Links:

Incorporating coloured float glass into design also poses certain challenges. The need for precise color matching, adherence to building codes, and considerations for thermal expansion must be taken into account by architects and builders. However, with advances in technology and a growing pool of expert fabricators, these challenges are becoming easier to navigate. Collaborative efforts between architects, artists, and glass manufacturers are resulting in innovative solutions that push the boundaries of what can be achieved with coloured float glass.

The Evolution and Innovation in Clear Float Glass Manufacturing In conclusion, float glass manufacturing is a testament to human ingenuity and our quest for perfection. It's a delicate dance of physics and chemistry, performed at temperatures that would otherwise be unimaginable. The end result is a product that graces our buildings, protects our vehicles, and enables our technology, all while telling a story of innovation and craftsmanship.

As technology advanced, plastic floats began to replace glass floats as a more cost-effective and practical option. This led to a decline in the use of glass fishing floats, with many fishermen abandoning them in favor of the new, more durable alternatives. However, there are still pockets of traditional fishermen who continue to use glass floats, valuing their beauty and connection to the past.

The Enigma of the Silver Flower Mirror Tempered glass, also known as toughened glass, is a type of safety glass that has been processed to increase its strength and resistance to thermal shock. This unique treatment involves heating the glass to a high temperature and then rapidly cooling it, causing the outer layers to contract and the inner layers to expand. As a result, tempered glass becomes up to five times stronger than ordinary glass and is able to withstand impacts that would shatter regular glass. In the automotive industry, coated float glass is widely used in the production of windshields and windows When it comes to installation, patterned perspex panels are relatively easy to handle and install

patterned perspex panels. They can be cut to size using a saw or laser cutter and attached to walls or ceilings using screws or adhesives. This flexibility allows designers to create custom designs that fit perfectly into any space. In conclusion, the tempered glass process is a marvel of modern technology that turns ordinary glass into a strong, safe, and reliable material. Through careful heating and rapid cooling, the structural integrity of the glass is significantly improved, ensuring that it can serve as a protective barrier in a wide range of environments. Whether it's safeguarding drivers on the road or providing a secure enclosure for a shower, tempered glass stands as a testament to human innovation and the quest for resilience and durability.

patterned perspex panels. They can be cut to size using a saw or laser cutter and attached to walls or ceilings using screws or adhesives. This flexibility allows designers to create custom designs that fit perfectly into any space. In conclusion, the tempered glass process is a marvel of modern technology that turns ordinary glass into a strong, safe, and reliable material. Through careful heating and rapid cooling, the structural integrity of the glass is significantly improved, ensuring that it can serve as a protective barrier in a wide range of environments. Whether it's safeguarding drivers on the road or providing a secure enclosure for a shower, tempered glass stands as a testament to human innovation and the quest for resilience and durability. Low-E glass also offers aesthetic advantages. It allows natural light to fill a space without compromising the view or the quality of light. Moreover, the coatings can help minimize glare and reduce fading of interior furnishings caused by UV exposure, improving the durability and lifespan of interior elements.

Indeed, the aluminum wall mirror transcends mere embellishment; it is an understated piece of art that speaks volumes about modern taste and lifestyle. With its capacity to embellish spaces with a touch of elegance and sophistication, it remains a cherished element in the ever-evolving narrative of home decor. Moreover, the craftsmanship behind these mirrors is a story of skill and tradition

Mirror railings are designed to catch the eye. Unlike traditional wooden or metal railings, a reflective surface adds a unique modern touch to your home. They amplify light, making the space feel more open and airy. This is particularly beneficial in smaller homes or staircases that may otherwise feel cramped. When light reflects off a mirror railing, it creates a dazzling effect that can brighten up any area and make the staircase a visually striking part of your home.

