Links:

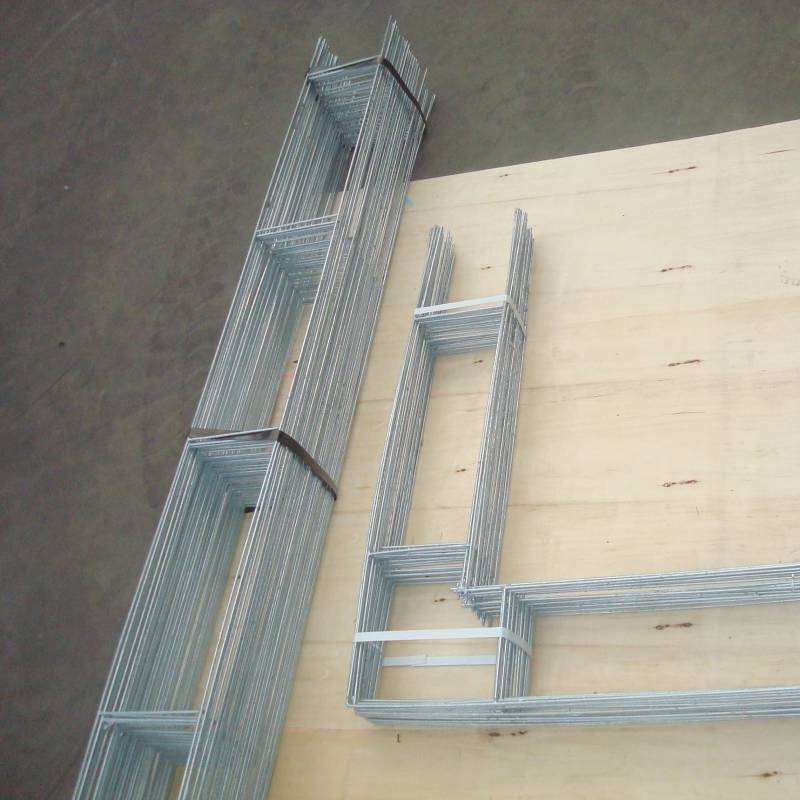

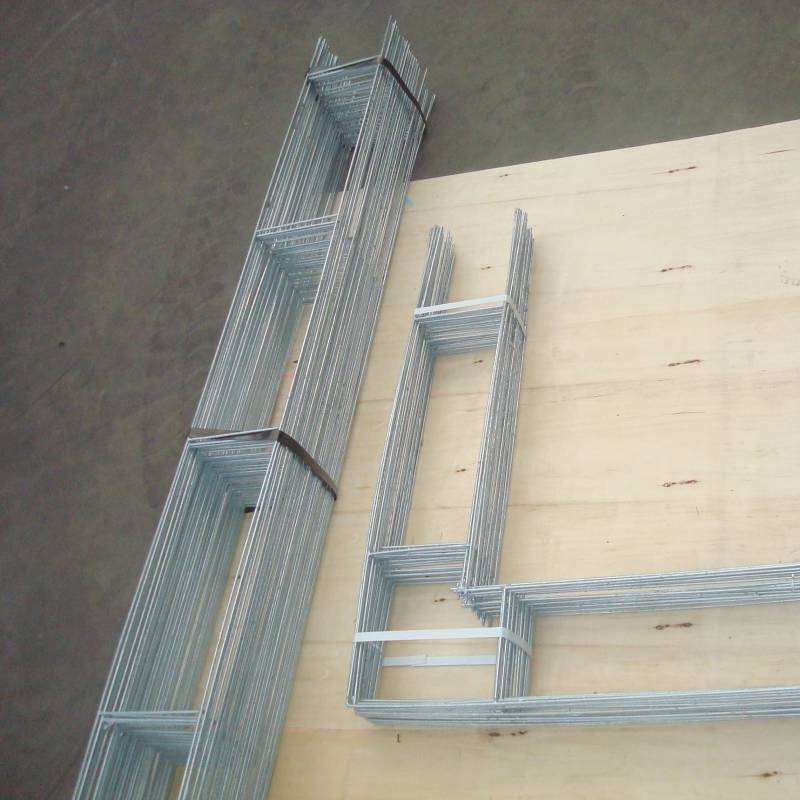

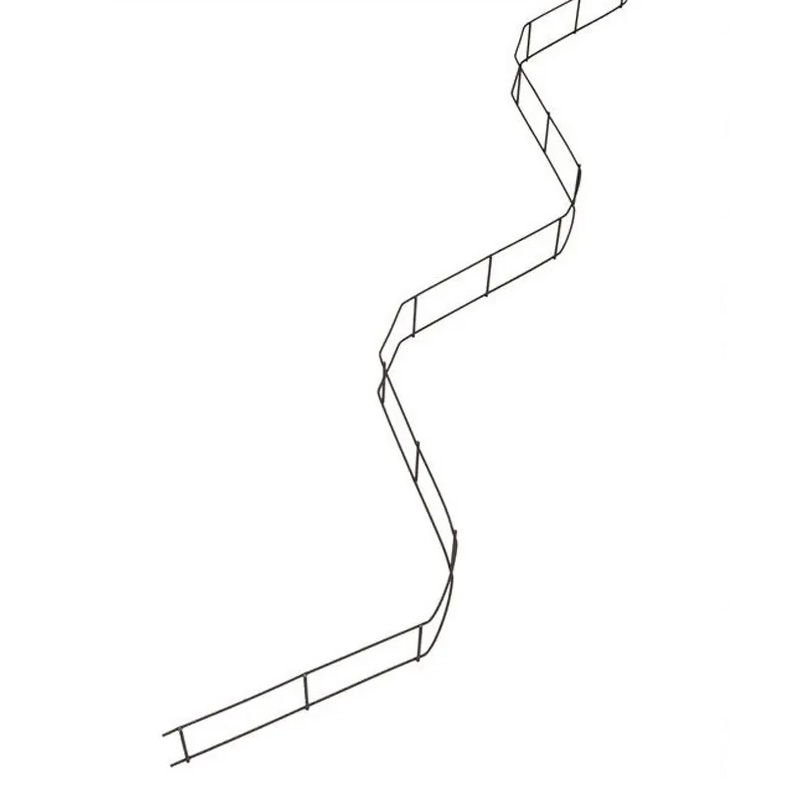

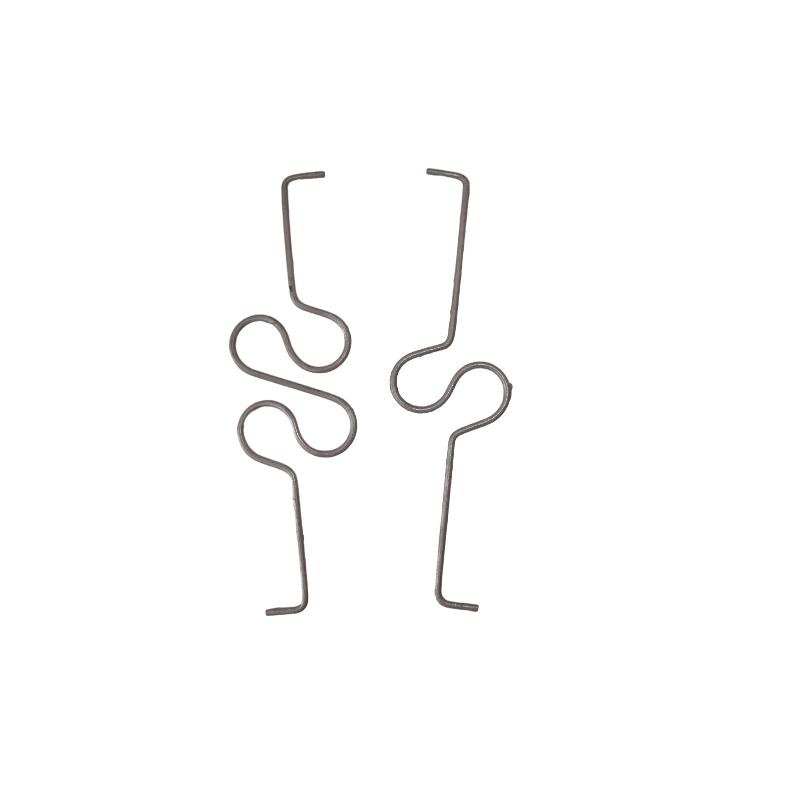

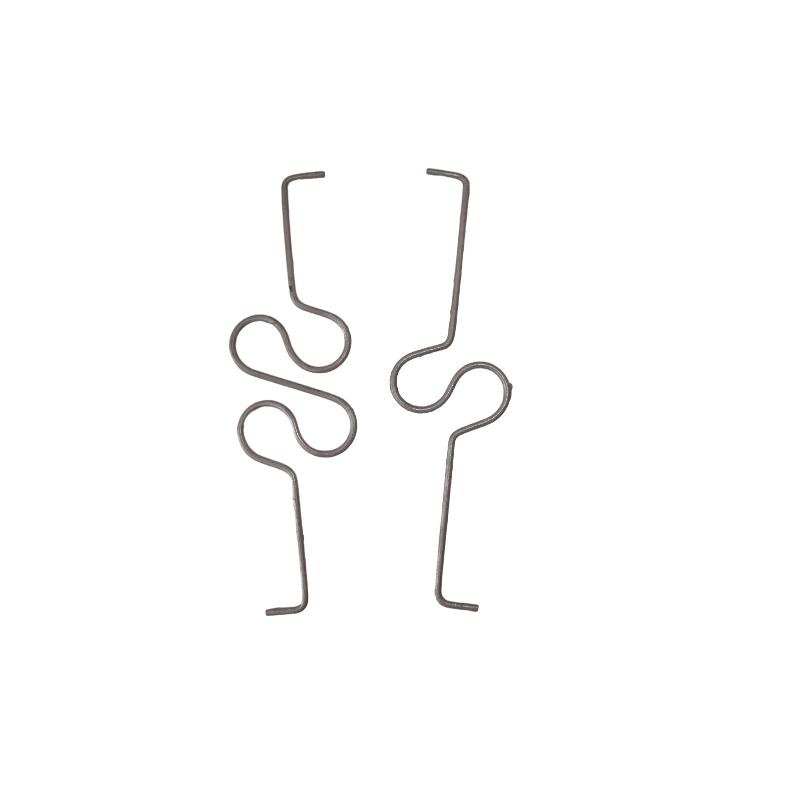

Cavity wall ties

The length and width of the roll also contribute to the overall cost. Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices

Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices Standard rolls are usually 50 feet or 100 feet long and 50 inches wide, but custom sizes are available at varying prices chicken wire price. Larger rolls generally offer a more cost-effective option per square foot.

chicken wire price. Larger rolls generally offer a more cost-effective option per square foot. Regardless of the type of wall tie used, it is important that they are installed correctly to ensure the structural integrity of the wall. Improper installation of wall ties can lead to cracking, sagging, or even collapse of the wall. It is recommended that wall ties are installed by a qualified professional to ensure that they are placed at the correct spacing and depth.

We sincerely invite customers from all over the world to come to our booth for business negotiations.

These two exhibitions are prestigious events in the hardware and building materials industry, attracting professionals, buyers, and industry leaders from around the globe. By participating in these exhibitions, we aim to showcase our latest products, technologies, and innovative solutions, and establish business partnerships with customers from different countries.

