Links:

-

The catalogue doesn't end there; it extends to the customization options. Whether it's a custom size, shape, or finish, the catalogue details how manufacturers can cater to bespoke requirements. It also provides information on additional services such as cutting, welding, and coating. In addition to its versatility, handcrafted wire jewelry also offers a sense of satisfaction and accomplishment to those who create it. The process of shaping, twisting, and weaving wire into beautiful and intricate designs requires patience, precision, and skill. As makers hone their craft and experiment with new techniques, they develop their own unique style and artistic vision, resulting in pieces that are not only visually appealing but also imbued with a sense of creativity and artistry. In conclusion, aluminum wire floral design is more than just a craft; it is a symphony of artistry and innovation. It combines the timeless appeal of flowers with the durability of metal, resulting in works of art that resonate with both traditional and contemporary aesthetics. As this art form continues to evolve, it invites us to appreciate the beauty that lies at the intersection of nature and human ingenuity. Cavity walls, a popular choice in modern construction, consist of two parallel walls separated by a gap or 'cavity.' This design offers improved insulation, moisture resistance, and fire protection. However, without effective wall ties, the two walls would function independently, potentially leading to structural failure over time. In addition to its durability and flexibility, thick craft wire is also available in a wide range of colors and finishes

Small extension springs, on the other hand, are ideal for applications where space is limited. Despite their larger size, they still provide reliable extension and retraction functions, making them suitable for use in electronics, medical equipment, and precision instruments.

