Links:

-

In addition to its primary use in electrical insulation, rubber insulation tape finds applications in other industries too

- Extreme Temperature Resistance – Polyimide has exceptional resistance to high temperatures. It can withstand extreme heat, making it suitable for applications in industries such as aerospace, automotive, or electronics, where exposure to extreme temperatures is common.

Rubber tapes are generally non-adhesive, and are either equipped with a liner or are linerless. Stretched and overlapped layers will fuse or bond together to form an effective electrical insulation and moisture barrier. For low-voltage (1000V or less) applications, rubber tapes should be stretched during wrapping so that tape width is reduced to approximately 75%. For high- and medium-voltage applications — where the electrical stresses are high (e.g. connector areas, lug areas, and cable shield cut-back areas) — tape should be stretched just short of its breaking point.

emergency exit floor markings. In some buildings, they may extend to stairwells, highlighting steps to prevent slips, trips, or falls. One of the key advantages of 3M vulcanizing tape is its versatility

emergency exit floor markings. In some buildings, they may extend to stairwells, highlighting steps to prevent slips, trips, or falls. One of the key advantages of 3M vulcanizing tape is its versatility Furthermore, rubber seal strips are used in a variety of other applications, such as in appliances, electronics, and industrial machinery. These strips help to provide protection against moisture and dust, as well as to dampen vibrations and reduce noise levels. In the automotive industry, rubber seal strips are used to seal body panels, windows, and sunroofs, providing a watertight and airtight seal. 4. Securing Equipment It can be used to secure equipment and machinery in place, preventing unwanted movement or displacement.

Furthermore, rubber seal strips are used in a variety of other applications, such as in appliances, electronics, and industrial machinery. These strips help to provide protection against moisture and dust, as well as to dampen vibrations and reduce noise levels. In the automotive industry, rubber seal strips are used to seal body panels, windows, and sunroofs, providing a watertight and airtight seal. 4. Securing Equipment It can be used to secure equipment and machinery in place, preventing unwanted movement or displacement.

The power supply unit links your control box to your main supply or power source. It also ensures that the power comes within the ideal current and voltage ranges thereby protecting your linked devices.

Moreover, the 'Seal' in Flex Seal Tape refers to its waterproofing capabilities. Once applied, it creates an airtight and watertight barrier, preventing leaks, moisture ingress, and water damage. It's a reliable solution for repairing pipes, roofs, gutters, or even pool liners, offering long-lasting protection against water intrusion. In the realm of electrical insulation and sealing solutions, one product that stands out prominently is the Seal It Silicone Insulation Tape. This innovative tape has revolutionized the way we approach electrical insulation, waterproofing, and repair tasks, offering a robust and reliable solution for a multitude of applications. 2. Retractable Tape This tape features a spring-loaded mechanism that allows it to be easily extended and retracted as needed. It is particularly useful for temporary hazards or when frequent repositioning is required.In addition to its practicality, the tape's durability sets it apart from other insulation solutions. 3M HT Insulation Tape is resistant to abrasion, chemicals, and moisture, making it suitable for both indoor and outdoor use. This resilience ensures that it can withstand harsh environmental conditions without compromising its structural integrity. As a result, businesses can rely on this product to maintain operational efficiency and safety, even in challenging situations.

Introduction Overall, PVC tape is a valuable tool that can be used in a wide range of applications. Its strong adhesive properties, colorful appearance, and versatility make it an essential item for any toolbox or workspace. Whether used for electrical insulation, bundling packages, labeling, or automotive repairs, PVC tape is a reliable and handy tool that can help get the job done efficiently and effectively. Furthermore, insulation tape is also a valuable tool for crafting and DIY projects

Butyl rubber rolls find applications in many areas, including automotive, construction, and consumer products. One of the most common uses is in the automotive industry, where butyl rubber is employed in manufacturing inner tubes for tires, gaskets, and seals. Its impermeability helps to reduce air leakage, enhancing tire performance and longevity.

butyl rubber roll

Moreover, butyl rubber rolls are employed in medical applications, such as in the production of medical devices and pharmaceutical packaging. The material's non-reactive nature ensures that it does not interact with medications, making it safe for storing sensitive substances.

In the automotive sector, butyl foil tape is often employed for sound dampening and insulation purposes. Its ability to stick to metal, plastic, and glass surfaces makes it a go-to solution for noise reduction and vibration control in vehicles. It's also used for repairing and sealing automotive body parts, providing a reliable and efficient fix.

