Links:

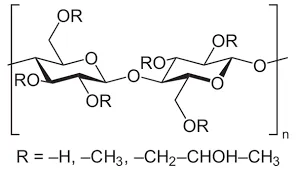

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer widely used in various industries due to its unique properties. It is derived from cellulose, one of the most abundant organic polymers found in nature, primarily sourced from wood pulp and cotton. The formation of hydroxyethyl cellulose involves the substitution of hydroxyethyl groups onto the hydroxyl groups of cellulose, enhancing its functionality and applicability in numerous products.

Applications in Pharmaceuticals

The benefits of HPMC sheets are numerous. Their biocompatibility makes them safe for use in sensitive applications such as pharmaceuticals and food products. Their ability to absorb water and swell allows them to function effectively as binding agents and stabilizers. Furthermore, HPMC’s environmental advantages, being biodegradable and derived from renewable resources, align perfectly with the growing emphasis on sustainability in today’s market.

Exploring Hydroxyethyl Cellulose Applications and Benefits

In the pharmaceutical industry, HPMC serves multiple roles. It is commonly used as a binder in tablet formulations, enhancing the mechanical strength and disintegration properties of tablets. HPMC is also utilized in drug delivery systems due to its ability to form matrices that control the release of active pharmaceutical ingredients. This controlled release not only improves bioavailability but also extends the duration of drug action, minimizing the need for frequent dosing. Furthermore, HPMC is employed in ocular solutions, where it aids in providing lubrication and enhancing the comfort of contact lenses.

HPMC is derived from natural cellulose, a polymer found in plant cell walls. Through a series of chemical modifications, cellulose is transformed into HPMC, imparting it with various functional properties. HPMC is known for its ability to bind moisture, provide viscosity, and act as a stabilizer, making it an ideal ingredient in multiple applications. Its use spans across various sectors, including pharmaceuticals where it serves as a binding agent in tablets, to construction where it is used in cement-based adhesives and mortars.

In conclusion, buying hydroxyethyl cellulose can be done through a variety of channels, including online retailers, specialty chemical suppliers, local distributors, and trade shows. Regardless of the purchasing route you choose, it's vital to conduct thorough research, verify supplier credibility, and ensure that the product meets your specific needs. With the right information and resources, you can successfully source hydroxyethyl cellulose for your applications.

5. Compatibility HPMC is compatible with various formulations, including cement-based, gypsum-based, and other polymer modifications. This versatility makes it suitable for a wide range of applications, from stucco and plaster to joint fillers and self-leveling compounds.

5. Allow time for the polymer to dissolve - HEC is a high-molecular-weight polymer, so it may take some time to fully dissolve in water. It is recommended to let the mixture sit for a few hours or overnight to ensure complete dissolution.

One of the most significant attributes of HPMC is its ability to form a gel-like consistency when mixed with water. This property makes it an excellent thickening agent, allowing for improved texture and viscosity in products. HPMC is also known for its film-forming capabilities, which provide a protective barrier in various applications. Additionally, HPMC is non-ionic, which means it does not carry any charge, making it compatible with a wide range of active ingredients without destabilizing formulations.

Conclusion

Overall, HPMC grades offer a wide range of benefits and applications across various industries. Whether you are looking to improve the performance of your construction materials, enhance the stability of your cosmetic products, or optimize the flow of your pharmaceutical formulations, there is a suitable HPMC grade for your needs.

Benefits of High Viscosity HPMC

In the food industry, HPMC serves as a fat replacer and thickener, enhancing the texture and stability of food products. It is often found in low-fat or reduced-calorie foods, where it mimics the mouthfeel of fat while contributing fewer calories. Additionally, HPMC is deemed safe for consumption, which adds to its appeal as a food additive.

Which is the best? Both are excellent choices

Key Applications of VAE Redispersible Powder

Moreover, RDPs serve to enhance water resistance and reduce permeability. This is essential in coatings and waterproofing applications, where moisture ingress can lead to significant damage and deterioration. By incorporating RDPs, manufacturers can create products that maintain their performance even under challenging weather conditions, ensuring long-term effectiveness.

redispersible polymer powder wikipedia

HPMC solution, or hydroxypropyl methylcellulose solution, is a commonly used material in various industries due to its versatility and unique properties. This article will explore the composition, benefits, and applications of HPMC solution.

3. Supplier Reputation Choosing a reputable supplier is vital for ensuring the quality and authenticity of HPMC. Look for suppliers with industry certifications, positive customer reviews, and a proven track record in providing high-quality products.

Hydroxypropyl methylcellulose (HPMC) is a versatile cellulose ether that has gained significant attention across various industries due to its unique properties and multifaceted applications. As a non-ionic polymer, HPMC is derived from cellulose, and its modification introduces different functional groups, making it suitable for a wide range of uses. The different grades of HPMC have varying physical and chemical properties, which allow them to cater to specific applications in pharmaceuticals, food preparation, construction, and many other fields.

HEC cellulose is also gaining attention in the food industry, where it is used as a thickening agent and stabilizer in sauces, dressings, and ice creams. Its non-toxic nature and ability to improve texture make it an attractive ingredient for food manufacturers.

What is the Viscosity Range of HPMC?

Hydroxyethyl cellulose (HEC) is a non-ionic, water-soluble polymer that is widely used in various industries due to its ability to modify the rheological properties of solutions. One of the key characteristics of HEC is its viscosity, which plays a crucial role in determining its effectiveness in different applications.In conclusion, hydroxyethyl cellulose (HEC) is a versatile and valuable derivative of cellulose with a broad range of applications across various industries. From construction and personal care to food and pharmaceuticals, its unique properties make it an essential component in enhancing product quality and functionality. As environmental considerations continue to shape industry practices, focusing on sustainable production methods for HEC will further solidify its position as a vital ingredient in modern formulations. The ongoing innovation and research surrounding HEC promise a future where both efficacy and sustainability can coexist.

High viscosity HPMC is a modified cellulose compound that possesses a higher molecular weight, resulting in increased viscosity levels compared to standard grades. This elevated viscosity is a result of the hydroxypropyl and methyl substitutions on the cellulose backbone, which allow for improved water retention and gel formation. The thickening properties of high viscosity HPMC are particularly valued in formulations where a significant level of viscosity is required, such as in pharmaceuticals, cosmetics, food products, and construction materials.

hydroxy ethyl cellulose uses. Additionally, HEC can also be used as a viscosity modifier in liquid formulations, providing the desired consistency and flow properties.

Hydroxypropyl Methylcellulose (HPMC) is a widely used cellulose ether, known for its versatile properties in various applications, from pharmaceuticals to food products. One of the critical aspects of utilizing HPMC effectively is understanding its solubility characteristics, which can be found in the HPMC solubility chart. This chart serves as a vital tool for formulators, offering insights into HPMC's behavior in different solvents and conditions.

HPMC is available in several grades, each defined by its viscosity, degree of substitution, and solubility characteristics. The choice of grade is pivotal because each one is tailored to meet specific formulation needs. The common parameters influencing the classification of HPMC grades are

One of the key characteristics of MHEC is its ability to act as a thickening agent and stabilizer in many different products. In the construction industry, MHEC is used in cement and mortar applications to improve workability, water retention, and adhesion. This helps to enhance the overall strength and durability of the final product.

Hydroxypropyl Methylcellulose (HPMC) is a semisynthetic polymer derived from cellulose, widely utilized in various industries due to its versatile properties. This compound, known for its thickening, emulsifying, and film-forming capabilities, has found applications across multiple fields, including pharmaceuticals, food production, cosmetics, and construction.