Links:

-

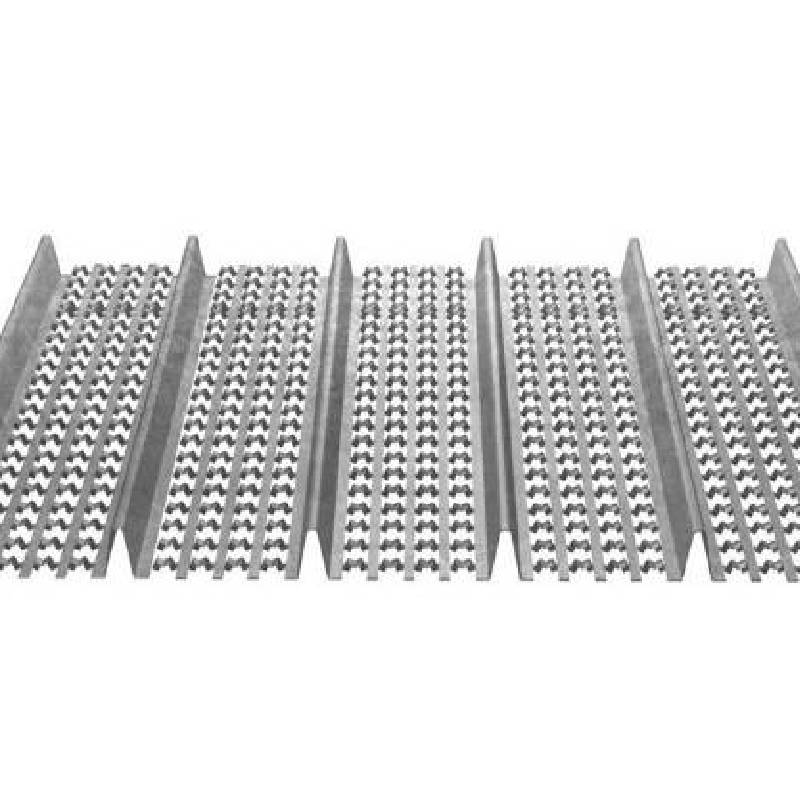

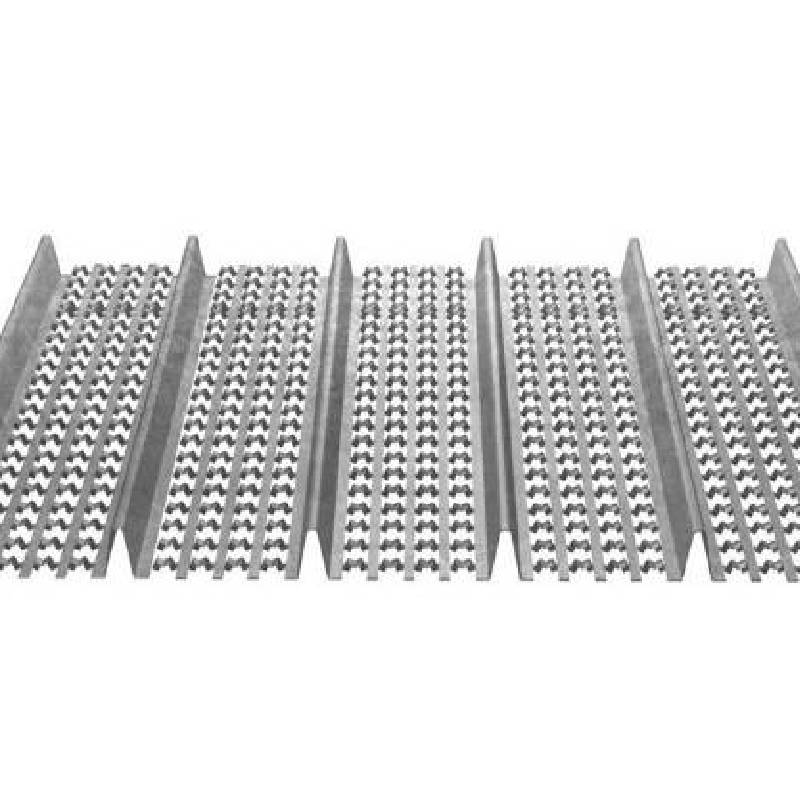

2. Acoustical Ceiling Panels Due to its light weight and good sound absorption properties, rib lath stainless steel is often used in the creation of acoustical ceiling panels. Furthermore, the installation process of metal stakes is straightforward and hassle-free. They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort

They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort

They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort They can be quickly and easily driven into the ground using manual or powered tools, reducing installation time and effort metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary. Galvanized Mesh Fencing A Durable and Practical Barrier Solution 2. Auto parts stores Local auto parts stores often carry a variety of coil springs for sale, including those designed for specific makes and models of cars and trucks. You can visit your local store or search online to find the right coil springs for your vehicle. In conclusion, 1.2mm garden wire is a versatile and essential tool for any gardener looking to create supports, barriers, or decorative elements in their outdoor space. Its thin but strong construction makes it ideal for a variety of tasks, and its ease of use makes it a valuable addition to any garden shed. Whether you are growing vegetables, flowers, or ornamental plants, garden wire can help you maintain a beautiful and well-organized garden all year round. In addition to its flexibility and versatility, a grid wall art display also offers a clean and modern aesthetic. The grid structure creates a neat and organized appearance, making it easy to create a well-balanced and visually appealing gallery wall. This streamlined look can complement a variety of decor styles, from minimalist and contemporary to bohemian and eclectic

metal stakes for signs. This efficiency is particularly valuable in scenarios where time is of the essence, such as during event setup or emergency situations where immediate signage is necessary. Galvanized Mesh Fencing A Durable and Practical Barrier Solution 2. Auto parts stores Local auto parts stores often carry a variety of coil springs for sale, including those designed for specific makes and models of cars and trucks. You can visit your local store or search online to find the right coil springs for your vehicle. In conclusion, 1.2mm garden wire is a versatile and essential tool for any gardener looking to create supports, barriers, or decorative elements in their outdoor space. Its thin but strong construction makes it ideal for a variety of tasks, and its ease of use makes it a valuable addition to any garden shed. Whether you are growing vegetables, flowers, or ornamental plants, garden wire can help you maintain a beautiful and well-organized garden all year round. In addition to its flexibility and versatility, a grid wall art display also offers a clean and modern aesthetic. The grid structure creates a neat and organized appearance, making it easy to create a well-balanced and visually appealing gallery wall. This streamlined look can complement a variety of decor styles, from minimalist and contemporary to bohemian and eclectic

grid wall art display. Overall, wholesale cattle fencing is a cost-effective and reliable solution for farmers looking to secure their livestock. With its affordability, ease of installation, and versatility, wholesale fencing offers a practical way to protect cattle while also staying within budget. By investing in high-quality fencing materials, farmers can ensure the safety and well-being of their livestock for years to come. Tomato cages provide structural support for the plant's stems and branches, preventing them from bending or breaking under the weight of the growing fruits. Without proper support, tomato plants can become overwhelmed and collapse, resulting in loss of fruit and potential damage to the plant itself. Tall plants, with their towering presence, provide a sense of grandeur and awe. They not only add vertical depth to the landscape but also serve as natural air purifiers by absorbing carbon dioxide and releasing oxygen. Moreover, their deep roots help prevent soil erosion and maintain soil fertility. In urban areas, tall plants serve as green barriers, reducing noise pollution and providing a peaceful respite from the hustle and bustle of city life. The Metal Basket Tree was the brainchild of a group of artists who sought to create something unique and memorable. They began by selecting a robust tree in a public park, one that could support the weight of their creation. The tree itself was majestic, its branches stretching out like open arms, ready to embrace whatever came its way. One of the key benefits of mini wire grid panels is their ability to save space while providing ample storage and display options. Because of their compact size, these panels can be easily set up in tight spaces or areas with limited floor space. This makes them ideal for businesses looking to maximize their display area without overcrowding their store.

