Links:

Advantages of Stainless Steel Foundation Bolts

Conclusion

However, chemical studies also pose ethical and safety concerns, emphasizing the need for responsible scientific practices. The potential misuse of chemical knowledge can lead to detrimental consequences, highlighting the importance of ethical guidelines and regulations. 3. Ensure that the deck surface is clean and free from debris before installing the anchors. In the realm of construction, stability is paramount. It ensures the structural integrity of buildings, bridges, and other structures, providing safety and reliability for those who use them. Wedge anchors and bolts are two essential components that work together to provide this stability.

4. Mechanical and Electrical Installations Resin anchor studs are useful for securing electrical boxes, HVAC units, and machinery in place, especially in industrial settings where vibrations and movements are common.

1. Corrosion Resistance The primary feature of galvanized Tek screws is their resistance to rust and corrosion. This makes them ideal for outdoor applications and structures exposed to harsh weather conditions.

In addition to their strength and durability, resin anchors for concrete are also known for their versatility. They can be used in a wide range of temperature and environmental conditions, making them suitable for both indoor and outdoor applications. Furthermore, resin anchors are available in various sizes and configurations, allowing for customization to meet the specific requirements of different concrete structures.

resin anchors for concrete

One of the key benefits of using these screws is their ability to reduce the risk of material damage

A hex head self-drilling screw is a type of screw that incorporates a hexagonal head, allowing it to be driven with a wrench or socket, offering greater torque and stability during installation. The self-drilling feature means that the screw has a unique point design that allows it to drill its own pilot hole in materials like metal, wood, and plastic without the need for pre-drilling. This eliminates the need for additional tools and saves time, making it an efficient choice for various applications.

In conclusion, steel lateral bracing plays a vital role in modern construction by providing essential support against lateral forces. Its strength, durability, and adaptability make it an indispensable component in ensuring the safety and longevity of buildings. As technology advances and construction methods evolve, the importance of innovative and efficient lateral bracing solutions will continue to grow, further underscoring their critical role in structural engineering.

4. Reusability Many concrete contractors strive for sustainability and cost-effectiveness. Wedge bolts can often be reused multiple times within different projects, provided they are properly maintained and inspected after each use. This reusability contributes to reducing waste and lowering overall material costs.

The introduction of black phosphate drywall screws marks a significant advancement in the fastener industry, providing a reliable and aesthetically pleasing solution for drywall installations. Their corrosion resistance, enhanced grip, and efficient installation process make them a favorite among contractors and builders. As the industry continues to innovate, it's likely that these screws will play an integral role in shaping the future of construction, offering a blend of performance and visual appeal that meets the contemporary needs of the market. Whether you are a DIY enthusiast or a seasoned professional, incorporating black phosphate drywall screws into your toolkit is a savvy choice that promises to deliver consistent results in your projects.

Furthermore, hammer head T bolts are easy to maintain and replace when necessary. Their simple design and ease of installation mean that they can be quickly swapped out or upgraded without the need for specialized tools or equipment. This makes them a cost-effective solution for businesses looking to streamline their maintenance processes. When selecting structural bolts for a project, it is important to consider the specific requirements and load-bearing capabilities of the application. A325 bolts are typically used in high-stress applications where shear strength and tensile strength are critical, such as in the construction of bridges, buildings, and other structures.

2. Corrosion Resistance Many chemical anchor systems are designed to resist corrosion, making them ideal for outdoor or highly humid environments.

1. Material and Coating Fasteners should be made from materials that resist corrosion and wear, especially if the finished product is subjected to moisture. Coated fasteners, such as zinc or epoxy-coated, can offer additional protection.

While steel stud bracing is an essential part of many construction projects, it is important to ensure that it is installed correctly to maximize its benefits. Proper bracing spacing, connections, and anchoring are all key factors in ensuring the stability and reliability of the structure. Working with experienced professionals who understand the importance of steel stud bracing can help ensure that your building meets all safety and performance standards.

The term 8% drywall screw often refers to the specific design and characteristic of the screws being utilized in drywall applications, particularly around their strength, coating, or other physical properties. While the 8% designation might suggest a particular dimensional standard or a specific specification relevant to certain applications, it's essential to understand that there are various types and qualities of drywall screws available.

Resin anchor bolts, also known as chemical anchor bolts, are essential components used in construction and engineering projects. These bolts are widely used for securing heavy loads and providing strong structural support in various applications. Among the various sizes available, M10 resin anchor bolts are commonly used in medium-duty applications. When it comes to installation, security tek screws are easy to use with the right tools. Simply select the correct security bit for the screw, insert it into the screw head, and tighten or loosen as needed. This straightforward installation process ensures that security tek screws can be quickly and efficiently installed in a variety of settings. Moreover, hex timbr screws are made from high-quality steel, which ensures they are both durable and resistant to corrosion

3. Aesthetic Uniformity Galvanized screws have a clean, metallic finish that blends well with various materials, contributing to the overall aesthetic of a project.

