Current location:

Links:

-

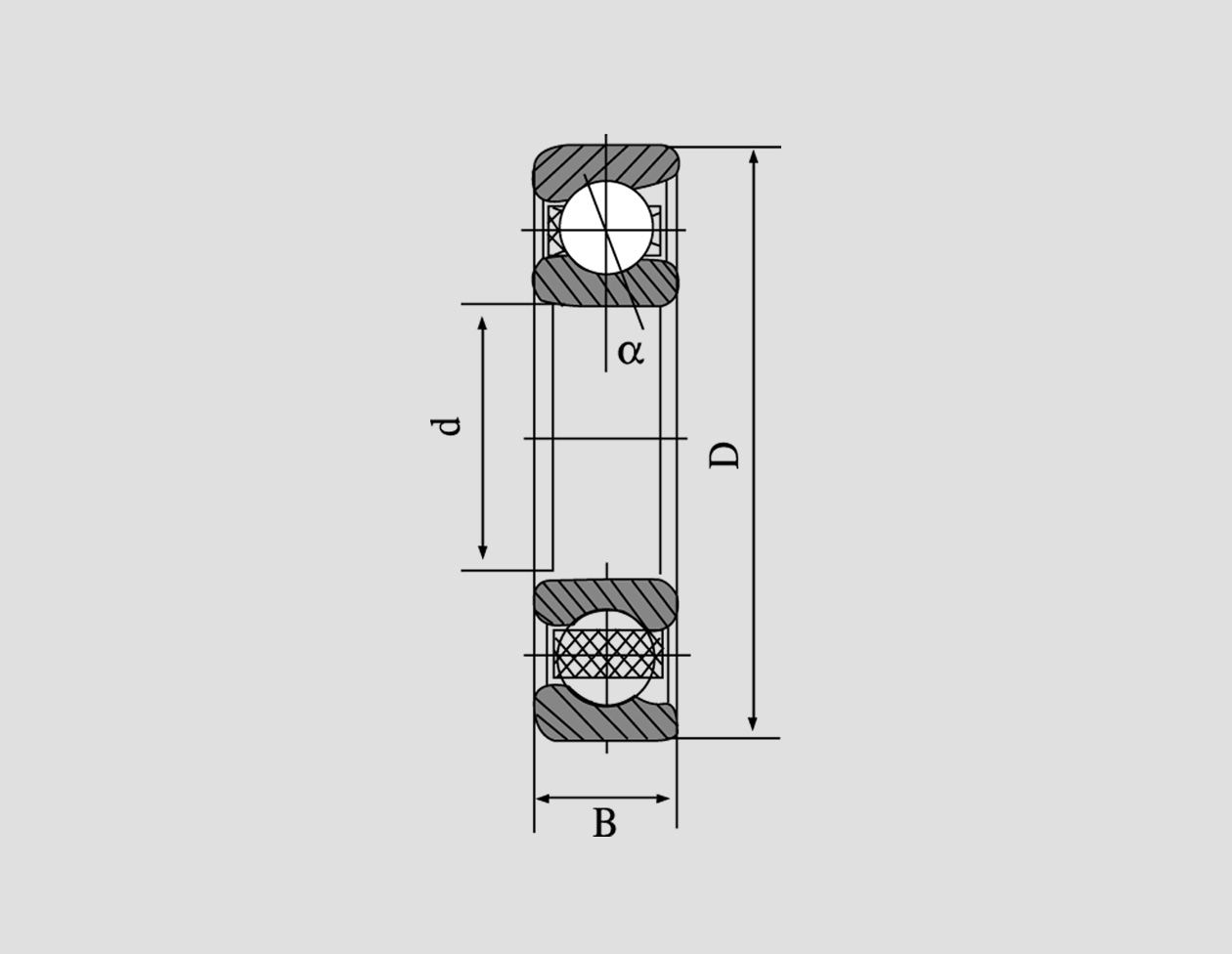

Both the LM11949 and LM11910 share a common thread of reliability and robustness At its core, a wheel bearing supports the weight of the vehicle, enabling smooth rotation between the hub and the wheel. It reduces friction, allowing the wheels to spin freely at high speeds with minimal energy loss. In the context of the L45449 Wheel Bearing, this function is amplified due to its reinforced construction, capable of handling substantial loads and harsh conditions. In addition to their high-speed capabilities, double angular contact bearings are also known for their high precision and stability. The contact angles of the two rows of balls are carefully engineered to provide optimal support and minimize deflection under heavy loads. This results in smoother operation, reduced vibration, and improved overall efficiency in the system.

