

3. Application Consider the type of project you are working on. For furniture that will bear weight, such as shelves or cabinets, opt for screws or dowels that provide a strong and durable connection.

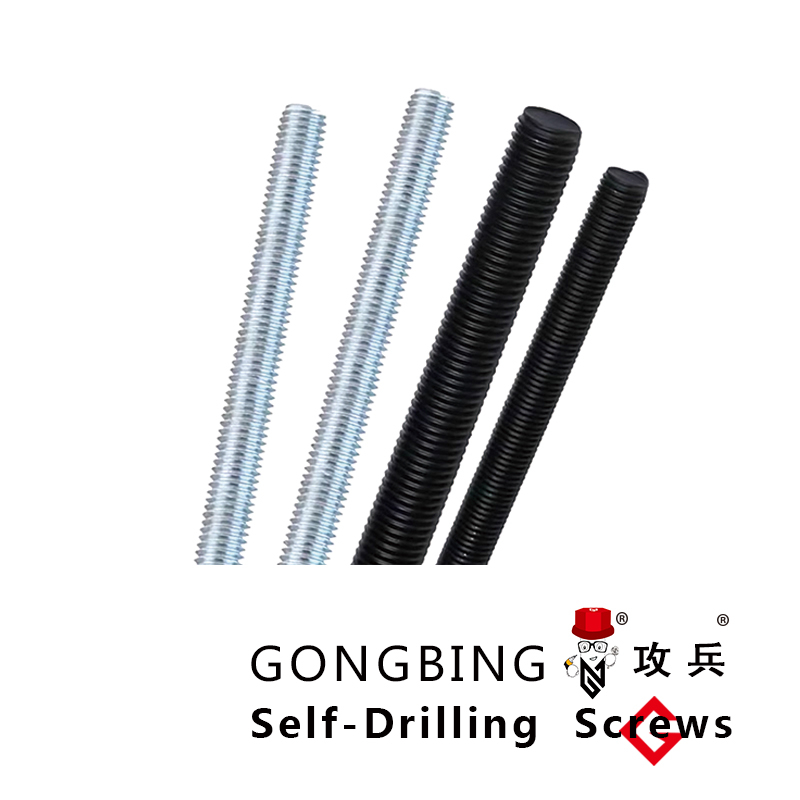

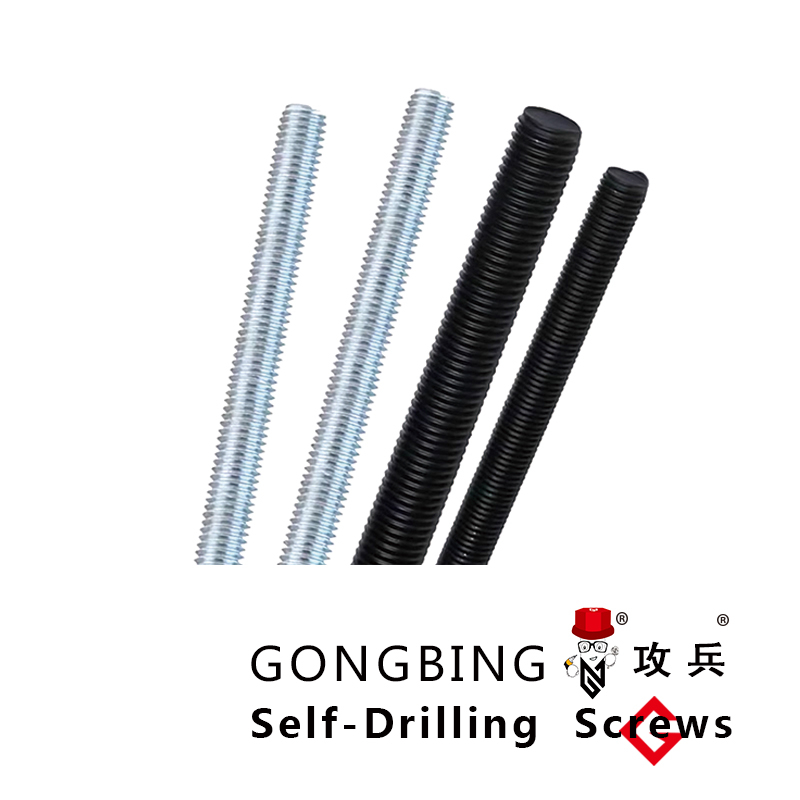

In conclusion, fully threaded bars represent a significant advancement in the field of construction. Their ability to enhance efficiency, improve quality, and provide excellent corrosion resistance make them an ideal choice for a wide range of construction applications. As the construction industry continues to evolve, it is likely that fully threaded bars will play an increasingly important role in shaping the future of building design and construction. Installing Butterfly Anchors A Comprehensive Guide Additionally, hex timber screws are known for their durability and resistance to wear and tear. Made from high-quality materials such as stainless steel or coated carbon steel, these screws are designed to withstand the elements and the stresses of everyday use. Whether you are building a deck, framing a house, or constructing furniture, hex timber screws are sure to provide long-lasting performance. In terms of application, self-drilling screws shine in areas where speed and strength are paramount. They are commonly used in building furniture, decking, fencing, and other outdoor structures where exposure to the elements demands robust joinery. Additionally, their usage extends to interior applications such as cabinetry and shelving units, where their concealed fixings maintain a polished finish.

3. Material and Coating Made typically from high-strength steel, 60mm Tek screws are often coated with corrosion-resistant materials, such as zinc or epoxy, to enhance durability and longevity, especially in outdoor environments or areas exposed to moisture.

One of the key advantages of continuously threaded rods is their ease of installation and maintenance. They can be easily tightened or loosened using nuts, allowing for adjustments or repairs without dismantling the entire structure. This feature significantly reduces downtime and labor costs, thereby increasing efficiency and cost-effectiveness.

Metric wedge anchors are essential components in construction and engineering projects, providing secure and reliable support for heavy loads. These anchors are designed to be used in solid concrete, providing a strong and durable connection for various applications.

