Current location:

Links:

-

In conclusion, the 55x90x23mm bearing is more than just a collection of numbers; it is a symbol of precision engineering and the backbone of countless machines. Its compact size belies its immense importance in facilitating smooth, efficient motion across a diverse range of industries. It underscores the fact that in engineering, even the smallest components can have a significant impact on overall system performance. As technology continues to advance, the role of the 55x90x23mm bearing, and its ilk, will only become more critical in driving progress forward. The 33113X2 bearing boasts several notable features that make it an ideal choice for various applications. Firstly, it is made from high-quality materials, ensuring exceptional strength and durability. Secondly, it features a precision design that reduces friction and heat generation, resulting in increased efficiency and longer bearing life. Additionally, the bearing is available in different sizes and configurations to suit various machinery requirements. Understanding the 6211 bearing specifications opens a portal to appreciating the sophistication embedded in every piece of rotating equipment. From meticulously balanced dimensions to carefully chosen materials and lubrication needs, each specification works in harmony to ensure the bearing's reliability and longevity. Whether in a wind turbine or an electric motor, the 6211 bearing testifies to the engineering prowess that lies behind the scenes, silently powering our world. One of the main advantages of four-row tapered roller bearings is their ability to handle high radial loads due to the increased number of rolling elements. Additionally, because the rollers can move along the length of the raceway, they can accommodate slight misalignments without causing damage to the bearing. This feature makes them particularly useful in situations where precision alignment might be challenging to maintain. Overall, matched tapered roller bearings are a versatile and reliable choice for applications where precise and consistent support is required. Their ability to accommodate misalignment, handle heavy loads, and provide uniform performance makes them a valuable component in many industrial settings. By choosing matched tapered roller bearings for your equipment, you can ensure smooth operation, reduce maintenance costs, and extend the lifespan of your machinery. * Automotive components, such as axles and transmissions The 6212 zz bearing is a standard deep groove ball bearing known for its versatility and reliability. It is widely used in various applications, from electric motors to gearboxes. However, despite its prevalence, understanding the pricing dynamics of this bearing is crucial for procurement managers and engineers alike. The advantages of using the 51100 bearing are numerous. Firstly, it offers increased load capacity and stability, allowing for the use of heavier machinery and reducing the risk of failure. Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life

Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life

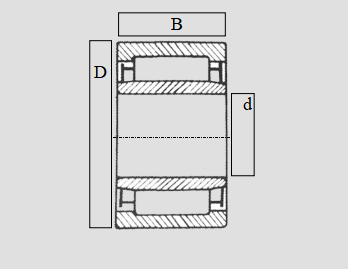

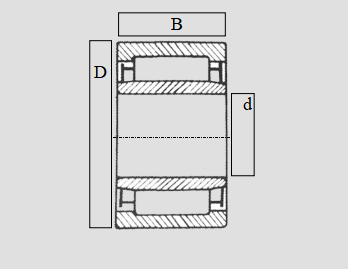

Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life Secondly, its low friction and wear properties result in reduced maintenance costs and longer equipment life 51100 bearing. Thirdly, the 51100 bearing's high speed capabilities make it suitable for use in high-speed applications, such as turbines and compressors. 3. Width (B) The width of the bearing, measured in millimeters or inches. Maintenance of Bearing 51309 The 'NU' prefix in the bearing's designation refers to its design configuration. It signifies a 'free inner ring', meaning the inner ring can move axially relative to the outer ring, thus accommodating shaft expansion. This flexibility is crucial in systems where thermal expansion or dynamic loading may cause changes in the shaft's length. The 6003Z bearing is typically made from high-quality chrome steel (SAE 52100), which provides excellent strength, hardness, and wear resistance. This material composition ensures that the bearing can withstand harsh operating conditions, such as high speeds, heavy loads, and extreme temperatures.

51100 bearing. Thirdly, the 51100 bearing's high speed capabilities make it suitable for use in high-speed applications, such as turbines and compressors. 3. Width (B) The width of the bearing, measured in millimeters or inches. Maintenance of Bearing 51309 The 'NU' prefix in the bearing's designation refers to its design configuration. It signifies a 'free inner ring', meaning the inner ring can move axially relative to the outer ring, thus accommodating shaft expansion. This flexibility is crucial in systems where thermal expansion or dynamic loading may cause changes in the shaft's length. The 6003Z bearing is typically made from high-quality chrome steel (SAE 52100), which provides excellent strength, hardness, and wear resistance. This material composition ensures that the bearing can withstand harsh operating conditions, such as high speeds, heavy loads, and extreme temperatures. In the automotive industry, the 625ZZ finds use in engine components, power steering systems, and even electric motors. Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation

Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation

Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation Its precision engineering ensures minimal vibration and noise, contributing to a smoother and more reliable operation ball bearing 625zz. In the field of robotics and automation, these bearings are instrumental in facilitating the precise movement of axes and gears. Dimensions of the 6006 RS Bearing This innovative bearing boasts a series of enhancements over traditional models. It could feature advanced materials science, employing cutting-edge composites or metal alloys that provide superior strength and resilience. These materials not only extend the bearing's operational lifespan but also improve its load capacity and resistance to extreme temperatures and corrosive environments. Another important feature of deep groove bearings is their self-aligning capability. The bearings are designed with a slight internal clearance, which allows them to adjust to misalignment in the shaft or housing. This is particularly useful in applications where the shaft may experience thermal expansion or other forms of distortion. The Impact of 22232% Price Hike on the Bearing Industry In mining and construction, the 6310zz bearing is utilized in equipment such as crushers, conveyors, and pumps, where it can handle the tough conditions of these industries. The dimensions of the 6310zz bearing ensure that it can support heavy loads and operate smoothly in demanding applications, making it a reliable choice for various industrial needs.

ball bearing 625zz. In the field of robotics and automation, these bearings are instrumental in facilitating the precise movement of axes and gears. Dimensions of the 6006 RS Bearing This innovative bearing boasts a series of enhancements over traditional models. It could feature advanced materials science, employing cutting-edge composites or metal alloys that provide superior strength and resilience. These materials not only extend the bearing's operational lifespan but also improve its load capacity and resistance to extreme temperatures and corrosive environments. Another important feature of deep groove bearings is their self-aligning capability. The bearings are designed with a slight internal clearance, which allows them to adjust to misalignment in the shaft or housing. This is particularly useful in applications where the shaft may experience thermal expansion or other forms of distortion. The Impact of 22232% Price Hike on the Bearing Industry In mining and construction, the 6310zz bearing is utilized in equipment such as crushers, conveyors, and pumps, where it can handle the tough conditions of these industries. The dimensions of the 6310zz bearing ensure that it can support heavy loads and operate smoothly in demanding applications, making it a reliable choice for various industrial needs. In addition to the inner diameter, outer diameter, and width, the 6014 bearing has several other important dimensions and specifications. These include the cage type, material, and lubrication requirements. The cage type, such as steel or polymer, affects the bearing's speed rating and operating temperature range. The material of the bearing, typically chrome steel or stainless steel, determines its strength and durability. Finally, the lubrication requirements, such as grease or oil, must be considered to ensure proper operation and longevity of the bearing. The Bearing 32211 A Comprehensive Guide Beyond the technical details, the catalog also presents Timken's commitment to sustainability and environmental responsibility. The company's bearings are designed with energy efficiency in mind, contributing to reduced carbon footprints in various industries. 33113x2 bearing is a type of bearing that is commonly used in machinery and equipment. It is known for its durability, efficiency, and reliability, making it a popular choice for industrial applications. * Steel and aluminum production Bearings used in rolling mills, extruders, and other equipment in the steel and aluminum industries must be able to withstand high temperatures and corrosive environments. 6216 Bearing Dimensions A Comprehensive Guide Manufacturers and engineers alike appreciate the reliability of the Bearing 627 ZZ. Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike

Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike

Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike Its consistent performance in various environments has made it a go-to choice for heavy machinery and sensitive equipment alike bearing 627 zz. The ZZ shielding not only repels foreign particles but also prevents lubricant from leaking out, thus maintaining the integrity of the system. * Steel and aluminum production Bearings used in rolling mills, extruders, and other equipment in the steel and aluminum industries must be able to withstand high temperatures and corrosive environments. The Evolution and Significance of 4203/202RS Bearings Environmental considerations are also increasingly important in modern industry, and the 6004z bearing aligns well with sustainability efforts Timken, a global leader in bearings and power transmission products, offers an extensive catalog of deep groove ball bearings that cater to a wide range of industrial applications. The Timken deep groove ball bearing catalog is a comprehensive resource for engineers, technicians, and maintenance professionals seeking high-performance and reliable solutions. The 6205 bearing is a high-precision, reliable, and versatile component that offers excellent performance in a wide range of applications. Its precision dimensions, load capacity, low friction, high speed capability, and maintenance-free design make it an ideal choice for engineers and manufacturers seeking durable and efficient solutions for their mechanical systems. In conclusion, while deep groove ball bearings can accommodate some degree of thrust load, their primary strength lies in handling radial loads. For applications requiring substantial thrust capacity, engineers should consider using bearings specifically designed for this purpose or adapting deep groove ball bearings with enhanced features for improved axial load support. Proper selection and configuration of bearings are crucial for ensuring the reliability and efficiency of mechanical systems subjected to complex loading conditions. In conclusion, the 6312 zz bearing is more than just a component; it is a symbol of progress in mechanical systems. Its combination of robust construction, protective sealing, and ease of use makes it an indispensable asset for industries reliant on precision and longevity. As we look towards the future of mechanical innovation, the 6312 zz bearing will undoubtedly continue to play a pivotal role in driving efficiency and dependability across various sectors. Over time, the 22211 k bearing has evolved to meet the growing demands of various industries. Today, it is available in various sizes, load capacities, and specifications, making it suitable for a wide range of applications. Bearing 32211 is a widely used rolling element bearing that finds its application in various industries. This article aims to provide a comprehensive guide on the bearing, including its types, specifications, applications, and maintenance tips. * Aerospace Bearings used in aircraft engines, landing gear, and other critical systems must be able to withstand extreme temperatures and conditions. 、 Features and Specifications 4 One of the key advantages of matched tapered roller bearings is their ability to accommodate misalignment of shafts or housings. This flexibility allows the bearings to operate smoothly and efficiently even in imperfect conditions, helping to reduce wear and extend the lifespan of the equipment they are supporting. Despite their many benefits, deep groove ball bearings do have some limitations. They are generally not suitable for heavy loads or shock loads, as these can cause severe damage to the bearings. Additionally, the installation and alignment of these bearings require careful attention to ensure proper functioning and minimize wear. Navigating the Spherical Roller Bearing Size Chart PDF Brand reputation and warranty also play a role