In conclusion, Low-E glass is a versatile and sustainable solution for those seeking to improve the energy efficiency and aesthetic appeal of their homes. Its ability to balance light transmission with thermal insulation, coupled with its wide range of styles and finishes, makes it an ideal choice for anyone looking to create a comfortable and environmentally friendly living space. The acid used in this process, typically hydrofluoric acid, reacts with the glass's surface, eating away at the outer layer to create a textured effect. The duration of the acid exposure determines the degree of etching, which can range from light frosting to a deeper, more pronounced texture. This controlled corrosion process requires precision and skill, as the timing and concentration of the acid must be carefully monitored to achieve the desired aesthetic. The process of tempered acid-etching involves several steps. First, the glass is heated to a high temperature to soften it, a process called annealing. Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking

Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking

Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking Next, the glass is cooled rapidly, a technique called tempering, which strengthens the glass and makes it more resistant to cracking tempered acid etched glass. After tempering, the glass is etched using a mixture of acid and water. The acid eats away at the glass, creating the desired design, while the water helps to remove any residue left behind. In the world of modern architecture and interior design, the significance of materials that offer both aesthetic appeal and functional benefits cannot be overstated. One such material that has increasingly gained popularity in recent years is low e soft coat glass. This innovative type of glass combines a delicate balance of form and function, making it an ideal choice for a variety of applications. Challenges and Secrets Apart from privacy, tinted glass also offers several aesthetic benefits

tempered acid etched glass. After tempering, the glass is etched using a mixture of acid and water. The acid eats away at the glass, creating the desired design, while the water helps to remove any residue left behind. In the world of modern architecture and interior design, the significance of materials that offer both aesthetic appeal and functional benefits cannot be overstated. One such material that has increasingly gained popularity in recent years is low e soft coat glass. This innovative type of glass combines a delicate balance of form and function, making it an ideal choice for a variety of applications. Challenges and Secrets Apart from privacy, tinted glass also offers several aesthetic benefits tinted glass colors. It can add a touch of style and sophistication to any room, making it an excellent addition to modern interiors. The wide range of colors and shades available ensures that you can find a tint that perfectly matches your personal taste and decor. Whether you prefer a subtle, neutral tone or a bold, vibrant color, there is a tinted glass option to suit your needs.

tinted glass colors. It can add a touch of style and sophistication to any room, making it an excellent addition to modern interiors. The wide range of colors and shades available ensures that you can find a tint that perfectly matches your personal taste and decor. Whether you prefer a subtle, neutral tone or a bold, vibrant color, there is a tinted glass option to suit your needs. Quality control is paramount in this process, as even minor imperfections can lead to significant flaws in the final product. Automated systems are often employed to monitor thickness and detect any anomalies during production. Once the glass sheets have cooled and been cut to size, they undergo further treatments if necessary, such as polishing, coating, or laminating.