- Machine Tools: Bearings are critical components in machine tools such as lathes, milling machines, and grinding machines, where precision motion and high rigidity are essential for machining operations.

The 31318 bearing is an essential component in many industrial machines and equipment. It is a type of roller bearing that is commonly used in a variety of applications, including automotive, agricultural machinery, construction equipment, and more. The 48548 bearing is made from high-quality materials, such as chrome steel, which ensures its durability and reliability. It features a unique design that allows for optimal load distribution, reducing friction and wear. The bearing also has a self-aligning feature, which helps to maintain proper alignment even under severe operating conditions. Understanding Bearing Dimensions for 61800 Series * Wind turbines Bearings 32010X play a crucial role in wind turbines by ensuring smooth rotation and maximizing energy production. The 51406 Bearing A Versatile Solution The material used to manufacture the 638 ZZ bearing is typically high-carbon chromium steel (AISI 52100), which offers excellent hardness, strength, and wear resistance. The balls are made from stainless steel or ceramic, providing superior corrosion resistance and dimensional stability. The cage is usually fabricated from polyamide or brass, which ensures efficient ball guidance and reduced noise levels. Benefits of Using the 23268 Bearing Furthermore, the 51317 bearing offers excellent corrosion resistance, which is essential in environments where machines are exposed to harsh chemicals or moisture

51317 bearing. The special coatings and materials used in their construction provide a protective barrier against corrosion, ensuring that the bearing maintains its integrity and performance even in the most challenging conditions. In the realm of heavy-duty industrial machinery, where massive loads and high speeds are the norm, traditional bearings simply cannot cut it. That's where four-row taper roller bearings come into play. These robust, high-performance bearings are specifically designed to handle the most demanding conditions, making them an indispensable asset in a wide range of industries.

51317 bearing. The special coatings and materials used in their construction provide a protective barrier against corrosion, ensuring that the bearing maintains its integrity and performance even in the most challenging conditions. In the realm of heavy-duty industrial machinery, where massive loads and high speeds are the norm, traditional bearings simply cannot cut it. That's where four-row taper roller bearings come into play. These robust, high-performance bearings are specifically designed to handle the most demanding conditions, making them an indispensable asset in a wide range of industries. In summary, the key differences between needle roller bearings and cylindrical roller bearings lie in their design, load-carrying capacity, and application suitability. Each type of bearing is tailored to meet specific operational requirements and environmental conditions in diverse industrial applications.

Widely recognized for their reliability and efficiency, deep groove ball bearings have found their way into countless applications, from household appliances like fans and washing machines to complex industrial machinery such as pumps, motors, and gearboxes. They are also prevalent in automotive engines, wheel hubs, and transmission systems. Introduction The Pivotal Role of Cylindrical Roller Bearing Manufacturers in Modern Industry Introduction To achieve such precision, SolidWorks offers advanced modeling techniques, including the use of sketch relations, dimension drives, and assembly constraints deep groove ball bearing solidworks. These tools allow engineers to define the geometric relationships between the bearing's components accurately, ensuring that the digital model behaves realistically under various operational conditions. One of the key differences between deep groove ball bearings and angular contact bearings is their load-carrying capacity and ability to accommodate various load types

deep groove ball bearing solidworks. These tools allow engineers to define the geometric relationships between the bearing's components accurately, ensuring that the digital model behaves realistically under various operational conditions. One of the key differences between deep groove ball bearings and angular contact bearings is their load-carrying capacity and ability to accommodate various load types

