Links:

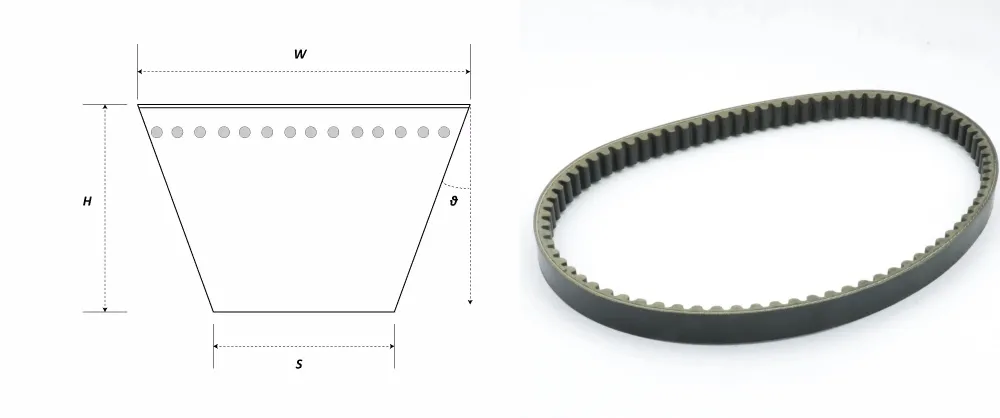

2. Reduced Slippage The wedging action of V belts into the pulley grooves provides superior grip, reducing the chances of slippage, which is critical for applications requiring precise motion.

1. Regular Inspections Check your PK belt every 5,000 to 7,500 miles. Look for signs of wear, including cracks, fraying, and tension.

Een slipende aandrijfriem kan verschillende negatieve gevolgen hebben

drive belt slipping

Applications of V-Belts

The material used in manufacturing timing belts significantly impacts their price. Most timing belts are made from rubber compounds or neoprene, reinforced with nylon or blending fiber materials to enhance durability. Higher quality belts may use superior materials that offer better resistance to wear and heat. Brands that invest in research and development to improve the longevity and performance of their products tend to charge more. Additionally, specialized timing belts for high-performance vehicles or those designed to withstand extreme conditions may also carry a higher price tag.

Key Features and Benefits

The timing belt industry is at a crossroads, facing numerous challenges while also presenting exciting opportunities for innovation and growth. As vehicle technology advances and environmental concerns gain importance, timing belt manufacturers must remain agile, forward-thinking, and committed to continuous improvement. With the right strategies and adaptations, the timing belt industry can thrive in the future automotive landscape, ensuring its relevance in a rapidly changing environment.

Furthermore, in the food industry, poly belting is often favored due to its hygienic properties. It can be manufactured to meet food safety standards, ensuring that it does not harbor bacteria or contaminants. Polyurethane belts can also withstand high-pressure cleaning processes without compromising their integrity, making them ideal for food processing and packaging applications.

To ensure the longevity and performance of the 2GT timing belt, regular maintenance and inspection are crucial. Here are some practical tips

3. Install the New Belt Follow the belt routing diagram often found under the hood or in the owner's manual. Ensure that the belt is seated properly on all pulleys.

Ribbed drive belts are vital components in modern machinery, offering enhanced efficiency, flexibility, and durability. Their unique design allows for multiple applications across various industries, making them indispensable in today's mechanical landscape. As technology continues to evolve, the development of ribbed drive belts will likely expand, further enhancing their performance and applicability. Understanding both their mechanical functions and maintenance requirements will ensure that they continue to provide reliable service for years to come.

In summary, rubber V belts are vital components in the world of industrial machinery and automotive applications. Their unique design and composition provide numerous advantages, including flexibility, shock absorption, and cost-effectiveness. As industries continue to evolve, the role of rubber V belts will remain crucial in ensuring the reliable transmission of power. Investing in quality rubber V belts and regular maintenance can lead to enhanced performance and longevity, ultimately benefiting both manufacturers and consumers alike.

Every Audi model comes equipped with a timing belt that plays a vital role in the engine’s overall performance. The timing belt drives the camshaft, which controls the opening and closing of the engine's valves. This precise timing is crucial, as even a slight misalignment can result in poor engine performance, reduced fuel efficiency, and ultimately catastrophic engine failure.

- Regular Inspections Perform visual checks for wear, cracks, or fraying of the belt. Look for signs of misalignment or improper tension, which can lead to premature failure.

3. Reassembly Once the new timing belt is in place, all components need to be reassembled, and the engine should be started to check if it runs smoothly.

Moreover, flat belts contribute to quieter operation compared to other power transmission methods, such as chain drives. This characteristic is particularly important in settings where noise reduction contributes to a safer and more pleasant work environment.

To understand the fan belt's role, we must first consider its basic function. The fan belt, also known as the serpentine belt in many modern trucks, connects various engine components to the crankshaft. Its primary purpose is to drive the vehicle’s cooling fan, which is essential for regulating the engine temperature. In addition, the fan belt powers other critical accessories, including the alternator, power steering pump, and air conditioning compressor. This multifunctionality underscores its importance in the overall operation of a truck.

Pricing can vary based on geographical location. Regions with strong automotive manufacturing bases might see a higher concentration of suppliers and potentially lower prices due to competition. Conversely, remote areas may have limited access to quality belts or fewer suppliers, resulting in higher prices. Local market conditions and distribution costs can thus influence how much you pay for poly V belts.