Moreover, butterfly bolts offer a clean and professional finish since they don't require access from behind the wall. This feature makes them perfect for situations where the backside of the wall is not accessible, such as in finished basements or when attaching items to an exterior wall.

In summary, bracing steel beams are crucial for ensuring the safety and longevity of modern structures. Their ability to withstand lateral forces makes them an indispensable element in the design of buildings located in vulnerable regions. Through innovative design and advanced materials, bracing systems not only enhance structural performance but also contribute to the overall beauty of architectural projects. As technology continues to advance, the future of bracing in construction promises even greater efficiencies and capabilities, ensuring that our buildings remain safe and resilient for generations to come.

One of the key features of high tensile hex head bolts is their strength and durability. Made from high-quality materials such as carbon steel, alloy steel, and stainless steel, these bolts are able to withstand extreme conditions and environments. This makes them ideal for use in applications where high levels of tension and pressure are present.

Considerations When Using Fine Thread Screws

The 16mm Tek Screws A Comprehensive Guide The M10 double end threaded stud is typically made from high-quality materials such as stainless steel or carbon steel, ensuring durability and strength. Its design consists of threaded ends on both sides, allowing for easy installation and removal. The M10 designation indicates the thread size and pitch, with M10 being the metric standard for a 10mm diameter thread. Beyond aesthetic considerations, white tek screws offer significant functional advantages. Their durability ensures that they can withstand the test of time, even in harsh environments. They are resistant to temperature extremes, UV radiation, and chemical attacks, ensuring longevity in settings such as marine applications, high-humidity areas, or places where chemicals are present. One of the main advantages of self screwing concrete screws is their ease of use. Unlike traditional anchors that require pre-drilling and a separate anchor piece, self screwing concrete screws can be easily installed with just a power drill. This saves time and effort during the installation process, making them a popular choice for contractors and DIY enthusiasts alike. One of the key features of wafer head self-drilling screws is their wafer-shaped head, which has a low profile and provides a flush finish once the screw is fully driven into the surface. This makes them ideal for use in applications where a sleek and professional appearance is desired. The primary function of steel stud wall bracing is to provide lateral support to walls, which are often subjected to significant forces due to their height and the weight they bear. Without proper bracing, walls can bow, twist, or even collapse, leading to serious structural damage and potential safety hazards. By contrast, steel stud wall bracing enhances the overall strength and resilience of walls, allowing them to withstand harsh environmental conditions and withstand the test of time. One of the key benefits of stainless steel resin anchor bolts is their versatility. They are suitable for a wide range of applications, from securing handrails and guardrails to fixing machinery and equipment. Their high load-bearing capacity and quick installation process make them a popular choice among contractors and engineers. How to Install Threaded Rod Chemical Anchors The Versatility of M16 Concrete Anchors in Modern Construction Another important aspect of bonded washer screws is their versatility. They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings

They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings

They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings They can be used in a wide range of materials, including steel, stainless steel, aluminum, and plastic, making them suitable for use in various industrial settings bonded washer screws. Additionally, they are available in different sizes and shapes, allowing engineers to choose the most appropriate option based on their specific requirements. In conclusion, anchor bolt wedge types are a reliable and durable option for securing objects to concrete or masonry. With their ease of installation, strength, and versatility, wedge anchor bolts are a popular choice for a wide range of construction applications. By following proper installation procedures, users can trust in the security and stability provided by wedge anchor bolts in their projects. Another benefit of hex drive timber screws is their corrosion resistance

bonded washer screws. Additionally, they are available in different sizes and shapes, allowing engineers to choose the most appropriate option based on their specific requirements. In conclusion, anchor bolt wedge types are a reliable and durable option for securing objects to concrete or masonry. With their ease of installation, strength, and versatility, wedge anchor bolts are a popular choice for a wide range of construction applications. By following proper installation procedures, users can trust in the security and stability provided by wedge anchor bolts in their projects. Another benefit of hex drive timber screws is their corrosion resistance

hex drive timber screws. Many hex drive timber screws are coated with a protective layer that helps prevent rust and corrosion, prolonging the lifespan of the screw and the connection it creates. This makes them suitable for outdoor applications where they may be exposed to moisture and other harsh elements. Once the concrete has been poured and has set, the next step is to fix the bolts securely into place. This is typically done using a combination of nuts, washers, and epoxy resin. The bolts are threaded through the nuts and washers, and then tightened to the specified torque to ensure a secure fit. Understanding the Power and Versatility of 10 x 1 Self-Drilling Screws

Another benefit of double sided stud bolts is their reliability

double sided stud bolt. When properly installed, they provide a high level of resistance to tension and shear forces, ensuring that the components remain securely fastened together. This makes them ideal for use in applications where durability and stability are essential.

1. Correct Drilling Depth The hole drilled in the concrete should be of the correct depth and diameter to accommodate the specific anchor bolt being used.