deep groove ball bearings or angular contact. Deep groove ball bearings are more suitable for applications with primarily radial loads, while angular contact bearings are better equipped to handle combined axial and radial loads. Additionally, angular contact bearings are designed to withstand higher speeds and provide improved precision compared to deep groove ball bearings. One of the key advantages of using a deep groove bearing puller is its ability to handle a wide range of bearing sizes and types. Whether you need to remove a small bearing or a large one, a quality puller will be able to get the job done efficiently. Additionally, these tools are relatively easy to use, even for those without extensive mechanical experience. Maintenance and proper installation of the 51110 thrust bearing are essential for optimal performance. Regular lubrication helps minimize wear and prolongs the life of the bearing. Moreover, correct alignment and preload can significantly enhance the load-bearing capacity and reduce vibrations.

2. Check the installation Ensure that the bearing is properly installed and that all parts are securely fastened. In conclusion, the double row thrust ball bearing is a testament to the marriage of precision engineering and practical functionality. Its robust design, high load-bearing capacity, and versatility make it a go-to solution for numerous industrial applications. As technology continues to evolve, so does the development of these bearings, promising even higher performance standards and reliability in the future. Whether it's a massive turbine or a compact automotive component, the double row thrust ball bearing remains an indomitable force, silently ensuring the smooth running of countless machines worldwide. Firstly, let's understand the functionality of deep groove ball bearings. They consist of an outer ring, inner ring, balls, and a cage, which hold the balls in place and maintain uniform spacing. The design allows for radial and some axial loads to be supported simultaneously, making them suitable for a wide range of applications, from automotive to industrial machinery. 3

double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited. Overall, Bearing 6304 C3 is a reliable and cost-effective solution for various industrial applications. Its high-quality construction, advanced design, and versatile performance make it a popular choice among manufacturers and equipment operators. With the ability to handle high speeds, heavy loads, and changing load directions, this bearing is a valuable component in ensuring smooth and efficient operation of machinery and equipment. When interpreting a thrust needle roller bearing size chart, it's essential to consider the specific application's requirements, including the magnitude and direction of the load, operating speeds, and environmental factors. Compatibility with the housing, as well as any additional components like seals or washers, should also be assessed. Whether you are in the mining, automotive, or aerospace industry, the Hyatt cylindrical roller bearing catalog has the right bearing solution for your needs. With a proven track record of quality and reliability, Hyatt bearings are trusted by engineers and manufacturers around the world to deliver superior performance and durability in their applications. Cylindrical Roller Bearings A Comprehensive Guide for Suppliers Spherical roller bearings are a type of rolling element bearing that is widely used in various industries due to its ability to accommodate misalignment and support heavy loads. One of the critical factors that determine the performance and longevity of these bearings is their radial clearance. In this article, we will delve into the concept of radial clearance, its importance, and how it is calculated and adjusted in spherical roller bearings. 6014 Bearing Dimensions A Comprehensive Guide Bearings are essential components in various machinery and equipment, providing support, reducing friction, and enabling smooth rotation. The 6309 bearing is a popular choice due to its robust design and performance capabilities. This article delves into the detailed 6309 bearing specification, including dimensions, material composition, load capacity, and other critical factors that determine its suitability for different applications. One of the most fascinating aspects of cryptography is its ability to evolve and adapt to new threats. As technology advances, so too do the methods used by attackers to compromise secure communications. This constant battle between cryptographers and hackers has led to the development of some of the most sophisticated encryption techniques known to man. In conclusion, the 61908 bearing is a testament to the power of engineering in solving complex mechanical challenges. Its combination of strength, efficiency, and versatility makes it a vital element in the machinery of today and tomorrow. As technology continues to evolve, so will the 61908 bearing, adapting to new demands and pushing the boundaries of what's possible in the realm of mechanical engineering. In conclusion, the 29338 bearing represents a major breakthrough in rotary motion technology. Its superior durability, versatility, and performance make it an essential component in numerous applications, from everyday devices to complex machinery. As we continue to push the boundaries of innovation and seek solutions to global challenges, the 29338 bearing stands as a testament to human ingenuity and our relentless pursuit of progress. Market demand is another key factor influencing bearing prices 5. Replace the bearing at the first sign of failure. Delaying replacement can lead to further damage and reduce the overall lifespan of the mechanical system. One of the most significant advantages of cylindrical roller bearings is their durability. They can operate under harsh conditions, including extreme temperatures and heavy vibration, without significant wear and tear. Additionally, they offer improved rigidity and resistance to misalignment due to their robust construction.