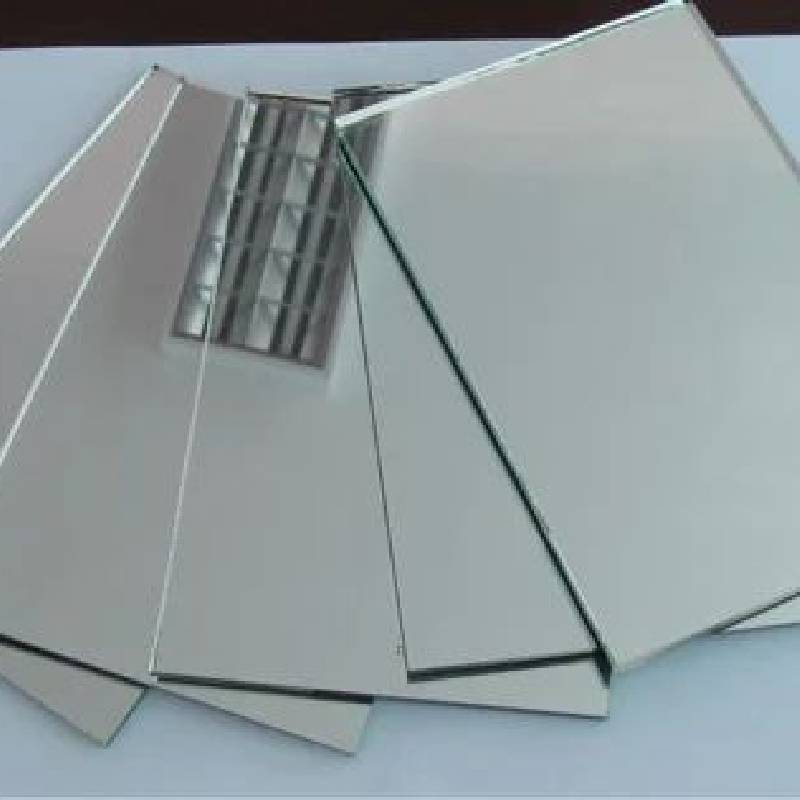

In recent years, frosted glass has seen a resurgence in popularity, driven by a growing trend towards minimalism and a desire for open, yet living spaces The Ephemeral Art of Clear and Frosted Glass In terms of maintenance, aluminium framed mirrors are relatively easy to clean and maintain. Simply wipe down the frame with a damp cloth and a mild cleaning solution to keep your mirror looking shiny and new. Float glass is known for its optical clarity, making it an ideal choice for windows and display cases where visibility is important. Its smooth and uniform surface also allows for easy cleaning and maintenance, making it a practical option for any application. In addition, float glass is stronger and more durable than other types of glass, making it resistant to breakage and deformation. One of the most common types of reflective glass is tinted reflective glass. As the name suggests, this type of glass has a tinted coating that helps to reduce glare and heat from the sun. It is commonly used in buildings with large windows or glass facades to improve energy efficiency and provide a more comfortable indoor environment. Tinted reflective glass is available in a range of colors, allowing designers to achieve a specific look or match the overall color scheme of a building.

The Enigmatic Beauty of Reflective Mirror Glass

The common photovoltaic glass substrate mainly uses ultra-white glass, including ultra-white float glass and ultra-white rolled glass. Compared with ordinary glass, ultra-white glass has a very low iron content, whiter color, lower self-detonation rate, and higher hardness, so it meets the requirements of photovoltaic glass with higher light transmittance, flatness, chemical stability, thermal stability, etc., and has the following characteristics:

But this mirror was not just a pretty face. Its full-length design allowed me to see myself in all my glory, from head to toe. No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure

No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure No longer did I have to crane my neck or contort my body to get a glimpse of my entire figure aluminum full length mirror. With this mirror, I could see myself as I truly was, without any distortion or illusion. Float glass, an innovation that revolutionized the glass industry, is a type of sheet glass manufactured using the float process. This method, developed in the early 20th century, has become the standard for producing high-quality, flat glass worldwide. One prominent variant in this category is the 8mm float glass, a popular choice for various applications due to its exceptional properties. The Elegance of Acid-Etched Frosted Glass In conclusion, frit pattern glass is a timeless art form that continues to inspire and captivate people around the world. Its beauty, versatility, and functionality make it a versatile medium that is well-suited for a wide range of applications. Whether you are an artist or a collector, frit pattern glass is sure to add a touch of elegance and sophistication to any space. Applications of Reflective Glass Red frosted glass is a unique and eye-catching design choice that is sure to make a statement in any space. This bold and vibrant material adds a pop of color and personality to a room, while also providing functional benefits. Moreover, Low-E glass is available in a variety of styles and finishes, making it suitable for use in both traditional and contemporary designs