bearing 627 zz. The ZZ shielding not only repels foreign particles but also prevents lubricant from leaking out, thus maintaining the integrity of the system. * Steel and aluminum production Bearings used in rolling mills, extruders, and other equipment in the steel and aluminum industries must be able to withstand high temperatures and corrosive environments. The Evolution and Significance of 4203/202RS Bearings Environmental considerations are also increasingly important in modern industry, and the 6004z bearing aligns well with sustainability efforts Timken, a global leader in bearings and power transmission products, offers an extensive catalog of deep groove ball bearings that cater to a wide range of industrial applications. The Timken deep groove ball bearing catalog is a comprehensive resource for engineers, technicians, and maintenance professionals seeking high-performance and reliable solutions. The 6205 bearing is a high-precision, reliable, and versatile component that offers excellent performance in a wide range of applications. Its precision dimensions, load capacity, low friction, high speed capability, and maintenance-free design make it an ideal choice for engineers and manufacturers seeking durable and efficient solutions for their mechanical systems. In conclusion, while deep groove ball bearings can accommodate some degree of thrust load, their primary strength lies in handling radial loads. For applications requiring substantial thrust capacity, engineers should consider using bearings specifically designed for this purpose or adapting deep groove ball bearings with enhanced features for improved axial load support. Proper selection and configuration of bearings are crucial for ensuring the reliability and efficiency of mechanical systems subjected to complex loading conditions. In conclusion, the 6312 zz bearing is more than just a component; it is a symbol of progress in mechanical systems. Its combination of robust construction, protective sealing, and ease of use makes it an indispensable asset for industries reliant on precision and longevity. As we look towards the future of mechanical innovation, the 6312 zz bearing will undoubtedly continue to play a pivotal role in driving efficiency and dependability across various sectors. Over time, the 22211 k bearing has evolved to meet the growing demands of various industries. Today, it is available in various sizes, load capacities, and specifications, making it suitable for a wide range of applications. Bearing 32211 is a widely used rolling element bearing that finds its application in various industries. This article aims to provide a comprehensive guide on the bearing, including its types, specifications, applications, and maintenance tips. * Aerospace Bearings used in aircraft engines, landing gear, and other critical systems must be able to withstand extreme temperatures and conditions. 、 Features and Specifications 4 One of the key advantages of matched tapered roller bearings is their ability to accommodate misalignment of shafts or housings. This flexibility allows the bearings to operate smoothly and efficiently even in imperfect conditions, helping to reduce wear and extend the lifespan of the equipment they are supporting. Despite their many benefits, deep groove ball bearings do have some limitations. They are generally not suitable for heavy loads or shock loads, as these can cause severe damage to the bearings. Additionally, the installation and alignment of these bearings require careful attention to ensure proper functioning and minimize wear. Navigating the Spherical Roller Bearing Size Chart PDF Brand reputation and warranty also play a role 22214 bearing price. Well-established brands with a proven track record in the industry often command a higher price due to their reputation for quality and reliable after-sales service. The inclusion of a comprehensive warranty can also hike up the initial investment but provides peace of mind for buyers. The maintenance of 6002 ball bearings is relatively straightforward, involving regular cleaning and lubrication to prevent corrosion and wear. However, it is crucial to handle these bearings with care, as even minor impacts can damage them beyond repair.

22214 bearing price. Well-established brands with a proven track record in the industry often command a higher price due to their reputation for quality and reliable after-sales service. The inclusion of a comprehensive warranty can also hike up the initial investment but provides peace of mind for buyers. The maintenance of 6002 ball bearings is relatively straightforward, involving regular cleaning and lubrication to prevent corrosion and wear. However, it is crucial to handle these bearings with care, as even minor impacts can damage them beyond repair. However, the true value of the 6014 ball bearing lies in its maintenance. Despite its robust construction, it requires minimal upkeep, mainly consisting of regular cleaning and lubrication. This low-maintenance nature reduces operational costs and downtime, increasing overall productivity.

Design and Construction * Install the bearing correctly Ensure that the bearing is installed according to the manufacturer's instructions to prevent misalignment or damage.