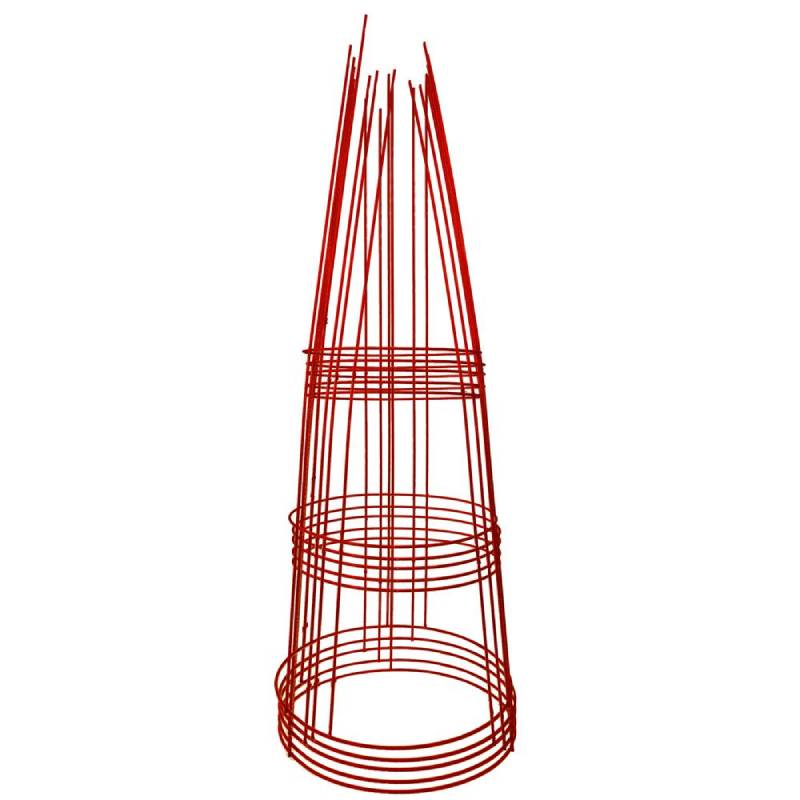

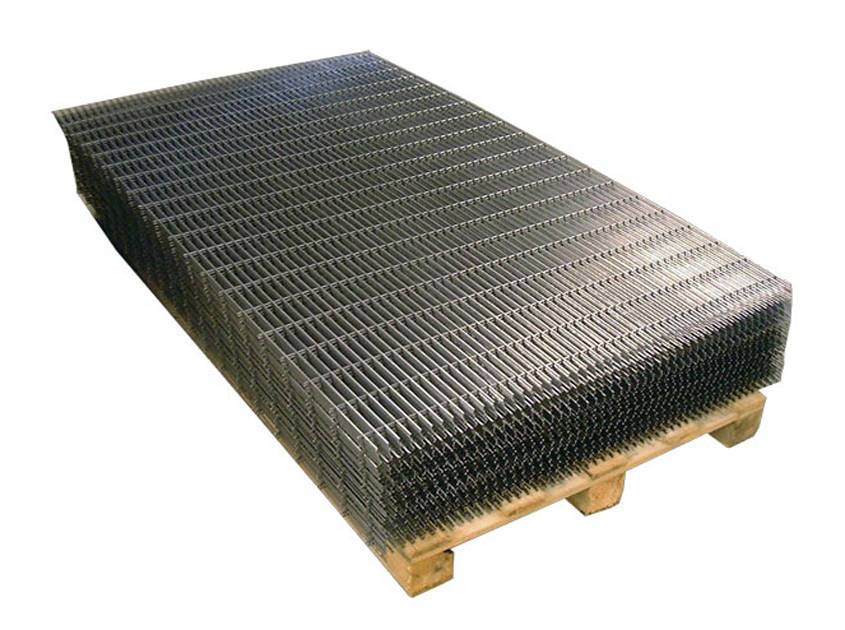

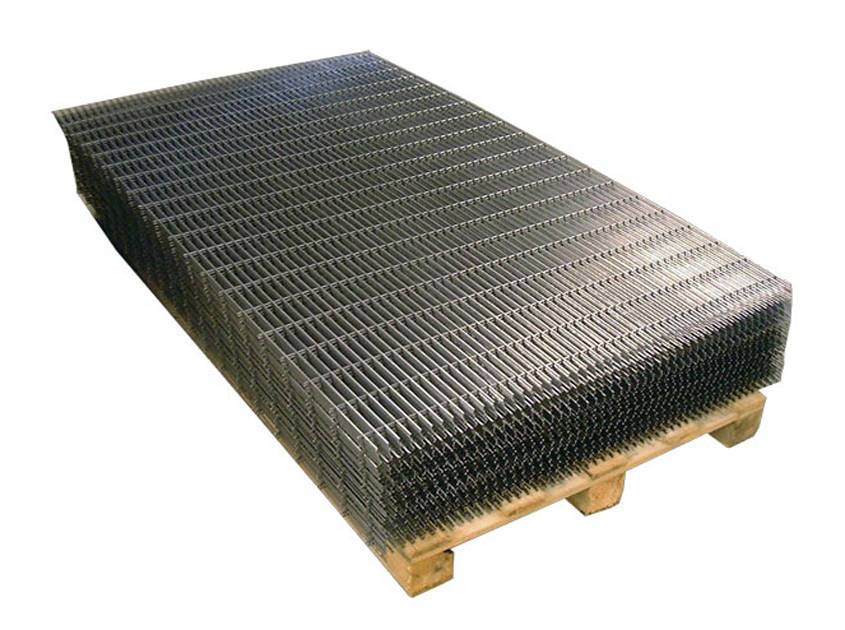

1. Material selection The first step is to select the appropriate material based on the specific requirements of the application. Moreover, Type 2 wall ties are highly resistant to environmental factors such as moisture and extreme temperatures In the realm of architecture and construction, the humble brick has long been a staple. Its durability, versatility, and aesthetic appeal have made it an essential element in the creation of structures that stand the test of time. However, beyond its functional role, bricks also possess a unique characteristic that sets them apart their ability to create strong, lasting connections. Welded wire reinforcement for concrete is a crucial component in building strong and durable structures. This type of reinforcement is made by welding together individual steel wires to form a grid or mesh pattern. The grid is then placed within the concrete to provide additional strength and support. One of the primary uses of galvanized steel wire lies in the construction industry. It is commonly used in reinforcing concrete, providing additional strength and stability to structures. Additionally, it forms the backbone of many scaffolding systems, ensuring worker safety during construction projects. Its robustness also makes it ideal for creating wire mesh for fencing and roofing, offering a secure and long-lasting solution. The Artistic Versatility of Pink Craft Wire A Creative Journey In addition to being stylish, stubby ties are also practical. They are easy to tie and adjust, making them perfect for busy professionals who don't have time to fuss with complicated knots. And because they sit closer to the neck than regular ties, they are less likely to get caught on things or become undone throughout the day. Furthermore, in daily life, GI Iron wire is found in the manufacture of household items such as brooms, baskets, and even furniture. Its durability and affordability make it a popular choice for manufacturers. Another advantage of using a tomato cage is that it can help to space out the branches of the plant, allowing for better light penetration and air circulation

In the realm of architecture and construction, the humble brick has long been a staple. Its durability, versatility, and aesthetic appeal have made it an essential element in the creation of structures that stand the test of time. However, beyond its functional role, bricks also possess a unique characteristic that sets them apart their ability to create strong, lasting connections. Welded wire reinforcement for concrete is a crucial component in building strong and durable structures. This type of reinforcement is made by welding together individual steel wires to form a grid or mesh pattern. The grid is then placed within the concrete to provide additional strength and support. One of the primary uses of galvanized steel wire lies in the construction industry. It is commonly used in reinforcing concrete, providing additional strength and stability to structures. Additionally, it forms the backbone of many scaffolding systems, ensuring