One common type of self-drilling screw is the pan head screw. This type of screw has a flat, disc-shaped head that sits flush with the surface of the material being fastened. Pan head screws are often used in applications where a smooth finish is desired, such as in metal roofing or siding installation. In addition to their ease of use, self-tapping metal screws are also known for their strength and durability. Made from high-quality materials such as stainless steel or hardened steel, these screws are designed to withstand heavy loads and resist corrosion. This makes them ideal for outdoor applications where they may be exposed to the elements. In the manufacturing sector, long tek screws find application in assembling heavy machinery and equipment The importance of foundation bolts and nuts lies not just in their mechanical function but also in their potential impact on safety. A loose or improperly installed bolt can lead to catastrophic failures, compromising the entire structure. Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications

Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications Thus, their installation requires meticulous planning, precise measurements, and strict adherence to engineering specifications foundation bolt nut.

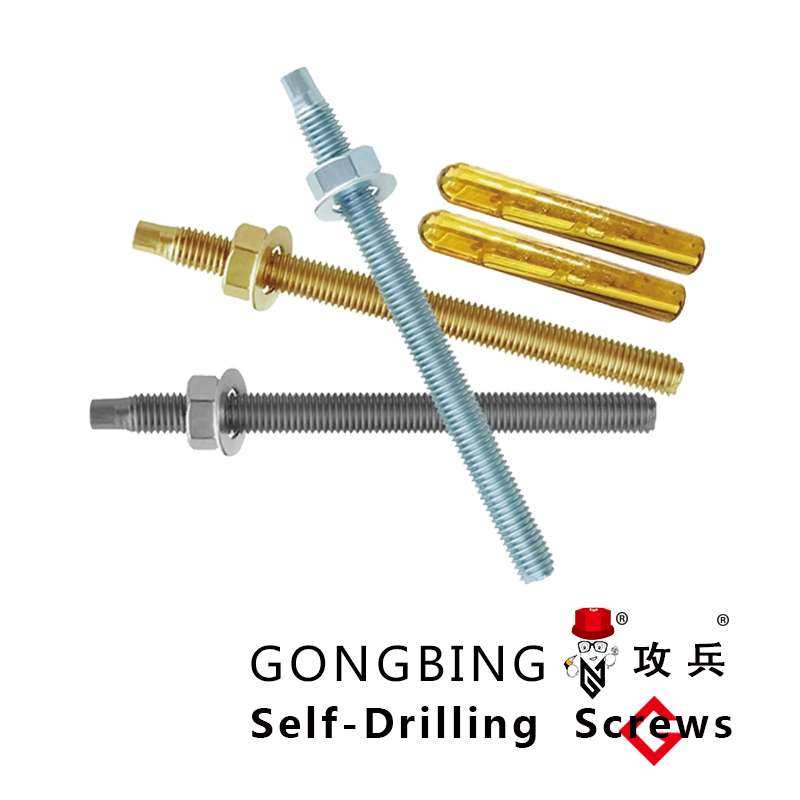

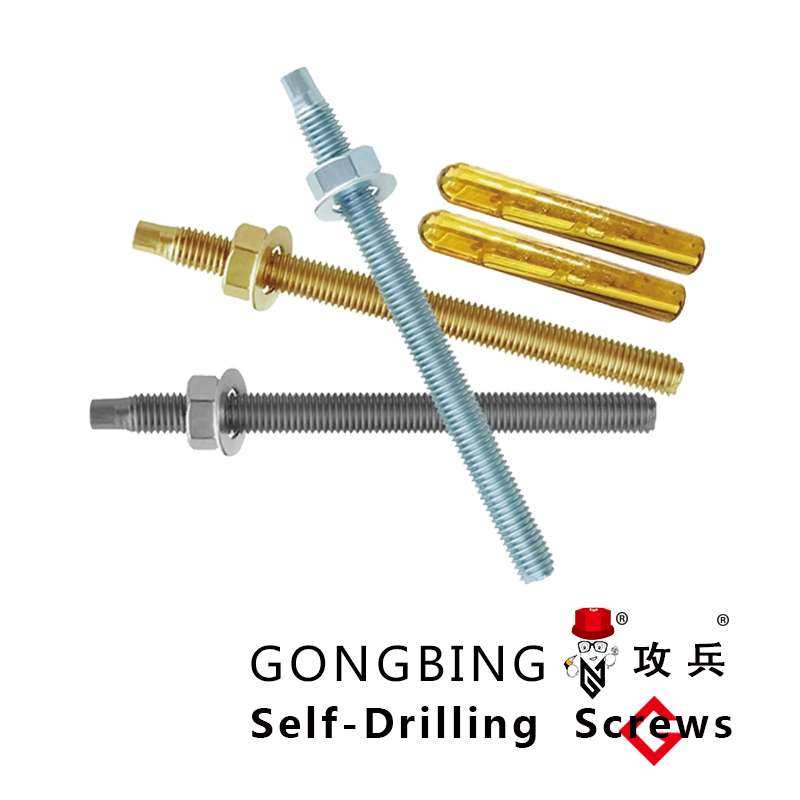

foundation bolt nut. 1. No Pre-Drilling Required One of the most significant advantages of self-drilling screws is that they eliminate the need for pre-drilled holes. This feature not only saves time during installation but also reduces labor costs, making them ideal for large-scale projects.