At our booth, you will have the opportunity to see a wide range of high-quality iron wire, wire mesh, concrete and masonry accessories, as well as deeply processed steel wire products. Our team of experts will be on hand to provide detailed information and answer any questions you may have.

Enhance the integrity of the wall: the various parts of the cavity wall can be effectively connected together by binding, so that they can work together under the action of earthquakes, reducing the cracking and scattering of the wall.

In conclusion, the construction of a butterfly tie is a labor of love, a testament to the craftsmanship and dedication of those who create them. Each tie tells a story, not just through its design but also through the careful hands that brought it to life. Whether worn at formal events or as a touch of flair in everyday attire, a butterfly tie carries with it the essence of tradition, artistry, and a touch of personal style. It's more than just a fashion accessory; it's a wearable piece of art, a symbol of refined taste, and a celebration of skilled craftsmanship. Several factors can influence the quality of annealed wire, including In addition to these benefits, stakes and supports also facilitate easier maintenance. Pruning, watering, and pest control become more manageable when plants are held off the ground or trained along a support. It also makes harvesting easier, especially for fruits and vegetables that grow high up. Design and Construction In conclusion, understanding the price of chicken wire involves considering the quality of materials, gauge and mesh size, dimensions, market conditions, and additional costs. It's essential to strike a balance between quality and affordability to ensure your investment serves its intended purpose effectively. Always shop around, compare prices, and consider your specific requirements before making a purchase. Remember, while cost is a significant factor, durability and functionality should not be compromised for a lower price tag. Plaster beading, a traditional craft that has been practiced for centuries, is enjoying a resurgence in popularity. This delicate and intricate art form involves creating intricate designs using small pieces of plaster or gypsum, which are then attached to a surface to create a decorative effect. Welded mesh sheets also exhibit excellent corrosion resistance when galvanized or coated, extending their lifespan in outdoor or corrosive environments. This adaptability, coupled with their inherent strength, makes them a go-to material in numerous sectors.Black chain mesh fencing is also highly customizable. With options for different gauges of wire, heights, and coatings, property owners can choose the specifications that best suit their needs. Additionally, black chain link fencing can be easily accessorized with privacy slats, barbed wire, or gates to further enhance its security and functionality.

