Links:

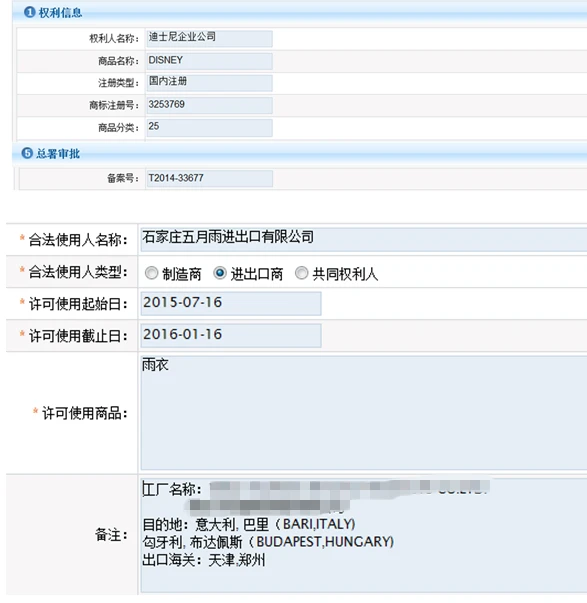

Water softener systems for houses are becoming increasingly popular as more people become aware of the benefits they can provide

. These systems are designed to remove minerals such as calcium and magnesium from hard water, which can cause a variety of issues in the home.1. Durability and Longevity One of the primary advantages of FRP louvers is their exceptional durability. Unlike metal, which can corrode when exposed to moisture and chemicals, FRP is resistant to rust and degradation. This characteristic ensures that FRP louvers maintain their structural integrity and performance over time, reducing the need for frequent replacements.

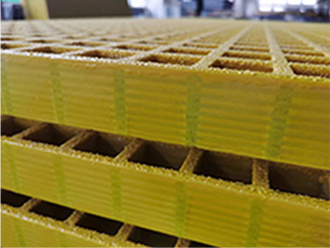

One of the standout features of fibreglass walkway grating is its exceptional strength-to-weight ratio. This quality enables easy handling and installation, reducing labor costs and time on site. Unlike heavy steel grates, fibreglass options can be transported and installed with minimal effort. The lightweight nature of the material also allows for designs that can support substantial loads while maintaining structural integrity, which is particularly crucial in high-traffic areas.

In today's world, the choice of fencing for residential and commercial properties is crucial. While traditional wood and metal fences have long been popular, Glass Reinforced Plastic (GRP) fence panels have emerged as a superior alternative. This innovative material offers a range of advantages that make it an ideal choice for various applications. In this article, we will explore the many benefits of GRP fence panels, highlighting their durability, aesthetic appeal, environmental impact, and maintenance ease.

5. Aesthetic Integration Modern urban planning increasingly emphasizes the aesthetic aspects of infrastructure. The square water tank with cage can be designed to blend into the landscape, featuring murals, greenery, or other artistic elements. This approach not only improves the visual appeal but also promotes community engagement and awareness regarding water conservation.

2. Lightweight and Easy to Install FRP grating is significantly lighter than its metal counterparts, which makes transportation and installation more straightforward. The reduced weight not only leads to lower transportation costs but also simplifies the labor required for installation. This efficiency can result in substantial time and cost savings for construction projects.

frp floor grating

The pricing of 1665 FRP vessels is also subject to fluctuations in market demand and broader economic factors. In recent years, the maritime industry has experienced shifts in demand due to changes in environmental regulations, industry practices, and the overall economic climate. Increased demand for vessels that resist corrosion and support sustainability initiatives has propelled FRP vessels into the spotlight. Consequently, when demand rises, so too does the pricing.

FRP Vessel with Multiport Valve A Comprehensive Overview

In the construction and design industry, safety and durability are paramount. When it comes to stairs, ensuring the utmost security while maintaining aesthetic appeal is essential. One effective solution that has emerged in recent years is the use of fiberglass stair treads. These innovative products are not only functional but also versatile in design, making them a preferred choice for various settings.