In conclusion, iron and wire products, including iron binding wire, iron barbed wire, and various forms of annealed wire, are essential in multiple industries. Their versatility, strength, and durability ensure that they meet the diverse needs of construction, agriculture, and beyond. By understanding the specific properties and applications of these materials, businesses and individuals can choose the right type of wire for their particular requirements, ensuring efficiency and effectiveness in their projects.

When it comes to promoting your business or event, nothing catches the eye quite like a well-designed yard sign. However, in order to ensure that your sign stays upright and visible, you'll need the right stakes to support it. 6x30 yard sign stakes are the perfect solution for keeping your sign secure and in place.External corner plaster beads are an essential component in the construction and finishing of exterior corners in buildings. They provide a clean and professional look while also adding durability and protection to the corners of a structure. Properties of Rib Lath Stainless Steel One of the key benefits of using horizontal sign holders is their ability to attract attention and convey information in a concise and visually appealing way. These holders are typically made of clear acrylic or plastic material, allowing for the easy insertion of printed signs or posters. The horizontal orientation of the holder ensures that the information is easily readable from a distance, making it perfect for displaying important messages or promotions in high-traffic areas. 2. Telecommunications The excellent electrical conductivity of annealed wire makes it ideal for use in telecommunications cables and wires.

Annealed wire is wire that has been heat treated to make it more ductile and easier to work with. The process involves heating the wire to high temperatures and then cooling it slowly, which helps annealed wire remove internal stress and improves its ductility. The result is a softer, more pliable wire that's ideal for bending, twisting and shaping into different shapes.

One of the key advantages of wire shelving grids lies in their modularity. They can be easily assembled and disassembled, making them highly adaptable to changing storage needs. The grid pattern allows for custom configurations, with shelves adjustable in height to accommodate items of varying sizes. Moreover, additional accessories like drawers, hooks, and baskets can be attached to the grid system, enhancing its functionality. Furthermore, the wire is employed in the manufacturing of staple pins, nails, and other fasteners, where resistance to corrosion is paramount. In telecommunications, galvanizing wire is used in overhead ground wires, providing both conductivity and durability. A timber frame wall tie is essentially a metal strip or bar, usually made from stainless steel, zinc-plated steel, or other corrosion-resistant materials. Their primary function is to resist lateral forces and prevent the separation of the timber frame from the brick or blockwork, which could lead to serious structural issues if not properly installed. Butterfly ties are an innovative and efficient method used to secure cavity walls and provide additional structural support. These ties, also known as cavity wall ties, are typically used in construction to connect the internal and external walls of a building. The unique design of butterfly ties features a wider middle section with two thinner arms that extend outwards, resembling the wings of a butterfly. This design allows for increased strength and stability, making them ideal for securing cavity walls. Woven metal mesh is a versatile and durable material that has been used in a wide range of applications for centuries. The interlocking metal wires create a strong and flexible structure that can be used for various purposes, from architectural facades to industrial filtration systems. One way to save money on welded steel mesh is to purchase it in bulk welded steel mesh price. Many suppliers offer discounts for large orders, so buying more mesh at once can reduce the overall cost per unit. However, it is important to carefully measure your needs and only order what you need to avoid overpaying for unused material. Moreover, brick ties contribute to the overall thermal performance of the building by preventing heat loss through the cavity. They also aid in maintaining the structural integrity during settlement or subsidence, absorbing any differential movement. Moreover, cow panel fences add a touch of rustic charm to any landscape. Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance

welded steel mesh price. Many suppliers offer discounts for large orders, so buying more mesh at once can reduce the overall cost per unit. However, it is important to carefully measure your needs and only order what you need to avoid overpaying for unused material. Moreover, brick ties contribute to the overall thermal performance of the building by preventing heat loss through the cavity. They also aid in maintaining the structural integrity during settlement or subsidence, absorbing any differential movement. Moreover, cow panel fences add a touch of rustic charm to any landscape. Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance

Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance Their simple, straightforward design and natural color palette blend seamlessly with the surrounding environment, creating a harmonious and aesthetically pleasing appearance cow panel fence. Whether used to outline a garden or to define a property line, cow panel fences add a touch of country elegance to any outdoor space. Installing tall tomato cages is a simple and straightforward process. Once you have chosen the right cages for your garden, place them around the base of each tomato plant and gently guide the vines to grow up through the openings in the cage. As the plants grow, continue to train the vines to grow upwards through the cage, ensuring that they have the support they need to thrive. 1. Create a service class that will handle the video compression logic. This class should have methods for encoding and decoding video streams using Xuggler. Here's an example implementation The Indispensable Role of 250mm Brick Ties in Construction Industry The Comprehensive Wire Mesh Catalogue A Gateway to Unmatched Quality and Versatility Moreover, the spring's end configuration is another critical aspect, as it affects the spring's performance and application suitability. Hooks, loops, or other custom ends can be added to facilitate attachment to other components. Weld mesh sheets are an essential component in modern construction, offering numerous benefits that enhance the strength, durability, and safety of structures. These versatile metal meshes, typically made from mild steel, are designed to be easily welded into place, providing a strong and reliable bond between concrete and the reinforcement bars (rebars) within it. Galvanized iron wire is also commonly used in the electrical industry When choosing a hexagon tomato cage, it's important to consider the size of your plants and the space available in your garden. Cages come in a variety of heights and widths, so be sure to select one that will adequately support your plants as they grow. Some cages also come with adjustable features, allowing you to customize the size and shape to fit your specific needs. Spring hooks are a set of interfaces and annotations that enable developers to tap into different stages of the Spring framework's lifecycle. These hooks provide a way to execute custom code before or after certain Spring-related events occur, such as bean creation, context initialization, or request processing. By leveraging these hooks, developers can extend the functionality of Spring without altering its original source code, promoting modularity and maintainability.

cow panel fence. Whether used to outline a garden or to define a property line, cow panel fences add a touch of country elegance to any outdoor space. Installing tall tomato cages is a simple and straightforward process. Once you have chosen the right cages for your garden, place them around the base of each tomato plant and gently guide the vines to grow up through the openings in the cage. As the plants grow, continue to train the vines to grow upwards through the cage, ensuring that they have the support they need to thrive. 1. Create a service class that will handle the video compression logic. This class should have methods for encoding and decoding video streams using Xuggler. Here's an example implementation The Indispensable Role of 250mm Brick Ties in Construction Industry The Comprehensive Wire Mesh Catalogue A Gateway to Unmatched Quality and Versatility Moreover, the spring's end configuration is another critical aspect, as it affects the spring's performance and application suitability. Hooks, loops, or other custom ends can be added to facilitate attachment to other components. Weld mesh sheets are an essential component in modern construction, offering numerous benefits that enhance the strength, durability, and safety of structures. These versatile metal meshes, typically made from mild steel, are designed to be easily welded into place, providing a strong and reliable bond between concrete and the reinforcement bars (rebars) within it. Galvanized iron wire is also commonly used in the electrical industry When choosing a hexagon tomato cage, it's important to consider the size of your plants and the space available in your garden. Cages come in a variety of heights and widths, so be sure to select one that will adequately support your plants as they grow. Some cages also come with adjustable features, allowing you to customize the size and shape to fit your specific needs. Spring hooks are a set of interfaces and annotations that enable developers to tap into different stages of the Spring framework's lifecycle. These hooks provide a way to execute custom code before or after certain Spring-related events occur, such as bean creation, context initialization, or request processing. By leveraging these hooks, developers can extend the functionality of Spring without altering its original source code, promoting modularity and maintainability. Brick veneer anchors are specialized ties used specifically to attach a brick veneer to a structural backing. These anchors ensure that the aesthetically pleasing brick facade remains securely attached to the underlying structure, which could be wood, steel, or concrete. Brick veneer anchors are designed to accommodate the slight movement that can occur between the veneer and the backing without compromising the integrity of the facade. They come in various designs, including corrugated metal, Z-shaped, and adjustable anchors, each providing different benefits depending on the specific requirements of the project. Proper installation of brick veneer anchors is essential to ensure that the brick facade performs well under various environmental conditions while maintaining its visual appeal.