When it comes to installation, using butterfly screws for TV mounts is a straightforward process. Simply mark the desired location on the wall, insert the screws, and tighten them by hand until they are securely in place. Once the screws are tightened, you can easily attach the TV mount and hang your television with confidence. Another benefit of the M6 Tek screw is its resistance to corrosion. Made from high-quality steel materials, this fastener is designed to withstand exposure to harsh environments and outdoor elements without rusting or deteriorating. This makes it an ideal choice for outdoor projects or applications where moisture and humidity are present. One of the significant advantages of nylon head self-drilling screws is their ability to resist corrosion, making them suitable for outdoor applications or environments with high moisture content. Their durability and resistance to wear also ensure a long lifespan, reducing the need for frequent replacements. When using stainless steel allen head wood screws, it is important to take proper precautions to ensure a secure and durable connection. Make sure to pre-drill pilot holes in the wood to prevent splitting and ensure a straight insertion. Use the correct size allen wrench or hex key to drive the screw in, being careful not to over-tighten or strip the screw.

2. Strength and Stability The design of countersunk screws allows for a greater surface area contact with the material, leading to a more secure fixation. This increases the overall strength and stability of the assembled components.

One of the most notable features of Wing Tek screws is their versatility. They can be found in a myriad of applications across different sectors, including construction, automotive, furniture manufacturing, and electronics.

Moreover, expansion anchor plastics are lightweight and easy to handle, simplifying the installation process. Their non-magnetic property also makes them suitable for use in environments where metal objects could interfere with electrical or magnetic fields. Additionally, their plastic composition allows for some flexibility, accommodating slight variations in hole size and surface irregularities. Moreover, nuts and bolts offer an advantage over (welding) due to their removable nature. This allows for easy assembly and disassembly, facilitating maintenance and repairs. They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors

They also allow for adjustments during construction, accommodating any unforeseen changes or errors They also allow for adjustments during construction, accommodating any unforeseen changes or errors construction nuts and bolts.