1. Material Composition Different types of fiberglass and resins can change the overall cost. For instance, premium resins designed for harsh chemical environments may drive up costs. In contrast, standard resins used in less demanding applications may be more economical.

Characteristics of CHS Steel Tubes

- Environment Evaluate the environmental conditions of the intended application. If exposure to chemicals or extreme weather is a concern, ensure that the chosen grating has the appropriate chemical resistance.

In today's world, safety in both residential and commercial spaces has never been more crucial. One area that often goes overlooked is the design and material choice of stair treads. This is where Fiber-Reinforced Polymer (FRP) stair treads come into play. These innovative treads offer a multitude of benefits, making them an excellent choice for various applications.

Additionally, non-slip metal grating is seen in outdoor environments, such as parks, playgrounds, and public transport stations, where they provide safe walking surfaces in high-traffic areas. Their resistance to corrosion and harsh weather conditions makes them an excellent choice for outdoor applications.

The pricing of any equipment, including the Pentair Vessel 1465, is influenced by several factors

- Public Infrastructure Municipalities are increasingly looking at FRP for public installations. Their lightweight nature eases the construction process, and their durability ensures longevity for public stairways in parks, public transport facilities, and more.

Key Components of the RO System

In agricultural settings, square poly tanks are essential for irrigation practices. Farmers can store large volumes of water, ensuring that crops receive consistent hydration even during dry spells. Similarly, in commercial and industrial sectors, these tanks serve as vital resources for process water, cooling, and fire protection systems.

Benefits of GRP Floor Grating

3. Non-Conductive Properties Unlike metal posts, fiberglass rods do not conduct electricity. This property is particularly important in electric fence systems. It helps to minimize the risk of accidental electric shocks during installation and maintenance while ensuring that the fence operates efficiently without energy loss through the support posts.

fiberglass rods for electric fence

In various industrial and commercial applications, the choice of materials is critical to ensure safety, efficiency, and durability. One such material that has gained popularity is Glass Reinforced Plastic (GRP) grating, particularly in a standard measurement of 38mm. GRP grating is a lightweight, high-strength product that offers numerous advantages over traditional materials like steel and wood. In this article, we will explore the features, applications, and benefits of 38mm GRP grating.

2. Low Maintenance Requirements Unlike wooden or painted handrails, which may require regular upkeep such as painting or varnishing, stainless steel handrails necessitate minimal maintenance. A simple periodic cleaning with soap and water is often sufficient to keep them looking new. This low maintenance requirement is not only cost-effective but also time-saving for property owners.

Routine inspections are essential to check the integrity of the tank, including the examination of welds, fittings, and the overall structure. Pressure relief valves should be tested regularly to ensure they are operational, as they act as a safeguard against over-pressurization.

Another significant benefit is its lightweight nature. FRP grating is substantially lighter than steel, which not only simplifies handling and installation but also reduces the overall structural load. This characteristic is particularly advantageous in applications where weight is a critical consideration, such as on elevated platforms or in marine environments.

Various methods are employed in industrial water treatment, each suited to specific water quality issues and end-use requirements. Here are some key techniques

Understanding FRP Technology

A whole house water filter and softener is a comprehensive solution for ensuring clean, safe, and luxurious water throughout your home. By investing in such a system, you not only enhance your family's health but also safeguard your plumbing and improve the longevity of your appliances. With clean water at your fingertips, you can enjoy the many benefits of a pure and soft water supply, making every sip and every shower a refreshing experience.

FRP railing systems are versatile and can be used in a wide range of applications. They are commonly used in

Versatile Applications

Heavy duty bar grating is an indispensable component in various industrial applications, renowned for its strength, durability, and versatility. This type of grating is typically composed of thick metal bars that are welded or press-locked together, creating an exceedingly robust framework capable of bearing heavy loads. Its applications range from flooring systems and walkways to platform supports and drainage covers, making it a critical element in sectors such as manufacturing, construction, and infrastructure.

