Links:

One of the most exciting aspects of jumbo belts is their versatility in styling. They can be paired with various outfits, from casual to formal. For a casual look, a jumbo belt can be worn over an oversized sweater and high-waisted jeans, adding definition to the silhouette. As for a more formal appearance, draping a jumbo belt over a tailored dress can create a polished and sophisticated look, perfect for special occasions.

In summary, gunny bag sewing machines are a crucial element of manufacturing operations across various industries. Their ability to enhance efficiency, ensure durability, and contribute to eco-friendly practices makes them indispensable in today’s industrial ecosystem. As the demand for sustainable packaging solutions continues to grow, the role of gunny bag sewing machines in supporting these initiatives becomes ever more significant. As businesses seek to adapt to evolving market trends, investing in such specialized machinery will undoubtedly yield fruitful returns in efficiency and sustainability.

One of the most popular and highly rated computerized sewing and embroidery machines is the Brother SE1900. This machine is known for its user-friendly interface, wide range of built-in stitches and embroidery designs, and high-quality results. With a 5” x 7” embroidery hoop, large color touchscreen display, and a maximum sewing speed of 850 stitches per minute, the Brother SE1900 is a top choice for both beginners and experienced crafters.

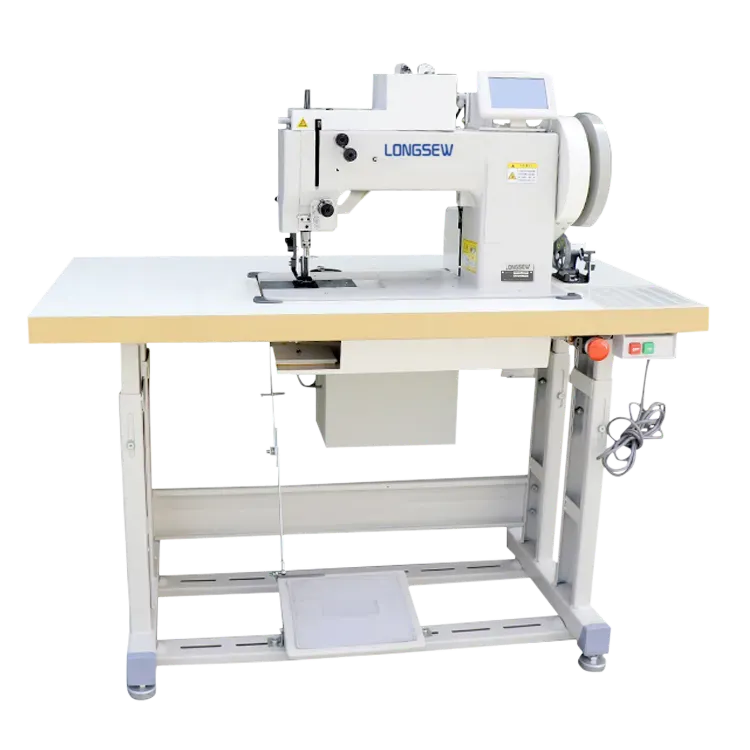

In the world of textile manufacturing and garment production, the evolution of sewing machines has been pivotal in enhancing efficiency and precision. One of the most significant developments in this domain is the hi-speed lockstitch sewing machine. This innovation has transformed the way fabrics are stitched together, enabling manufacturers to produce high-quality garments at an accelerated pace.

Another noteworthy application of the zigzag foot is its proficiency in finishing edges—an essential technique that helps prevent fraying. The smooth, continuous motion of the zigzag around the fabric perimeter helps secure the edges and provides a polished look to garments and accessories. This multifunctionality simplifies the sewing process, enabling makers to focus more on design and creativity rather than on tedious finishing techniques.

Typically, the machine head employs methods such as stitching, heat sealing, or gluing to close the bags. Each method has its advantages depending on the type of bag and the contents that need protection. For example, heat sealing is particularly effective for plastic bags as it provides a strong and waterproof closure. On the other hand, stitching is suitable for fabric bags, delivering durability and resistance against tearing during transport.