aluminum full length mirror. With this mirror, I could see myself as I truly was, without any distortion or illusion. Float glass, an innovation that revolutionized the glass industry, is a type of sheet glass manufactured using the float process. This method, developed in the early 20th century, has become the standard for producing high-quality, flat glass worldwide. One prominent variant in this category is the 8mm float glass, a popular choice for various applications due to its exceptional properties. The Elegance of Acid-Etched Frosted Glass In conclusion, frit pattern glass is a timeless art form that continues to inspire and captivate people around the world. Its beauty, versatility, and functionality make it a versatile medium that is well-suited for a wide range of applications. Whether you are an artist or a collector, frit pattern glass is sure to add a touch of elegance and sophistication to any space. Applications of Reflective Glass Red frosted glass is a unique and eye-catching design choice that is sure to make a statement in any space. This bold and vibrant material adds a pop of color and personality to a room, while also providing functional benefits. Moreover, Low-E glass is available in a variety of styles and finishes, making it suitable for use in both traditional and contemporary designs One of the most common applications for tempered glass in the wholesale market is for electronic devices such as smartphones and tablets Grey float glass, a versatile and timeless material, has been a staple in architecture and design for decades. Its unique characteristics make it an ideal choice for a wide range of applications, from commercial buildings to residential spaces.

One of the most common applications for tempered glass in the wholesale market is for electronic devices such as smartphones and tablets Grey float glass, a versatile and timeless material, has been a staple in architecture and design for decades. Its unique characteristics make it an ideal choice for a wide range of applications, from commercial buildings to residential spaces. In addition to mirrors, mirror glass material is also used in the automotive industry. Many vehicles have side mirrors and rearview mirrors made of mirror glass material to provide drivers with a clear view of their surroundings. The reflective properties of mirror glass material help improve visibility and safety on the road, reducing the risk of accidents

mirror glass material. One of the key features of solar control low e glass is its reflective coating, which helps to reflect a large portion of the sun's heat and light away from the building. This not only helps to keep the interior of the building cooler in the summer months but also helps to reduce the need for air conditioning, resulting in lower energy bills and a smaller carbon footprint. Beyond functionality, reflective glass serves as a canvas for Chinese artisans. During festivals, buildings are illuminated with vibrant colors and patterns, turning ordinary days into celebrations of culture and tradition. The glass becomes a medium through which stories of old are told anew, connecting generations in a visual symphony of light and reflection. The burnished silver mirror was not just an object; it was a portal to a world where history and mystery intertwined. Its polished surface had reflected the faces of countless individuals over the centuries, each leaving behind a whisper of their soul. It had witnessed joy and heartache, celebrations and farewells, all captured in its meticulously polished silver. In conclusion, iGu Glass is much more than a novelty; it's a testament to human ingenuity and our relentless pursuit of convenience and innovation. As this technology continues to evolve, we can expect to see it integrated into every facet of our lives, making our environments more engaging, accessible, and intuitive. The era of interactive glass has arrived, and iGu Glass is leading the charge. There is something truly enchanting about the intricate designs and craftsmanship of antique silver mirrors. Each mirror tells a story of a bygone era, reflecting the style and glamour of the time it was created. Whether it's a ornate Victorian mirror or a sleek Art Deco piece, antique silver mirrors have a timeless appeal that never goes out of style.

Check whether the fireproof structure is set, and check the laying and thickness of the fireproof cotton.

Lastly, installation charges must be factored in. Installing tempered glass often requires professional services due to its delicate nature and specific handling requirements. These labor costs can vary based on location, difficulty of installation, and whether additional services like removal of old glass or framing are needed. The journey of Low-E glass in China began in the late 1990s when the first domestic Low-E glass production line was established. Since then, the industry has grown exponentially, driven by government policies promoting green buildings and the increasing awareness among consumers about energy-saving solutions. Today, China is not only a major consumer but also a leading producer of Low-E glass, accounting for a substantial share of the global market. The Elegance of Acid-Etched Frosted Glass OEM tinted glass is a type of glass that has been specially treated to block out a certain amount of light and heat. This type of glass is often used in vehicles and buildings to help reduce glare, protect the interior from UV rays, and improve overall aesthetic appeal. Overall, the price of 4mm float glass is a key consideration when choosing glass for a project. By understanding the factors that influence the price, as well as the specific requirements of the application, it is possible to make an informed decision that balances cost and quality. With its versatility, strength, and affordability, float glass remains a popular choice for a wide range of applications in the construction industry. The Enchanting Silver Bubble Mirror A Reflection of Beauty and Mystery