Links:

У этаноле HPMC дае магчымасць ствараць растворы з добрымі вязкаснымі ўласцівасцямі, што робіць яго асабліва прывабным для фармацэўтычных прэпаратаў. Этанол, як органічны растваральнік, спрыяе распусканню HPMC, дзякуючы сваім полярным уласцівасцям. Гэта рашэнне часта ўжываецца ў формах, дзе патрабуецца высокая ступень растворанасці, асабліва для ўвязання актыўных рэчываў, якія інавацыйна перавозяцца ў гелях ці эмульсіях.

hpmc solubility in ethanol

Moreover, growth in industries such as construction and pharmaceuticals due to urbanization and increased health awareness has further bolstered the demand for HEC. Suppliers that leverage advanced technologies for polymer production and R&D can gain a competitive edge in the market.

The Role of HPMC as an Excipient in Pharmaceutical Formulations

.

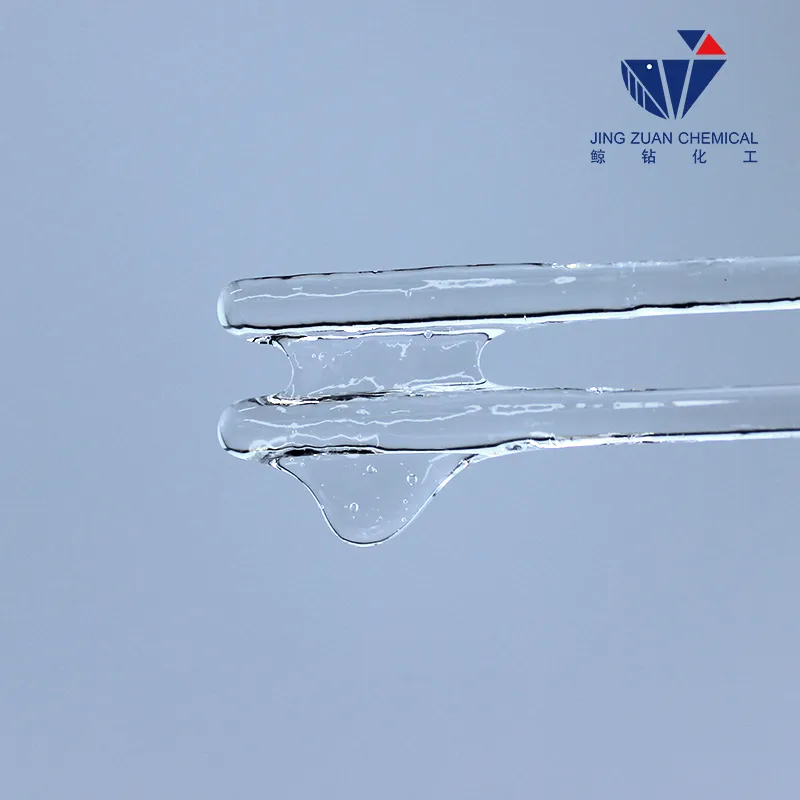

HPMC is known for its ability to form a gel and its thickening properties. These features make it an ideal ingredient in various products, particularly those requiring viscosity and stability. HPMC can dissolve in cold water, forming a transparent solution that is relatively stable, which sets it apart from many other cellulose derivatives.

The Chinese HPMC Market

china hpmc-hydroxypropyl methyl cellulose manufacturer

Another important property of HPMC is its rheological behavior. The polymer exhibits pseudoplasticity, meaning that its viscosity decreases under shear stress. This property is particularly useful in formulations requiring easy application and spreading. For instance, in the cosmetics industry, HPMC allows for smoother application of creams and lotions while providing stability to emulsions. Similarly, in the food industry, it is used as a thickening agent and stabilizer to improve texture without compromising flavor.

hpmc properties

In recent years, the construction and building materials industry has witnessed significant advancements due to the increasing demand for high-performance materials. One of the key innovations in this sector is redispersible polymer powder (RDP), a vital additive that enhances the properties of various construction products. This article delves into the role of RDP manufacturers, the importance of their products, and the factors to consider when selecting a supplier.

In personal care, HPMC is used in formulations such as shampoos, conditioners, and skin care products. Its thickening ability allows formulators to create products with desirable viscosities while maintaining a smooth application. Furthermore, HPMC dispersions in personal care products can enhance the sensory experience for the user, making the product feel luxurious and hydrating.