construction nuts and bolts. In terms of materials, hex head drilling screws are often made from high-strength steel, stainless steel, or a combination of both

. High-strength steel screws are ideal for heavy-duty applications, providing exceptional resistance to shear and tensile forces. On the other hand, stainless steel screws offer excellent corrosion resistance, making them suitable for outdoor projects or environments prone to moisture. The choice of material ultimately depends on the specific requirements of the project at hand.hex head drilling screw

In summary, the introduction of DIN6914/A325/A490 heavy-duty hexagonal structural bolts provides the construction industry with a new level of quality and performance. Its robust design, high-strength properties and compliance with industry standards make it the perfect fastening solution for structural steel applications. Whether you are a contractor, engineer or construction professional, this bolt is sure to meet and exceed your expectations for a heavy-duty hex structural bolt.

The process begins with drilling a hole in the drywall to accommodate the bolt's anchor. The butterfly bolt consists of two main parts the bolt itself and the spring-loaded wings. When inserted into the pre-drilled hole, the wings collapse, allowing the bolt to pass through the drywall. Once the bolt is pushed through and the nut is tightened from the front side, the wings expand against the inner surface of the drywall, creating a secure anchor point. This design ensures that the bolt not only holds the weight of the mounted object but also withstands any pull-out forces.Expanding wall anchors are specialized fasteners designed to provide a secure point for attaching items to walls, especially where there may not be a stud available for traditional nailing or screwing methods. These anchors work by expanding against the sides of the wall material as they are tightened, creating a holding force that distributes the weight of the object being hung.

Looking ahead, the future of self-drilling screws is promising, with ongoing advancements in material technology and manufacturing processes. As the industry continues to evolve, self-drilling screws are likely to become even more versatile, durable, and accessible to a wider range of applications. Their impact on construction and engineering will only continue to grow, driving innovation and progress in the industry.

Weld shear connector studs play a crucial role in the construction industry, particularly in the field of structural steel connections. These studs are used to transfer loads between the concrete slab and the steel beams or girders, providing a strong and reliable connection that is essential for the stability and integrity of a structure.In summary, stainless steel foundation bolts are essential elements in modern construction and engineering, providing security and stability while offering significant benefits over traditional materials. Their corrosion resistance, strength, durability, and aesthetic appeal make them the preferred choice for a wide range of applications. As the construction industry continues to evolve, the importance of high-quality, reliable materials like stainless steel will only increase, ensuring that structures not only stand the test of time but also meet the rigorous demands of safety and performance. Choosing stainless steel foundation bolts is an investment in the future, safeguarding the resilience and integrity of our built environment.

When it comes to construction and woodworking, choosing the right fasteners is paramount to ensuring the integrity and durability of the project. Among the various types of screws available, fine thread drywall screws have gained popularity due to their unique design and advantages, particularly when it comes to fastening materials to wood.

The Role of Chemical Anchor Fasteners in Modern Construction

3. Material M20 foundation bolts are often made from carbon steel or stainless steel. Carbon steel bolts are typically treated with galvanization or other finishes to improve corrosion resistance. Stainless steel bolts, while more expensive, offer superior corrosion resistance, making them suitable for harsh environmental conditions.

Washer head machine screws are employed in numerous applications across various fields. In construction, they are commonly used to secure metal components, ensuring structural integrity. The increased surface area of the washer head minimizes the risk of damage to softer materials, making these screws ideal for fastening to wood or plastic surfaces without causing splitting or cracking.

washer head machine screws

In conclusion, while the 1 202 wedge anchor bolt may be a small component in the grand scheme of things, it plays a vital role in ensuring the safety and stability of structures. By understanding the importance of proper installation and maintenance, engineers and contractors can maximize the benefits of this versatile and reliable fastener. The Impact of Metric-Driven Approaches on Double-Ended Studies

Challenges and Considerations

The double end threaded stud with wrench flats represents a remarkable advance in fastening technology. With its unique design, versatility, and user-friendly features, it addresses the demands of modern industries, offering reliable solutions for complex assembly requirements. As industries continue to evolve, the importance of such adaptable and efficient fastening solutions will only grow, solidifying the position of the double end threaded stud with wrench flats as a cornerstone in fastening technology.