worker safety during construction projects. Its robustness also makes it ideal for creating wire mesh for fencing and roofing, offering a secure and long-lasting solution. The Artistic Versatility of Pink Craft Wire A Creative Journey In addition to being stylish, stubby ties are also practical. They are easy to tie and adjust, making them perfect for busy professionals who don't have time to fuss with complicated knots. And because they sit closer to the neck than regular ties, they are less likely to get caught on things or become undone throughout the day. Furthermore, in daily life, GI Iron wire is found in the manufacture of household items such as brooms, baskets, and even furniture. Its durability and affordability make it a popular choice for manufacturers. Another advantage of using a tomato cage is that it can help to space out the branches of the plant, allowing for better light penetration and air circulation

52 tomato cage. When tomato plants are too crowded, they can become prone to fungal diseases and other issues that can affect their growth and productivity. By using a tomato cage to support the plant and keep it upright, you can ensure that each branch has enough space to grow and thrive. Wall ties are essential components in masonry construction, playing a crucial role in maintaining the structural integrity of cavity walls. They connect the inner and outer leaves of the wall, providing stability and preventing lateral movement. Installing wall ties is a critical process that requires precision and understanding. This article will delve into the intricacies of installing wall ties, emphasizing safety measures, necessary tools, and step-by-step procedures.

Extension springs are important components in various mechanical systems, providing the force needed to extend and retract parts. They come in a variety of types and designs, including Extension springs with loop ends, extension springs with hook ends, and custom extension springs. These springs are designed to absorb and store energy, releasing it when the spring is extended or pulled.

One of the key advantages of using weldmesh in construction is its ability to distribute weight evenly across a surface. This helps to prevent cracks and fractures in concrete structures, ensuring their longevity and durability. Additionally, weldmesh is highly resistant to corrosion and rust, making it ideal for outdoor applications where exposure to the elements is a concern. In conclusion, the brick tie detail, though often unseen, is a vital aspect of architectural design and construction. It symbolizes the intricate balance between form and function, aesthetics and engineering, history and innovation. As we marvel at the grandeur of buildings, let us not forget the silent heroes like brick ties that silently hold them together, making our homes and cities safer and more resilient. The type of construction also influences the spacing of brick veneer ties. In buildings with a lightweight structure, such as wood frame construction, the ties may need to be spaced closer together to ensure that the brick veneer is properly supported. In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties

In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties In contrast, buildings with a more robust structural frame, such as concrete or steel, may allow for wider spacing of the ties brick veneer tie spacing. In modern construction, corrugated metal wall ties have evolved alongside advancements in engineering and technology. Today, they come in various sizes and types, catering to specific project requirements and architectural designs. From traditional applications in cavity walls to their usage in contemporary green buildings, corrugated metal wall ties continue to be a fundamental element in construction. Cavity wall ties are an essential component of any building with cavity walls. These ties are used to connect the inner and outer walls, providing stability and preventing the walls from separating or collapsing. However, over time, cavity wall ties can fail, leading to serious structural issues that require costly repairs. Moreover, Type 2 wall ties are highly resistant to environmental factors such as moisture and extreme temperatures

brick veneer tie spacing. In modern construction, corrugated metal wall ties have evolved alongside advancements in engineering and technology. Today, they come in various sizes and types, catering to specific project requirements and architectural designs. From traditional applications in cavity walls to their usage in contemporary green buildings, corrugated metal wall ties continue to be a fundamental element in construction. Cavity wall ties are an essential component of any building with cavity walls. These ties are used to connect the inner and outer walls, providing stability and preventing the walls from separating or collapsing. However, over time, cavity wall ties can fail, leading to serious structural issues that require costly repairs. Moreover, Type 2 wall ties are highly resistant to environmental factors such as moisture and extreme temperatures Furthermore, these fences come in a wide range of designs and sizes, from the traditional square or rectangular patterns to more intricate hexagonal or diagonal meshes. This variety ensures that there's a wire mesh garden fence to complement every garden's unique character and design. In addition to its durability and flexibility, thick craft wire is also available in a wide range of colors and finishes

Furthermore, these fences come in a wide range of designs and sizes, from the traditional square or rectangular patterns to more intricate hexagonal or diagonal meshes. This variety ensures that there's a wire mesh garden fence to complement every garden's unique character and design. In addition to its durability and flexibility, thick craft wire is also available in a wide range of colors and finishes Tension coil springs, an integral part of the vast machinery and engineering world, play a pivotal role in various industries ranging from automotive to aerospace, from consumer electronics to heavy machinery. These compact, helical structures, wound under tension, embody the essence of resilience and strength, converting stored energy into dynamic force. 6. Surface treatment The springs are treated to improve their corrosion resistance and durability. This may involve coating the springs with a protective layer or plating them with a metal such as nickel or chrome. Moreover, these panels offer excellent ventilation and light diffusion, making them perfect for use in environments where air circulation and natural light are crucial. In commercial buildings, they can enhance energy efficiency by facilitating the flow of air conditioning and lighting systems. They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

Tension coil springs, an integral part of the vast machinery and engineering world, play a pivotal role in various industries ranging from automotive to aerospace, from consumer electronics to heavy machinery. These compact, helical structures, wound under tension, embody the essence of resilience and strength, converting stored energy into dynamic force. 6. Surface treatment The springs are treated to improve their corrosion resistance and durability. This may involve coating the springs with a protective layer or plating them with a metal such as nickel or chrome. Moreover, these panels offer excellent ventilation and light diffusion, making them perfect for use in environments where air circulation and natural light are crucial. In commercial buildings, they can enhance energy efficiency by facilitating the flow of air conditioning and lighting systems. They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management

They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management They also allow for easy installation and maintenance of electrical conduits and plumbing lines, simplifying building management square metal grid panel. while (buffer.getData() != null && !coder.isKeyFrame()) { In the vast expanse of the world, there exists a simple yet profound creation that has stood the test of time the wire link fence. This versatile structure, often overlooked, serves multiple purposes and adds an aesthetic touch to any landscape.