A flat bed sewing machine is characterized by its flat working surface, which is aligned with the needle and the feed dogs. This design allows fabrics to lie flat while being stitched, making it ideal for a wide range of sewing tasks. The flat bed design is the most common and traditional type of sewing machine, often used in both domestic and industrial settings.One of the primary applications of flat bed sewing machines is garment construction. These machines are perfect for sewing straight seams, hemming, and attaching zippers. They provide a stable surface that ensures smooth and even stitching, which is essential for creating high-quality clothing. From basic T-shirts to intricate dresses, flat bed sewing machines can handle various fabric types and thicknesses, making them incredibly versatile.Flat bed sewing machines are also widely used for quilting. The flat surface is ideal for piecing together quilt blocks and stitching quilt tops. Quilters can easily maneuver large pieces of fabric, ensuring precise and consistent stitches. Additionally, these machines are used in the creation of home décor items such as curtains, pillowcases, and tablecloths. Their ability to produce straight, even stitches makes them perfect for sewing long seams and hems.

When searching for an industrial leather sewing machine for sale, several features should be taken into consideration to ensure it meets your specific needs

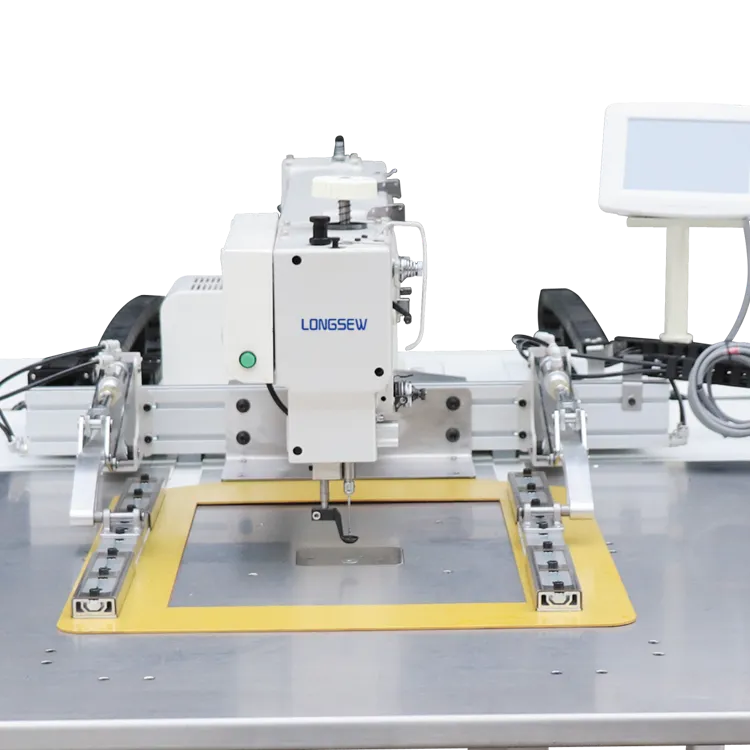

Moreover, the auto oil system contributes to improved stitch quality The container bag sewing machine is equipped with a heavy-duty sewing head that can handle the thick and tough material of the bags. With specialized needles and a powerful motor, these machines can stitch through multiple layers of fabric with ease. The stitching process is crucial in ensuring the strength and durability of the bags, as it prevents any leakage or breakage during transportation and storage.

Benefits of Using Handheld Sewing Machines for Thick Fabrics

One of the primary advantages of single needle sewing is its versatility. It can be employed across various fabric types, ranging from lightweight cotton to heavy denim, and can be adapted to a multitude of projects—from clothing to home décor. Moreover, many sewers appreciate the control that single needle sewing offers. Whether tackling a delicate fabric that requires a soft touch or a thicker material that demands strength, the single needle technique can adapt to the needs of each project. This adaptability has allowed it to remain relevant across generations, even as technology evolves.

single needle sewing

When discussing the price of the Durby Zig Zag Sewing Machine, it's important to recognize that prices can vary based on several factors, including location, retailer, and potential seasonal promotions. On average, customers might expect to pay between $200 to $400 for a new unit. Such a price point positions the Durby Zig Zag within a mid-range category, appealing to both hobbyists who are beginning their sewing journey and professionals who are seeking reliability and performance.

A double stitch machine, often referred to as a double needle sewing machine, utilizes two needles working in tandem, allowing it to create two parallel rows of stitching simultaneously. This feature is particularly advantageous for sewing thick materials, as it distributes the tension more evenly across the fabric. The dual needle setup not only saves time but also significantly improves the durability and strength of the seams, critical factors in the longevity of textile products.