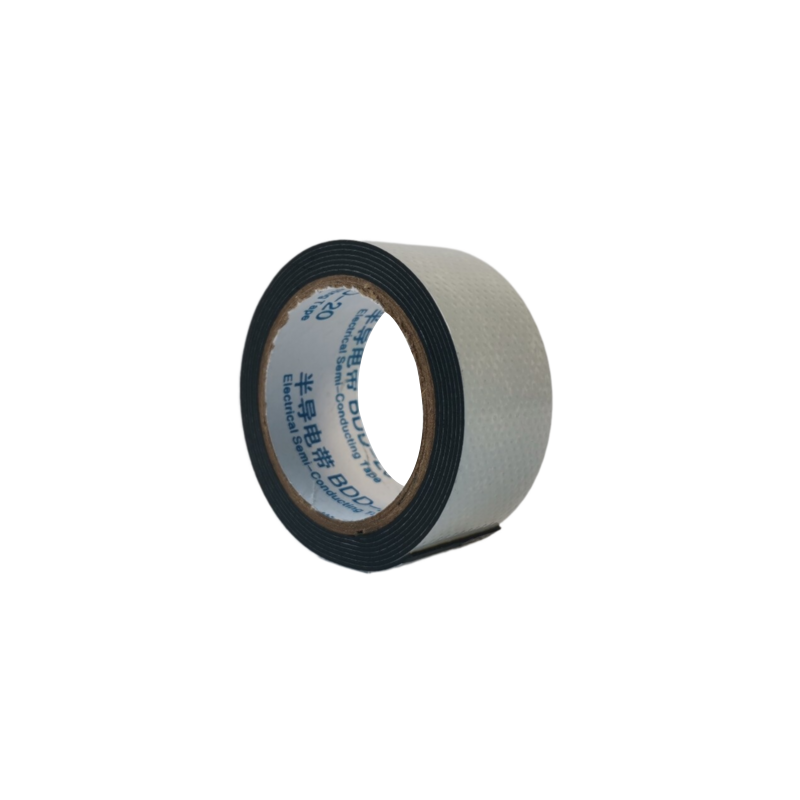

Linerless Insulating Rubber Tape

Made with a specialized high-temperature tempering process, butyl tape is thoroughly airtight and watertight to endure the harshest of weather conditions - from heavy rains to frigid winters, and its UV resistance helps to withstand direct sunlight with minimal damage.

Moreover, Flex Tape is resistant to extreme temperatures, which plays a vital role in its effectiveness. Whether it is the frigid cold of winter or the sweltering heat of summer, the tape maintains its adhesive properties, ensuring that repairs remain intact throughout the year. This reliability brings peace of mind to users who rely on it for critical fixes.

Furthermore, this type of tape has a good tensile strength and conformability, allowing it to adhere effectively to irregular surfaces and corners. It can easily wrap around wires and cables, providing a snug fit that seals out moisture and dust. The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind

The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind The pressure-sensitive adhesive ensures a secure bond, while still allowing for easy removal when necessary, without leaving residue behind pvc insulation tape black.

pvc insulation tape black. Code: XF-KJD

Polyethylene Tape, or PE Tape, is a type of adhesive tape made from polyethylene, a durable and versatile thermoplastic polymer. It finds a wide range of applications due to its various properties and benefits.

Its durability ensures that the tape remains in place even under extreme conditions, making it a reliable solution for long-term insulation needs Its durability ensures that the tape remains in place even under extreme conditions, making it a reliable solution for long-term insulation needs

Its durability ensures that the tape remains in place even under extreme conditions, making it a reliable solution for long-term insulation needs Its durability ensures that the tape remains in place even under extreme conditions, making it a reliable solution for long-term insulation needs insulation black tape. Yet, perhaps the most remarkable aspect of self-amalgamating tape lies in its accessibility. Unlike many specialized tools, scotch tape is ubiquitous, making the technology behind self-amalgamation accessible to anyone with a roll in hand. This democratization of a sophisticated technology is a testament to its design, intended not for exclusivity but to enhance everyday tasks with ease and efficiency.

insulation black tape. Yet, perhaps the most remarkable aspect of self-amalgamating tape lies in its accessibility. Unlike many specialized tools, scotch tape is ubiquitous, making the technology behind self-amalgamation accessible to anyone with a roll in hand. This democratization of a sophisticated technology is a testament to its design, intended not for exclusivity but to enhance everyday tasks with ease and efficiency. Another emerging application of flame retardant tapes is in the realm of renewable energy, particularly in the installation of solar panels and wind turbines. These installations often require materials that can withstand high temperatures and environmental stresses. Flame retardant tapes provide essential protection in these settings, helping to maintain the integrity and safety of the energy generation systems.

There are numerous benefits to using door seal tape, including Butyl rope caulk is a versatile and highly useful product that is essential for various sealing and weatherproofing applications. This type of caulk is made from butyl rubber, a synthetic rubber known for its flexibility, durability, and resistance to temperature changes. Butyl rope caulk is commonly used in construction, automotive, marine, and other industries where a strong and durable seal is required. However, like any product, rubber tape does have its limitations. While it is excellent for stopping minor leaks and providing a short-term solution, it may not be the best choice for large-scale plumbing issues or long-term fixes. In such cases, consulting with a professional plumber would be advisable. Additionally, rubber tape should not be used on gas lines due to the risk of obstructing critical ventilation pathways. Another advantage of rubber car door seal strips is their durability and longevity

In the realm of industrial materials and engineering, the significance of 130C linerless rubber splicing tape cannot be overstated. This innovative product has revolutionized the way we approach bonding, sealing, and repair tasks, particularly in high-temperature environments. Its unique features and benefits have made it a go-to solution for numerous industries, from construction to automotive, aerospace, and manufacturing. Almost everything on the control panel is powered by its circuit breaker. Typically, this circuit breaker includes a connection on the panel's exterior that enables us to turn off the electricity.

In the realm of industrial materials and engineering, the significance of 130C linerless rubber splicing tape cannot be overstated. This innovative product has revolutionized the way we approach bonding, sealing, and repair tasks, particularly in high-temperature environments. Its unique features and benefits have made it a go-to solution for numerous industries, from construction to automotive, aerospace, and manufacturing. Almost everything on the control panel is powered by its circuit breaker. Typically, this circuit breaker includes a connection on the panel's exterior that enables us to turn off the electricity.Never forget that the circuit breaker's top always has electricity. The input voltage to the panel can range from 480 volts down to 120 volts or less.