- Professional Assistance If you’re not comfortable inspecting or replacing the timing belt yourself, seek professional assistance. A certified mechanic will have the expertise to handle this critical task efficiently.

- Tension Checks Ensure that the belt is properly tensioned. A belt that is too loose may slip, while one that is too tight can cause excessive wear on both the belt and the pulleys.

The workforce in the manufacturing belt is also evolving. Initiatives aimed at workforce development and education are being implemented to equip workers with the necessary skills for the modern manufacturing landscape. Community colleges and vocational training programs are partnering with local industries to ensure that workers are prepared for the jobs of the future. This emphasis on education not only supports economic revitalization but also empowers individuals to succeed in a rapidly changing job market.

Maintenance and Replacement

The V Face Lift Massager Belt offers an array of benefits that can transform your skincare routine

The LB7 engine, a highly regarded diesel powerplant, is known for its reliability and performance in various General Motors vehicles, especially the GMC and Chevrolet trucks. One critical component of this engine's functionality is the serpentine belt. This article will delve into the importance of the serpentine belt in the LB7 engine, maintenance tips, and signs indicating when it needs replacement.

5. Lubrication Unlike chains, motorbike belts do not require regular lubrication. However, ensuring that the adjacent pulleys are well-lubricated can enhance performance.

Řemen serpentinový Klíčový prvek pro správnou funkci motoru

Importance of Timely Replacement

The synchronization achieved by the timing belt is vital for the engine to function properly. When the crankshaft rotates, it drives the pistons up and down. The camshaft, meanwhile, regulates the opening and closing of the engine's valves. If these two components are not perfectly aligned—if, for instance, the timing belt were to slip or break—the engine could experience severe issues, including misfires, loss of power, and in extreme cases, catastrophic engine failure.

3. Cleanliness Dirt and debris can cause unnecessary wear. Clean the belt and pulleys regularly to extend the lifespan of the parts.

3. Electrodomésticos Muchos electrodomésticos, como lavadoras y secadoras, utilizan sistemas de poleas con correa para mover los tambores y otros elementos mecánicos.

Benefits of Using Poly Belt 7PK 612

3. Flexibility The flexibility of neoprene allows the timing belt to navigate around pulleys easily, providing efficient power transmission without slipping. This adaptability also aids in the installation of belts in compact spaces.

3. Reduced Wear on Components Compared to gears, belts can help reduce wear and tear on mechanical components since they dampen shocks and vibrations.

1. Power Steering Pumps The 8PK belt often drives the power steering pump, ensuring smooth steering capability, especially in larger vehicles or those designed for heavy-duty operations.

One of the primary concerns for many car owners is maintaining organization and maximizing utility within the vehicle. Items such as trunk organizers, backseat storage solutions, and console organizers can help keep your car neat and tidy. Products like collapsible storage bins and mesh organizers can fit into your trunk or backseat, allowing you to store groceries, tools, or sporting equipment without clutter.

Choosing the Right Replacement

Maintenance of Flat Timing Belts

flat timing belt

V-belts are mechanical components designed to transmit power between rotating shafts. Their distinctive V shape enables them to maintain a tight grip on pulleys, reducing slippage and inefficiency. This design feature makes them ideal for various applications, including engines, alternators, water pumps, and air conditioning compressors. V-belts' capacity to manage high torque and consistent force transmission under varying loads has contributed to their widespread adoption in automotive applications worldwide.

The Importance of V-Belts in Vehicle Performance

In the ever-evolving landscape of technology and society, the 10PK1480 initiative stands as a testament to innovation, collaboration, and the crucial need for a sustainable future. This initiative, although abstract in its numerical designation, encapsulates a wide range of interconnected goals aimed at addressing some of the most pressing challenges facing humanity today.

While GT2 timing belts are designed for durability, proper maintenance is essential to ensure their longevity and performance. Regular inspections for wear and tear, correct tensioning, and keeping them free from debris can significantly prolong their lifespan. Furthermore, aligning the belt properly with its pulleys helps to avoid uneven wear or potential failure.

One of the standout features of a motorcycle zip belt is its functional design. Many models are designed with multiple pockets or compartments, allowing riders to store small essentials like wallets, phones, and even small tools right on their person. This functionality is particularly appealing for long rides where access to essentials without needing to stop is a critical consideration.

- Industrial Equipment These belts are used in conveyor systems, processing machines, and other industrial machinery where reliable power transmission is crucial.

Applications of Toothed Belts

To ensure the longevity and efficiency of conveyor belt teeth, regular maintenance is essential. This includes routine inspections to check for wear and tear, ensuring that teeth are not broken or excessively worn. Maintaining proper tension in the conveyor system can also prevent issues related to misalignment, which can affect the performance of the teeth.

Synchronous Belts for Sale A Comprehensive Guide

I landbruket er maskinbelter essensielle for drift av traktorer og andre landbruksmaskiner. De sørger for at maskinene kan utføre oppgaver som pløying, høsting og frakt av varer effektivt.

A common styling trick is to layer a cozy cardigan or a chic denim jacket over loungewear, cinching it in at the waist with a PJ Belt to create a flattering silhouette. This not only adds interest to your outfit but also transitions seamlessly from a relaxed home setting to running errands or casual outings.

Applications of the B60 V-Belt

v-belt b60

Round drive belts, often referred to as round belts, play a critical role in various applications within mechanical systems. These flexible components, made from rubber, polyurethane, or leather, are integral to the operation of machinery across multiple industries. Understanding the design, function, and applications of round drive belts can provide valuable insights into their importance and usage.