Heavy Duty Extension Springs

The cost of repairing cavity wall tie failure can vary depending on the extent of the damage and the size of the building. In general, the cost of repairing cavity wall tie failure can range from a few thousand dollars to tens of thousands of dollars. This cost includes not only the replacement of the failed wall ties but also the necessary structural repairs to ensure the stability of the building. In the world of construction, concrete mesh wire has emerged as a highly versatile and durable solution for a wide range of applications. Available for sale at various hardware stores and online platforms, this innovative product offers numerous benefits that make it an essential component in many construction projects. Installation Methods for Wide Cavity Wall Ties One of the most significant advantages of concrete mesh panels is their speed of installation. Unlike traditional concrete forms, which require extensive labor and time to construct and remove, mesh panels can be quickly put into place and filled with concrete. Once the concrete sets, the panels become an integral part of the structure, eliminating the need for additional support systems. This streamlined process leads to faster construction times and lower labor costs. 2. The History and Evolution of Wire Grid Photo Display One key aspect that sets Chinese wire mesh manufacturers apart is their capacity for customization. They can tailor products according to specific requirements, whether it's in terms of size, mesh count, wire diameter, or material. This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations

This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations This flexibility allows them to serve a wide range of customers, from small-scale contractors to large multinational corporations wire mesh manufacturers in china. One of the most popular uses for black craft wire is in jewelry making. Whether you are creating a delicate bracelet or a statement necklace, black wire can be used to add a unique touch to your design. Its dark color can create a dramatic contrast with bright beads or stones, making your jewelry stand out from the crowd. Craft wire is available in an extensive range of gauges, with each gauge indicating its thickness. The lower the gauge number, the thicker the wire. So, a 16 gauge wire is neither too thin nor too thick, providing just the right rigidity for intricate designs without losing its shape or breaking easily. The humble chicken netting fence, a structure often underestimated, stands as a testament to the ingenuity and practicality that agricultural advancements have bestowed upon modern poultry husbandry. This unassuming barrier is not merely a partition; it embodies the principles of safety, efficiency, and sustainability that are paramount in today’s farming practices. 3/8 rib lath is a critical material in the construction industry, particularly in the process of stucco application. It serves as a supportive base for the stucco to adhere to, providing both strength and stability to the exterior walls. This article delves into the intricacies of 3/8 rib lath, its composition, usage, and significance. However, it's essential to consider the impact on ride comfort

wire mesh manufacturers in china. One of the most popular uses for black craft wire is in jewelry making. Whether you are creating a delicate bracelet or a statement necklace, black wire can be used to add a unique touch to your design. Its dark color can create a dramatic contrast with bright beads or stones, making your jewelry stand out from the crowd. Craft wire is available in an extensive range of gauges, with each gauge indicating its thickness. The lower the gauge number, the thicker the wire. So, a 16 gauge wire is neither too thin nor too thick, providing just the right rigidity for intricate designs without losing its shape or breaking easily. The humble chicken netting fence, a structure often underestimated, stands as a testament to the ingenuity and practicality that agricultural advancements have bestowed upon modern poultry husbandry. This unassuming barrier is not merely a partition; it embodies the principles of safety, efficiency, and sustainability that are paramount in today’s farming practices. 3/8 rib lath is a critical material in the construction industry, particularly in the process of stucco application. It serves as a supportive base for the stucco to adhere to, providing both strength and stability to the exterior walls. This article delves into the intricacies of 3/8 rib lath, its composition, usage, and significance. However, it's essential to consider the impact on ride comfort Powder coated wire mesh is a type of fencing material that is coated with a thick layer of powder paint. This process involves applying a dry powder spray to the wire mesh and then heating it to create a strong bond between the paint and the metal surface.

Powder coated wire mesh is a type of fencing material that is coated with a thick layer of powder paint. This process involves applying a dry powder spray to the wire mesh and then heating it to create a strong bond between the paint and the metal surface.