Hydroxypropyl Methylcellulose (HPMC) is a widely used polymer derived from cellulose. Its unique properties have made it popular in various industries, including pharmaceuticals, food, cosmetics, and construction. The identification and classification of HPMC are crucial for trade, regulation, and compliance with customs. This is where the Harmonized System (HS) code comes into play.

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer derived from cellulose. It has gained significant attention across various industries due to its versatile properties, particularly its viscosity characteristics. Viscosity, representing the thickness or resistance to flow of a fluid, plays a crucial role in determining the application and functionality of HEC.

Despite its broad range of applications, the popularity of HEC is not without challenges. The production and use of HEC must align with sustainability goals, as the environmental impact of cellulose sourcing and processing comes under scrutiny. Therefore, ongoing research is focused on developing more sustainable production methods and seeking alternative sources for cellulose derivatives.

Trong ngành thực phẩm, HPMC được sử dụng như một chất phụ gia để cải thiện kết cấu và ổn định của sản phẩm. Đặc biệt, HPMC được dùng trong các sản phẩm thực phẩm chế biến sẵn, vì khả năng giữ ẩm và tạo độ nhớt giúp sản phẩm giữ được độ tươi và hương vị lâu hơn. Cũng nhờ khả năng hòa tan trong nước, HPMC có thể dễ dàng sử dụng trong các công thức nấu ăn mà không làm thay đổi nhiều hương vị của thực phẩm.

is hpmc water soluble

Applications in Pharmaceuticals

Furthermore, ongoing research and innovation are likely to lead to the development of new formulations that enhance the performance characteristics of RDP polymers. For instance, incorporating nanomaterials or additives could further improve strength, flexibility, and other essential properties.

Different Grades of HPMC

Role in Food Products

hydroxypropyl methyl cellulose cas number

Food Industry Applications

The versatility of MHEC lies in its ability to be customized according to specific application requirements. Its non-ionic nature reduces the chances of adverse reactions with other chemical components, enhancing its compatibility in various formulations. Additionally, the use of MHEC can lead to improved product performance, reduced processing times, and lower overall costs by optimizing ingredient usage and enhancing end-product quality.

2. Online Marketplaces E-commerce platforms such as Amazon, Alibaba, and eBay have becoming increasingly popular for sourcing chemicals, including Cellosize HEC. These platforms can offer competitive prices and the convenience of home delivery. However, it's crucial to verify the credibility of the seller and check product reviews before making a purchase.

2. Water Retention HPMC possesses excellent water retention properties, which help in preventing early drying of the putty. This characteristic is essential for ensuring adequate hydration of the cement particles in the putty, leading to better curing and stronger adhesion to wall surfaces. Improved water retention also allows for a longer working time, making adjustments during application easier.

hpmc for wall putty

Hydroxypropyl methylcellulose (HPMC) is a cellulose derivative widely used in the pharmaceutical industry as an excipient. Being a semi-synthetic polymer, HPMC is valued for its unique properties that enhance the effectiveness and stability of various formulations. This article delves into the roles, benefits, and considerations associated with HPMC as an excipient.

Improving Workability

MHEC is derived from cellulose, a naturally occurring polymer found in the cell walls of plants. The modification process involves the introduction of methyl and hydroxyethyl groups to the cellulose backbone, imparting unique properties that enhance its functionality. The resulting structure is a white, odorless, and tasteless powder that is soluble in water, forming a clear and viscous solution upon dissolution.

3. Mu Ruganda

Tại Sao Nên Sử Dụng Hydroxyethyl Cellulose?

2. Cosmetics and Personal Care In the cosmetics industry, MHEC serves as a thickening agent and stabilizer in formulations like lotions, creams, and gels. Its emulsifying properties facilitate the uniform distribution of ingredients, contributing to improved texture and stability of personal care products. MHEC also enhances the sensory experience of users by providing a smooth and elegant feel upon application.

Китайські компанії, що виробляють HPMC, активно співпрацюють з міжнародними партнерами, що дозволяє їм впроваджувати нові технології та збільшувати свою присутність на світовому ринку. Таким чином, HPMC стає символом інновацій, які витворюють нові можливості у різних промисловостях.

4. Jiangxi Deyu Chemical Technology Co., Ltd. Focusing on eco-friendly production methods, Jiangxi Deyu is gaining recognition for its sustainable approach to HPMC manufacturing.