2. Auto parts stores Local auto parts stores often carry a variety of coil springs for sale, including those designed for specific makes and models of cars and trucks. You can visit your local store or search online to find the right coil springs for your vehicle. White is the color of purity and simplicity. It is a neutral color that can be combined with other colors to create a harmonious palette. In interior design, white walls provide a clean canvas for decoration, allowing the focus to be on the furniture and artwork rather than the wall color. The versatility of coated floral wire is what sets it apart. It can be easily bent, twisted, or shaped into virtually any form, allowing artists and florists to bring their imaginative visions to life. From creating lifelike stems and branches to forming intricate wirework for flower crowns and boutonnieres, this wire is a true workhorse in the world of floral design. 5-inch coil springs are,、。,,。,,。,。 The manufacturing process of bulk compression springs involves precision winding of the wire, followed by heat treatment to enhance the spring's strength and durability. Quality control measures are rigorously implemented to ensure each spring meets the required specifications, ensuring consistent performance and longevity. Another benefit of stainless steel garden wire is its versatility. It can be used in a variety of ways to meet the needs of different gardening projects. For example, you can use it to create trellises for climbing plants, support structures for vines, or even as a border around flower beds. The wire can also be cut and shaped to fit any size or shape of garden, making it a highly adaptable material. The Art of Masonry Ties A Blend of Past and Present In the realm of signage, metal stakes play a pivotal role in ensuring that messages are conveyed effectively and efficiently. These sturdy, durable fixtures serve as the backbone of outdoor signs, providing both stability and visibility to a wide range of informational, promotional, and directional signage. Whether it's a road sign directing traffic, a promotional banner advertising an event, or a property marker indicating boundaries, metal stakes are indispensable tools in our daily lives. The Ubiquitous Role of Tension Coil Springs in Modern Technology Understanding Brick Tie Spacing Requirements A Key to Structural Integrity

In manufacturing and fabrication processes, galvanized iron wire is used in a multitude of applications, from assembling machinery and equipment to fabricating industrial components. The wire's versatility allows it to be formed into custom shapes and configurations to meet specific manufacturing requirements. Whether used as reinforcement in composite materials, support for ductwork and piping systems, or as a fastening component in assembly lines, galvanized iron wire provides a cost-effective and reliable solution for a wide range of industrial needs. Its resistance to corrosion ensures that manufactured products maintain their integrity and functionality, even in demanding industrial environments.

Ultimately, the possibilities for using red craft wire are limited only by the artist's imagination. Whether it's used in jewelry making, sculpture, floral arrangements, or any other form of art, red craft wire adds a vibrant and dynamic element to any project. Its bold color and flexible nature make it a favorite medium among artists of all skill levels, and its versatility ensures that there is always something new and exciting to create with red craft wire. Moreover, the cavity also provides a space for additional insulation materials, such as mineral wool or polystyrene beads, to be installed, further enhancing the wall's thermal performance Imagine walking down the busy streets of Manhattan, where every corner is filled with the cacophony of life, and suddenly catching sight of a double-sided sign holder. One side might carry a message of hope and inspiration, reminding passersby of the beauty that lies within the daily grind. The other side could bear a call to action, urging people to consider the needs of their community or to reflect on global issues.

Imagine walking down the busy streets of Manhattan, where every corner is filled with the cacophony of life, and suddenly catching sight of a double-sided sign holder. One side might carry a message of hope and inspiration, reminding passersby of the beauty that lies within the daily grind. The other side could bear a call to action, urging people to consider the needs of their community or to reflect on global issues. In addition to businesses, small sign stakes are also commonly used by organizations and individuals for various purposes

. For example, small sign stakes can be used at events such as weddings, graduations, or parties to direct guests to different areas or provide information about the event. They can also be used in residential areas to indicate property boundaries, display house numbers, or promote neighborhood events.small sign stakes

The choice of material for flat wire springs depends on the specific requirements of the application. Some of the most commonly used materials include