square metal grid panel. while (buffer.getData() != null && !coder.isKeyFrame()) { In the vast expanse of the world, there exists a simple yet profound creation that has stood the test of time the wire link fence. This versatile structure, often overlooked, serves multiple purposes and adds an aesthetic touch to any landscape. Horizontal joint reinforcement, masonry joint reinforcement, and brick reinforcement ladders are essential techniques for ensuring the structural integrity and durability of masonry constructions. These reinforcement methods play a critical role in preventing cracks, distributing loads evenly, and enhancing the overall stability of masonry walls. By incorporating these techniques into their projects, builders can create safer, more resilient structures that stand the test of time. Understanding and utilizing these reinforcement strategies is crucial for achieving high-quality masonry construction.

Supporting Plant Growth with Black Annealed Wire

Understanding the importance of h stakeholders requires acknowledging the broader concept of corporate social responsibility (CSR). Companies no longer operate solely for profit; they must consider the interests and well-being of all stakeholders. By doing so, they foster trust, enhance reputation, and ultimately drive long-term sustainability. Galvanized Mesh Fencing A Durable and Practical Barrier Solution The humble chicken netting fence, a structure often underestimated, stands as a testament to the ingenuity and practicality that agricultural advancements have bestowed upon modern poultry husbandry. This unassuming barrier is not merely a partition; it embodies the principles of safety, efficiency, and sustainability that are paramount in today’s farming practices.8 gauge galvanized wire

Affordable Tomato Cages The Economical Solution for Robust Garden Growth Green wire mesh fencing is also a cost-effective option for property owners looking to secure their space without breaking the bank. Its long-lasting durability ensures that it will stand the test of time, requiring minimal maintenance and upkeep

green wire mesh fencing. This makes it a cost-effective investment in the long run, saving property owners both time and money. The spacing requirements for brick ties vary depending on the specific type of brick being used and the local building codes

brick tie spacing requirements. However, there are some general guidelines that can be followed to ensure proper installation. For example, tie wires should be spaced approximately every 16 inches (40 cm) along the length of the wall, while metal clips or bar ties may be spaced every 8 to 12 inches (20 to 30 cm). It is also important to ensure that the ties are installed at the correct depth within the mortar joint, usually about 1/2 to 3/4 inch (1.3 to 1.9 cm) from the face of the brick. Amaryllis plant stakes are an essential gardening tool that provide support and stability to these beautiful and popular flowers. These stakes are designed to be used with amaryllis plants, which are known for their large, showy blooms that add a touch of elegance to any garden or home. As the name suggests, adjustable compression springs are springs that can be adjusted to vary their level of compression. These springs are designed with a unique mechanism that allows users to change the spring's length or tension by either adding or removing coils. This feature makes them highly adaptable and suitable for a wide range of applications where the spring's force needs to be precisely controlled. When discussing the 1 8 extension spring, it's essential to consider factors like fatigue life, which refers to the number of cycles the spring can endure before losing its original properties. High-quality extension springs are designed to withstand numerous cycles without significant deformation or failure. Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. This makes galvanized steel much more resistant to rust and weathering than untreated steel. As a result, galvanized tomato cages can withstand the harsh conditions of outdoor environments, including extreme temperatures, rain, and wind. Secondly, the 200mm cavity serves as an effective drainage channel. It allows any water that manages to penetrate the outer leaf of the wall to drain out through weep holes, preventing saturation and potential damage to the inner leaf. This is especially crucial in areas with high rainfall or humidity, ensuring the longevity and structural integrity of the building. Once the baskets were ready, the artists climbed the tree and attached them to the branches. It was a meticulous process, requiring patience and skill. But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes

brick tie spacing requirements. However, there are some general guidelines that can be followed to ensure proper installation. For example, tie wires should be spaced approximately every 16 inches (40 cm) along the length of the wall, while metal clips or bar ties may be spaced every 8 to 12 inches (20 to 30 cm). It is also important to ensure that the ties are installed at the correct depth within the mortar joint, usually about 1/2 to 3/4 inch (1.3 to 1.9 cm) from the face of the brick. Amaryllis plant stakes are an essential gardening tool that provide support and stability to these beautiful and popular flowers. These stakes are designed to be used with amaryllis plants, which are known for their large, showy blooms that add a touch of elegance to any garden or home. As the name suggests, adjustable compression springs are springs that can be adjusted to vary their level of compression. These springs are designed with a unique mechanism that allows users to change the spring's length or tension by either adding or removing coils. This feature makes them highly adaptable and suitable for a wide range of applications where the spring's force needs to be precisely controlled. When discussing the 1 8 extension spring, it's essential to consider factors like fatigue life, which refers to the number of cycles the spring can endure before losing its original properties. High-quality extension springs are designed to withstand numerous cycles without significant deformation or failure. Galvanization is a process that involves coating steel with a layer of zinc to protect it from corrosion. This makes galvanized steel much more resistant to rust and weathering than untreated steel. As a result, galvanized tomato cages can withstand the harsh conditions of outdoor environments, including extreme temperatures, rain, and wind. Secondly, the 200mm cavity serves as an effective drainage channel. It allows any water that manages to penetrate the outer leaf of the wall to drain out through weep holes, preventing saturation and potential damage to the inner leaf. This is especially crucial in areas with high rainfall or humidity, ensuring the longevity and structural integrity of the building. Once the baskets were ready, the artists climbed the tree and attached them to the branches. It was a meticulous process, requiring patience and skill. But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes

But as they worked, the tree began to take on a new life, transforming into something magical before their eyes But as they worked, the tree began to take on a new life, transforming into something magical before their eyes metal basket tree. One of the main benefits of using welded wire reinforcement for concrete is its ability to distribute loads evenly throughout the structure. This helps prevent cracks and other forms of damage that can occur due to stress and strain. The grid pattern allows for greater flexibility and movement within the concrete, which can help absorb shocks and vibrations.

metal basket tree. One of the main benefits of using welded wire reinforcement for concrete is its ability to distribute loads evenly throughout the structure. This helps prevent cracks and other forms of damage that can occur due to stress and strain. The grid pattern allows for greater flexibility and movement within the concrete, which can help absorb shocks and vibrations. Black annealed wire is an essential material in the construction industry, primarily used for tying rebar (reinforcing bars) to ensure the stability and consistency of structures. This process is critical in creating reinforced concrete, which is a fundamental component of modern construction. The wire’s flexibility allows it to be easily wrapped around rebar, holding it securely in place. This not only ensures that the rebar remains in the correct position during the pouring and curing of concrete but also helps in maintaining the overall integrity of the structure.

Innovations in materials science have also influenced the development of heavy duty brick ties In the water treatment industry, 1 inch wire mesh is used to filter impurities from water 1 inch wire mesh. Its porous structure allows water to pass through while retaining solids, making it an effective method for removing sediment, debris, and other contaminants. This makes 1 inch wire mesh an essential component in water treatment plants and systems. One of the key benefits of using welded reinforcing mesh is its ability to evenly distribute the load across a surface. This helps to prevent cracking and damage to the concrete, especially in areas where stress and pressure are concentrated. By reinforcing the concrete with mesh, builders can ensure that the structure remains intact and safe for years to come.

1 inch wire mesh. Its porous structure allows water to pass through while retaining solids, making it an effective method for removing sediment, debris, and other contaminants. This makes 1 inch wire mesh an essential component in water treatment plants and systems. One of the key benefits of using welded reinforcing mesh is its ability to evenly distribute the load across a surface. This helps to prevent cracking and damage to the concrete, especially in areas where stress and pressure are concentrated. By reinforcing the concrete with mesh, builders can ensure that the structure remains intact and safe for years to come.