Links:

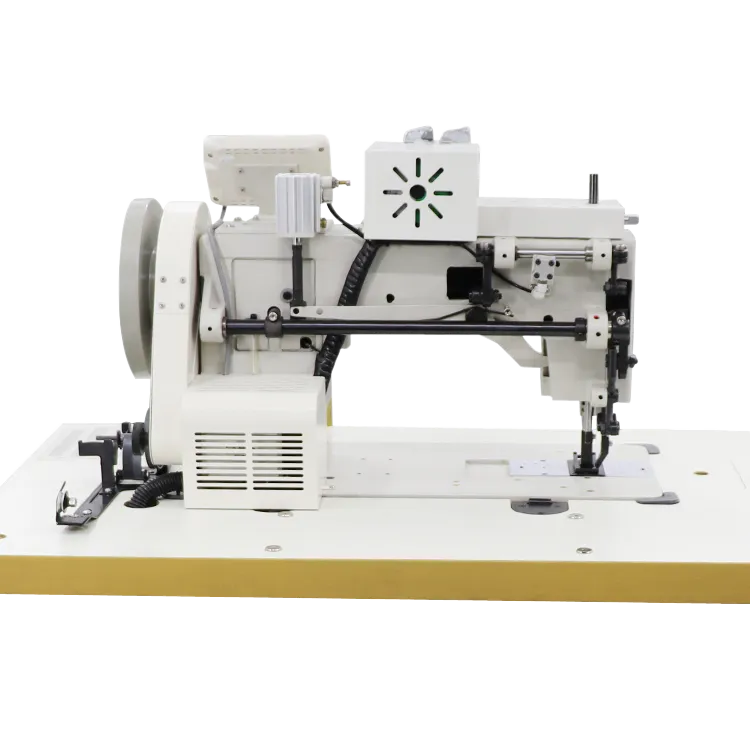

1. Strong Seams One of the most significant advantages of using a double needle machine is the strength of the seams it produces. The dual stitching creates a reinforced seam that is less prone to tearing or fraying, making it ideal for leather items that experience high wear and tear.

If you’re using a zigzag stitch, ensure the width is not wider than the distance between the needles. This prevents the needles from hitting each other, which could lead to breakage.

3. Walking Foot A walking foot is an invaluable accessory for upholstery sewing. It helps in feeding multiple layers of fabric evenly through the machine, preventing puckering and ensuring that your seams are uniform.

3. Insert the Double Needle

Difference Between Heavy-Duty And Industrial Sewing Machines

Discovering the Best 5% Thread Overlockers for Sale

- Practice Before embarking on a large project, it’s advisable to practice on scrap fabric to familiarize oneself with the machine’s capabilities and settings.

Investing in a heavy-duty leather sewing machine can yield numerous benefits. First and foremost, these machines are built for precision and durability. They can produce professional-grade results that are both strong and visually appealing.

Easy Operation and Portability

dressmaker zig zag sewing machine

Looking ahead, the future of bulk bag sewing machines looks promising. As industries continue to grow and evolve, the demand for efficient and reliable packaging solutions will only increase. Companies investing in the latest technologies, such as IoT (Internet of Things) for predictive maintenance and smart manufacturing, will likely lead the way in optimizing production processes and enhancing overall efficiency.

In addition to their use in car manufacturing, automotive sewing machines are also valuable tools for car enthusiasts and DIYers who enjoy customizing their vehicles. With the right machine and some practice, you can create custom upholstery, seat covers, and other interior accessories to personalize your car and make it stand out from the crowd.

Leather is a material that demands robust stitching techniques to ensure longevity. The double needle sewing machine excels in this area, providing a secure stitch that can handle the stress and strain often placed on leather goods. By using two needles, the machine distributes tension evenly across the seam, minimizing the risk of breakage or unraveling. This added durability is crucial for items like belts and bags, which undergo constant use and require dependable construction.

3. Consistent Seam Allowances Maintaining a consistent seam allowance is crucial. A variation as small as 1/8 inch can lead to misalignment. Consider using a quarter-inch foot for accuracy, especially in piecing.

2. Enhanced Fabric Handling The design of the zigzag presser foot allows for better control over the fabric as it moves through the machine. This is particularly beneficial when sewing with stretchy or slippery materials.

Dressmaking is an art form that has been around for centuries, allowing individuals to express their creativity and style through the creation of unique garments. One tool that has revolutionized the world of dressmaking is the dressmaker deluxe zig zag sewing machine.

5. Ease of Use and Maintenance Look for models designed for easy threading and maintenance. Machines that are straightforward to use will minimize downtime and ensure that you can focus on creating rather than troubleshooting.

3. Multiple Stitch Options A double needle machine generally offers various stitch options, from basic straight stitches to more decorative alternatives. This flexibility enables sewists to experiment with different styles and finishes.

3. Heavy-Duty Needles These machines often come with specially designed needles that can penetrate thick fabric layers with ease. The right needle is crucial in upholstery, as it affects the stitch quality and the overall finish of the product.

The versatility of the Cub Leather Sewing Machine makes it suitable for a wide range of applications. Hobbyists can use it for crafting personalized items, while professionals can rely on it for producing high-quality goods on a larger scale. From creating wallets, handbags, and jackets to repairing upholstery, the machine proves itself invaluable in various leatherworking projects.

One of the key advantages of the modern bobbin shuttle hook is its ability to handle a wide range of fabrics, from delicate silks to heavy-duty denim. This versatility is crucial for textile manufacturers who need to adapt to different projects quickly. The precision engineering of the hook ensures that stitches remain consistent, even under varying tensions and fabric types. Additionally, advancements in materials have led to stronger and more durable hooks, thereby extending the lifespan of sewing machines and reducing maintenance costs.

1. Motor Power

Another benefit of long arm upholstery sewing machines is their versatility. These machines come with a variety of built-in stitches and features that make them suitable for a wide range of sewing tasks. From straight stitches to decorative stitches, these machines offer endless possibilities for customization and creativity in upholstery projects.Whether you are sewing garments, home decor, or quilts, a HD sewing machine can help you achieve professional results with less effort. The precision and power of these machines make them a favorite among seamstresses who work with heavy fabrics or multiple layers. With a HD sewing machine, you can confidently take on challenging projects and create beautiful, durable pieces that will stand the test of time.