Hydroxypropyl Methylcellulose (HPMC) is a versatile excipient widely used in the pharmaceutical industry, particularly in the formulation of solid dosage forms such as tablets and capsules. As a cellulose derivative, HPMC provides a range of functional properties that enhance the performance and stability of pharmaceutical products.

.

3. Anti-Sagging Properties For wall tile installations, anti-sagging properties are of utmost importance. HPMC contributes to the structural integrity of the adhesive, preventing tiles from slipping or sliding down the wall after application. This feature is particularly beneficial when dealing with larger tiles that may be heavier and more prone to sagging.

hpmc tile adhesive

Hydroxyethyl Cellulose An Overview

Specialty Applications

RDP पाउडर (रेजिन-ड्रिपिशन पाउडर) का उपयोग निर्माण उद्योग में एक महत्वपूर्ण सामग्री के रूप में किया जाता है। यह एक विशेष प्रकार का पाउडर है जिसका मुख्य उपयोग कॉन्क्रीट और निर्माण परियोजनाओं में होता है। RDP पाउडर को उसके उच्च गुणवत्ता वाले बाइंडिंग और मजबूत निर्माण गुणों के लिए जाना जाता है। यह पाउडर, जब पानी के साथ मिलाया जाता है, तो यह एक आवश्यक बाइंडर के रूप में कार्य करता है, जो विभिन्न निर्माण सामग्रियों को एकसाथ लाने में मदद करता है।

.

RDP protokolu, API-lar, şəbəkə infrastrukturunun inkişafı və təhlükəsizlik tədbirləri ilə tamamilə birləşdirilərək istifadə olunur. Xüsusi təhlükəsizlik xüsusiyyətləri sayəsində, bütün məlumatlar şifrələnir və uzaq bağlantılar daha təhlükəsiz hala gətirilir. Bununla yanaşı, istifadəsi asan olduğu üçün RDP, həm fərdi istifadəçilər, həm də müəssisələr arasında populyarlaşmışdır.

rdp

Applications of HPMC Viscosity

Beyond these industries, HPMC has found applications in cosmetics, agriculture, and personal care products. In the cosmetic industry, it is harnessed for its film-forming properties, providing a smooth and aesthetically pleasing finish to products like shampoos and lotions. In agriculture, it acts as a soil conditioner, improving water retention and nutrient delivery.

Moreover, ongoing advancements in additive manufacturing and unique construction technologies may create new market opportunities for RDP. If these trends proliferate, they could influence overall demand, subsequently impacting pricing structures in the industry.

Understanding Hydroxyethyl Cellulose Price Trends

Hydroxypropyl Methylcellulose (HPMC) powder is a versatile and widely used excipient in both the pharmaceutical and food industries. As a semi-synthetic polymer derived from cellulose, HPMC has gained popularity due to its unique properties and functionalities that enhance the quality and performance of various products. This article explores the characteristics, applications, and benefits of HPMC powder.

One of the most significant advantages of HEC is its ability to retain moisture. This property is particularly important in the cosmetics industry, where it is commonly used in lotions, creams, and gels. By enhancing the texture and providing a smooth application, HEC helps to improve the overall experience of skincare products. Furthermore, its film-forming capability allows for improved adhesion and waterproofing effects in cosmetic formulations, resulting in long-lasting wear.

Methyl Hydroxyethyl Cellulose (MHEC) is a notable water-soluble polymer derived from cellulose, which has undergone chemical modification to enhance its properties. As a derivative of cellulose, MHEC retains many of the natural characteristics of its parent compound while gaining additional functionalities that make it valuable in various industries. With applications ranging from construction to pharmaceuticals, MHEC plays a crucial role in improving product performance and stability.

Key Properties of HPMC Dispersion

1. Bouwsector In de bouwindustrie wordt HMPC vaak gebruikt als een additief in mortels en coatings. Het verbetert de consistentie en verwerkbaarheid van de materialen, waardoor ze gemakkelijker aan te brengen zijn en een langere verwerkingstijd hebben. Bovendien helpt HMPC de hechtkracht van de mortel te verbeteren en verhoogt het de watervastheid.

As a company specialized in the chemical technology production for more than 15 years , our business scope is very broad .We have hydroxyethyl cellulose, hydroxypropyl methyl cellulose , redispersible powder , mortar bonding agent and tile bonding cellulose .About the hydroxyethyl cellulose , we have high quality hydroxyethyl cellulose .The hydroxyethyl cellulose price in our company are reasonable . If you are interesting in our product welcome to contact us!

HPMC for Sale A Versatile Ingredient for Various Applications