In conclusion, M16 chemical anchor bolts are an invaluable tool in modern construction and engineering. Their strength, reliability, and versatility make them ideal for various applications, from simple installations to complex structural requirements. As construction techniques evolve, the demand for robust anchoring solutions like the M16 chemical anchor bolt is likely to increase, solidifying their place as a cornerstone in the engineering toolkit. When planning your next construction project, considering the deployment of M16 chemical anchor bolts could enhance safety, efficiency, and structural integrity.

The A325 specification includes various criteria that these fasteners must meet, such as mechanical properties, dimensional tolerances, and testing procedures. One of the critical attributes of A325 bolts is their ability to withstand significant tension and shear forces, making them ideal for applications in bridges, buildings, and other infrastructure projects.

2. Concrete construction Metric screws can be used for anchoring rebar in concrete, ensuring the structural integrity of the building. One of the key considerations in the selection of aircraft structural fasteners is their compatibility with the materials they will be fastening together. For example, aluminum fasteners are often used in conjunction with aluminum components to prevent galvanic corrosion, while stainless steel fasteners are preferred for attaching steel parts due to their superior strength and resistance to rust.

In summary, bracing is a vital component of steel structures that enhances their stability, safety, and overall performance. As the demand for taller and more complex structures grows, so does the need for effective bracing solutions. Engineers and architects must continue to innovate in their approaches to bracing, balancing aesthetic considerations with structural requirements. Through careful planning and implementation of bracing systems, steel structures can withstand the forces they encounter, ensuring longevity and safety for generations to come.

3. Metal fabrication They can be used for attaching metal components in industrial and commercial construction projects.

In conclusion, bolt structure is a critical element in engineering design, encompassing material selection, mechanical properties, surface treatment, and assembly techniques. A well-designed bolt can significantly enhance the reliability and durability of various structures and machinery. As engineers continue to innovate and refine bolt designs, the importance of understanding and applying the principles of bolt structure will remain a fundamental aspect of successful engineering practice. Whether in construction, manufacturing, or maintenance, bolts play an irreplaceable role in ensuring safety and functionality in countless applications around the globe.

One of the key benefits of self-drilling nails is their versatility. They can be used in a wide range of applications, including drywall installation, metal framing, and decking. The sharp tip of the nail is able to cut through the material as it is being driven in, creating a clean and precise hole that eliminates the risk of splitting or cracking. Another notable feature of Tek screws is their versatility

14g tek screws. They can be used in a variety of settings, from heavy-duty industrial applications to delicate woodworking projects. Their ability to perform well in different environments and under various loads makes them a versatile solution for a broad spectrum of needs.

14g tek screws. They can be used in a variety of settings, from heavy-duty industrial applications to delicate woodworking projects. Their ability to perform well in different environments and under various loads makes them a versatile solution for a broad spectrum of needs. Tek screws, also known as self-drilling screws, are a type of fastener commonly used in construction and manufacturing. With their unique design, tek screws are able to drill their own holes and secure materials without the need for pre-drilling.

In the vast world of engineering and construction, there are countless components that work together to create a sturdy and reliable structure. One such component is the 1 202 wedge anchor bolt, which may seem insignificant at first glance but plays a crucial role in ensuring the safety and stability of various structures. 2. Thread Type Butterfly screws also offer versatility in terms of material selection Overall, M4 hex head bolts are versatile and reliable fasteners that play a crucial role in various industries. Their strong and secure connection capabilities make them a popular choice for a wide range of applications. Whether used in construction, manufacturing, or automotive, M4 hex head bolts provide the durability and performance needed to achieve successful results. In the vast world of engineering and construction, there are countless components that work together to create a sturdy and reliable structure. One such component is the 1 202 wedge anchor bolt, which may seem insignificant at first glance but plays a crucial role in ensuring the safety and stability of various structures.