double row deep groove ball bearing size chart. Space constraints Consider the available space within your machinery to determine the appropriate bearing size. Smaller bearings may be more suitable if space is limited. Overall, Bearing 6304 C3 is a reliable and cost-effective solution for various industrial applications. Its high-quality construction, advanced design, and versatile performance make it a popular choice among manufacturers and equipment operators. With the ability to handle high speeds, heavy loads, and changing load directions, this bearing is a valuable component in ensuring smooth and efficient operation of machinery and equipment. When interpreting a thrust needle roller bearing size chart, it's essential to consider the specific application's requirements, including the magnitude and direction of the load, operating speeds, and environmental factors. Compatibility with the housing, as well as any additional components like seals or washers, should also be assessed. Whether you are in the mining, automotive, or aerospace industry, the Hyatt cylindrical roller bearing catalog has the right bearing solution for your needs. With a proven track record of quality and reliability, Hyatt bearings are trusted by engineers and manufacturers around the world to deliver superior performance and durability in their applications. Cylindrical Roller Bearings A Comprehensive Guide for Suppliers Spherical roller bearings are a type of rolling element bearing that is widely used in various industries due to its ability to accommodate misalignment and support heavy loads. One of the critical factors that determine the performance and longevity of these bearings is their radial clearance. In this article, we will delve into the concept of radial clearance, its importance, and how it is calculated and adjusted in spherical roller bearings. 6014 Bearing Dimensions A Comprehensive Guide Bearings are essential components in various machinery and equipment, providing support, reducing friction, and enabling smooth rotation. The 6309 bearing is a popular choice due to its robust design and performance capabilities. This article delves into the detailed 6309 bearing specification, including dimensions, material composition, load capacity, and other critical factors that determine its suitability for different applications. One of the most fascinating aspects of cryptography is its ability to evolve and adapt to new threats. As technology advances, so too do the methods used by attackers to compromise secure communications. This constant battle between cryptographers and hackers has led to the development of some of the most sophisticated encryption techniques known to man. In conclusion, the 61908 bearing is a testament to the power of engineering in solving complex mechanical challenges. Its combination of strength, efficiency, and versatility makes it a vital element in the machinery of today and tomorrow. As technology continues to evolve, so will the 61908 bearing, adapting to new demands and pushing the boundaries of what's possible in the realm of mechanical engineering. In conclusion, the 29338 bearing represents a major breakthrough in rotary motion technology. Its superior durability, versatility, and performance make it an essential component in numerous applications, from everyday devices to complex machinery. As we continue to push the boundaries of innovation and seek solutions to global challenges, the 29338 bearing stands as a testament to human ingenuity and our relentless pursuit of progress. Market demand is another key factor influencing bearing prices 5. Replace the bearing at the first sign of failure. Delaying replacement can lead to further damage and reduce the overall lifespan of the mechanical system. One of the most significant advantages of cylindrical roller bearings is their durability. They can operate under harsh conditions, including extreme temperatures and heavy vibration, without significant wear and tear. Additionally, they offer improved rigidity and resistance to misalignment due to their robust construction. 2. Aerospace Industry The high load capacity and precision design of the 6301 bearing make it suitable for use in aircraft engines, landing gear, and other critical components. Cylindrical roller bearings and spherical roller bearings are two types of rolling bearings that are widely used in various industries due to their excellent load-carrying capacity, high reliability, and long service life. The C3 part of the designation indicates the bearing's internal clearance. It denotes that the bearing has a larger clearance than the standard (C0) classification, allowing for greater thermal expansion and improved lubrication. This feature is particularly beneficial in applications where high-speed rotations or fluctuating loads are expected. Maintenance and Care * Improved efficiency The high load capacity and stiffness of the bearing allow for increased operational efficiency, reducing downtime and maintenance costs Bearing Type and Size