Cost-Effectiveness

When shopping for a water softener, there are several options available

Exploring FRP Mesh Grating A Versatile Solution for Modern Applications

Fiberglass Water Tank A Modern Solution for Water Storage

In summary, 38mm GRP grating is a robust and reliable option for various industrial applications. Its lightweight nature, corrosion resistance, and safety features make it an excellent alternative to traditional materials. As industries continue to seek innovative solutions, GRP grating represents a significant advancement in terms of material technology, ensuring that functional and safety needs are met without compromising on performance. As with any material, it is crucial to assess the specific requirements of your project to determine the best fit, ensuring a successful installation that meets both performance and safety standards.

Molded FRP has found applications in a wide range of industries, including transportation, building and construction, and even consumer goods. In the transportation sector, molded FRP is used for manufacturing lightweight panels for vehicles, which can significantly improve fuel efficiency. In building and construction, it serves as an excellent choice for roofing, cladding, and structural components due to its resistance to corrosion and degradation. The waterproof nature of molded FRP also makes it an ideal material for components exposed to harsh environmental conditions, such as bridges and marinas.

What are GRP Sandwich Panels?

- Infrastructure Used extensively in highways and bridges, FRP guardrails effectively prevent vehicles from veering off course and protect pedestrians on walkways.

Fiberglass fence rods are constructed from a composite material made mainly of glass fibers and resin. This combination creates a product that is incredibly strong, yet lightweight compared to traditional materials like wood or metal. The manufacturing process involves weaving glass fibers into a mesh and then bonding them with a resin, resulting in a solid and flexible structure. This construction technique allows fiberglass rods to withstand significant tension and pressure, making them ideal for various fencing applications.

Conclusion

FRP Vessel with Multiport Valve A Comprehensive Overview

Additionally, CHS is increasingly utilized in the manufacturing of furniture and other consumer products, where both aesthetic and structural properties are essential. Designers often incorporate CHS into their designs for its sleek profile and modern appeal.

In conclusion, moulded grating represents a forward-thinking solution that meets the diverse demands of modern industries. Its strength, safety features, durability, and aesthetic versatility make it an excellent choice for various applications, from industrial settings to commercial and recreational areas. As industries continue to evolve and seek more efficient, safe, and environmentally friendly materials, moulded grating stands out as a reliable option that addresses these needs effectively. Its growing popularity is a testament to its benefits, and it is poised to remain a staple in flooring solutions for years to come.

Fiberglass stairs offer remarkable versatility in design. They can be molded into various shapes and sizes, allowing architects and designers to create unique and customized stair solutions to suit any project. Whether it's a minimalist design for a modern home or a grand staircase for a commercial building, fiberglass can deliver the desired aesthetic.

3. Oil and Gas Industry In the oil and gas sector, pressure tanks store hydrocarbons, ensuring that they are safely contained and transported. These tanks are designed to withstand harsh environmental conditions and extreme pressures.

1. Raw Material Costs The cost of fibers and resins used in the manufacturing of FRP plays a significant role. For instance, the price of carbon fiber can be substantially higher than that of glass fiber, directly impacting the overall pricing of the FRP products. Additionally, fluctuations in oil prices can affect the cost of polymer resins.

5. Versatility in Design FRP technology allows for flexibility in design. Vessels can be molded into various shapes and sizes to fit specific requirements. Customization options enable industries to create storage solutions that meet their precise operational needs.

Market demand is another critical factor affecting FRP rod prices. As the construction industry grows and the need for high-performance materials increases, the demand for FRP rods has surged. This increased demand can lead to higher prices, particularly if suppliers struggle to keep up. Conversely, if demand stabilizes or decreases, prices may fall as manufacturers seek to maintain market share.

What are Carbon Filter Vessels?

1. Material Composition GFRP bars are made from a combination of glass fibers and a polymer matrix. The type of glass fiber used (such as E-glass or S-glass) significantly affects the cost. Higher quality fibers may lead to increased prices but also offer superior strength and flexibility.