Wire Mesh Use

Another advantage of PVC galvanized wire is its cost-effectiveness. Despite its superior performance and durability, PVC galvanized wire is an affordable option compared to other types of wire. Its long lifespan and low maintenance requirements make it a cost-effective solution for various projects, saving both time and money in the long run. The selection of the right type of 250mm brick tie depends on several factors, including the cavity width, the load-bearing capacity required, and the environmental conditions In conclusion, chain link security fences are a practical, cost-effective, and versatile option for protecting property and securing boundaries. Their strength, durability, visibility, and customization options make them a popular choice for many property owners. Whether used in commercial, industrial, or residential settings, chain link security fences provide peace of mind and reliable security for property owners. Another factor that can affect the lifespan of wall ties is the environment they are exposed to. Wall ties that are installed in coastal areas or regions with high levels of air pollution may deteriorate more quickly due to exposure to salt, moisture, and pollutants. In these cases, regular maintenance and inspections are essential to ensure the wall ties are still providing adequate support to the masonry walls. 5-inch coil springs are,、。,,。,,。,。 One way to save money on welded steel mesh is to purchase it in bulk In addition to its functional advantages, wall reinforcement mesh contributes to sustainable construction. The use of steel, a highly recyclable material, aligns with the growing emphasis on eco-friendly building practices. Moreover, the enhanced durability of reinforced structures often translates to a longer lifespan, reducing the need for frequent repairs or replacements.Wire mesh is a versatile material with a wide range of applications in a variety of industries and environments. From industrial to residential uses, wire mesh is a popular choice because of its durability, strength, and flexibility. One of the most common types of wire mesh is black stainless steel wire mesh, which is known for its corrosion resistance and smooth appearance.

The choice of reinforcement material largely depends on the type of masonry and the specific requirements of the project. Steel, for instance, is a popular choice due to its high tensile strength and compatibility with masonry materials. It can be placed in the horizontal beds (bedding joints) or vertical joints (perp joints) to provide lateral stability and resist shear forces. The primary function of mesh reinforcement in concrete slabs is to control cracking and reduce the risk of structural failure. Concrete tends to crack due to a variety of factors, including shrinkage, temperature changes, and external loads. By adding mesh reinforcement, the tensile strength of the concrete is increased, allowing it to better resist cracking and maintain its structural integrity over time. Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points

Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points Additionally, mesh reinforcement helps distribute loads more evenly throughout the slab, reducing the risk of localized stress and potential failure points mesh for concrete slab. In recent years, there has been a shift towards more modern, engineered brick ties that offer improved performance and longevity. These advanced ties incorporate features like expansion mechanisms, which allow for some movement due to temperature changes or building settlement, without compromising the structural integrity. Innovations in masonry veneer anchor technology have led to more efficient and safer solutions. For example, the development of anchoring systems with built-in movement capabilities allows for some degree of structural movement without compromising the integrity of the veneer. This is particularly beneficial in regions prone to earthquakes or temperature-induced expansion and contraction.

mesh for concrete slab. In recent years, there has been a shift towards more modern, engineered brick ties that offer improved performance and longevity. These advanced ties incorporate features like expansion mechanisms, which allow for some movement due to temperature changes or building settlement, without compromising the structural integrity. Innovations in masonry veneer anchor technology have led to more efficient and safer solutions. For example, the development of anchoring systems with built-in movement capabilities allows for some degree of structural movement without compromising the integrity of the veneer. This is particularly beneficial in regions prone to earthquakes or temperature-induced expansion and contraction. One of the key benefits of heavy duty tension springs is their ability to provide consistent and reliable force over a long period of time

. These springs are designed to resist fatigue and deformation, even when subjected to extreme conditions or heavy loads. This reliability is essential in critical applications where failure could have serious consequences.Measuring Torsion Spring When it comes to appearance, Type 2 wall ties add a touch of sophistication to any space. Their clean lines and subtle sheen blend seamlessly with the surrounding decor, enhancing the overall aesthetic of the room. Whether you choose to highlight them with a contrasting color or let them blend into the background, these ties will undoubtedly make a statement without being overbearing. Wholesale chicken wire fencing is a cost-effective and versatile solution for securing and containing poultry and other animals on a farm or in a backyard. This type of fencing is made from galvanized steel wire that is woven into a hexagonal mesh pattern, creating a strong and durable barrier that can withstand the elements and potential damage from animals. Aluminum chain link fences are also very affordable compared to other types of fencing materials. The cost of aluminum is typically lower than materials such as wrought iron or steel, making it a cost-effective choice for property owners on a budget. Additionally, the installation process for aluminum chain link fences is relatively simple and straightforward, further reducing the overall cost of the project. One of the most common applications of spring steel coil is in the manufacturing of springs. Springs are essential components in many mechanical devices and systems, such as automotive suspensions, industrial machinery, and household appliances. Spring steel coils are used to create these springs because of their ability to return to their original shape after being bent or compressed. This property allows springs to absorb and release energy efficiently, making them ideal for applications where repetitive motion is required. When it comes to maintenance, galvanized tomato cages require very little effort. Unlike wooden or plastic cages, they do not need to be painted or treated to prevent rot or decay. Simply give them a quick rinse after each use to remove any dirt or debris, and they will remain in excellent condition for years to come. 1. Electronics Annealed wire is commonly used in the production of electronic components such as resistors, capacitors, and inductors.